Plane network impact wave loading device and making method of device

A technology of loading device and planar network, which is applied in blasting and other directions, and can solve the problems of large size and high manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

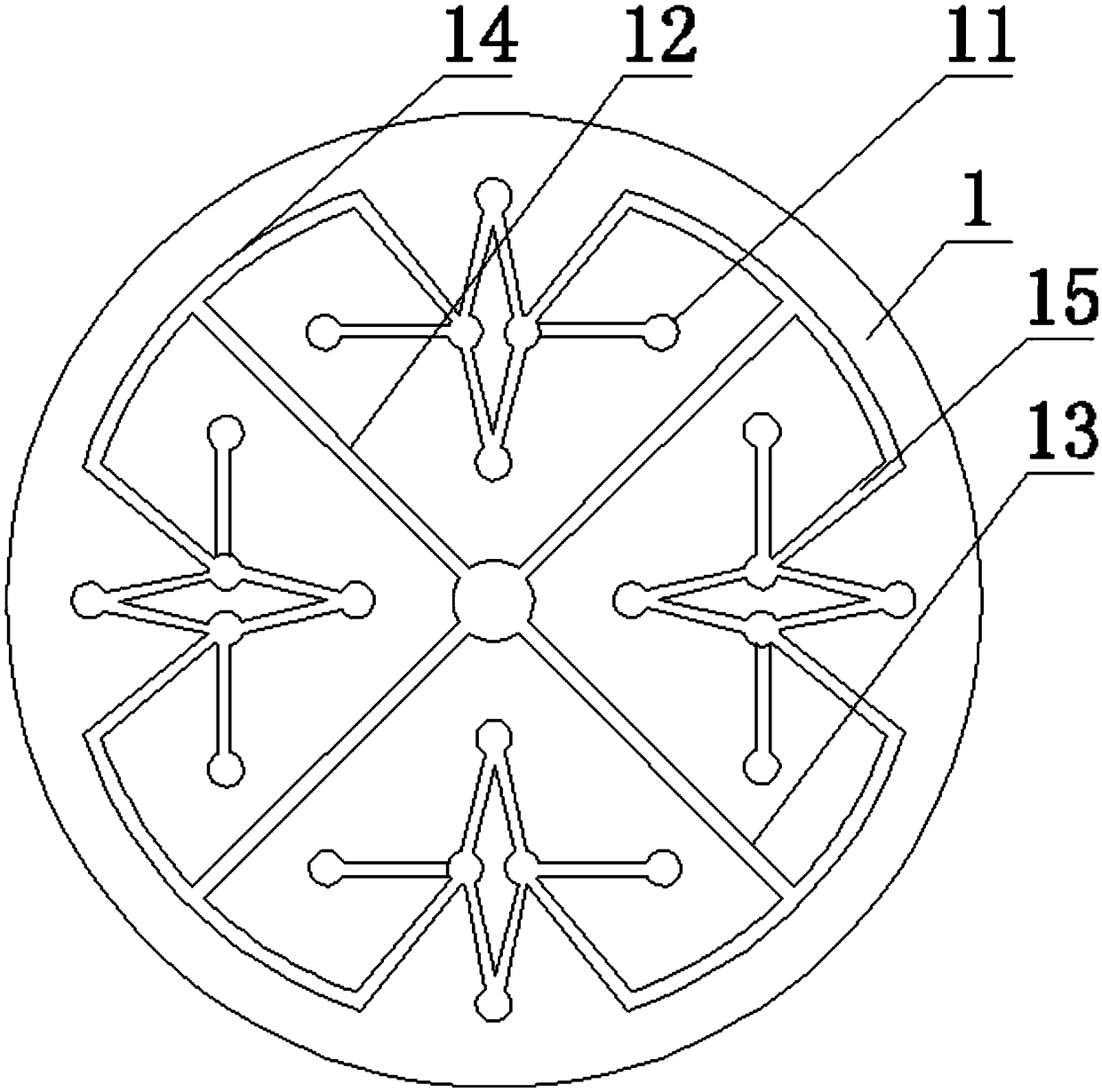

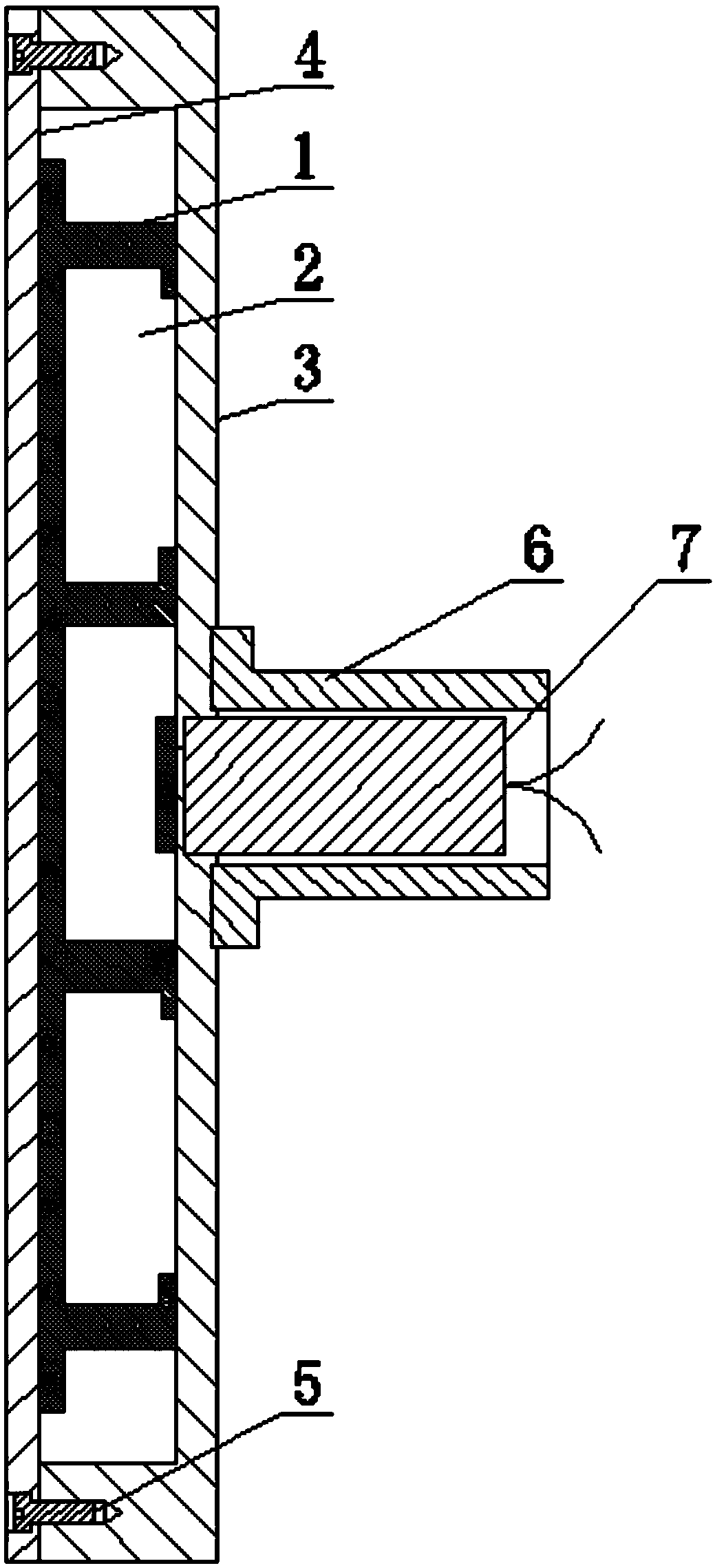

[0046] Such as figure 1 and figure 2 As shown, a flat network shock wave loading device, the loading device includes a network board substrate 1, an attenuation layer 4 and an installation sleeve 3, and the network board substrate 1, attenuation layer 4 and installation sleeve 3 are connected by screws 5. In one piece, the network board substrate 1 and the attenuation layer 4 are made of 2A12 aluminum alloy.

[0047] In the above scheme, the 2A12 aluminum alloy is derived from GB / T 3191-2010, and the materials of the network board substrate 1 and the attenuation layer 4 are both 2A12 aluminum alloy in order to utilize the processing performance of the 2A12 aluminum alloy and the conductivity of the material Performance, thermal conductivity, shock wave attenuation ability, etc., through good machinability to obtain higher processing accuracy of size and surface quality, through the material's electrical conductivity, thermal conductivity, shock wave attenuation ability, etc....

Embodiment 2

[0050] Such as figure 1 and figure 2 As shown, this embodiment is further limited on the basis of embodiment 1: as a further technical solution of the loading device:

[0051] Specifically, it is set as follows: the attenuation layer 4 is in the shape of a plate, the installation sleeve 3 is in the shape of a cover, the opening end of the installation sleeve 3 is fastened on the attenuation layer 4, and the network board substrate 1 is clamped on the Within the space enclosed by the attenuation layer 4 and the installation sleeve 3, the attenuation layer 4 and the installation sleeve 3 are connected by screws 5;

[0052] A medicine filling space 2 for filling medicine is also arranged on the grid plate substrate;

[0053] It also includes a mounting seat 6 installed on the mounting sleeve 3 for installing the detonator 7, the drug filling space 2 is located in a circular area, and the mounting seat 6 is located at the center of the circular area, The drug filling space 2 i...

Embodiment 3

[0067] At the same time, this embodiment provides a method for preparing a planar network shock wave loading device. The preparation method is used to prepare the loading device provided by any one of the above embodiments, including the steps of component processing, drug filling Step and component assembly step, the component processing step includes processing the network board substrate 1, the installation sleeve 3 and the attenuation layer 4, and the network board substrate 1 and the attenuation layer 4 are all processed by 2A12 aluminum alloy. This preparation method is the preparation method of the above loading device.

[0068] As a further technical solution of the preparation method, in the component processing step, processing the network board substrate 1 includes the following steps in sequence: processing of the network board substrate 1 and surface treatment process;

[0069] The processing is to obtain the network board substrate 1 of designed size and surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com