Preparation method of composite film with high light transmittance and excellent electromagnetic shielding performance

An electromagnetic shielding, high light transmittance technology, applied in the fields of magnetic field/electric field shielding, cable/conductor manufacturing, circuits, etc., can solve the problems of limited electromagnetic compatibility and protection applications, and achieve excellent electromagnetic shielding efficiency and excellent conformal ability. , the effect of high light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

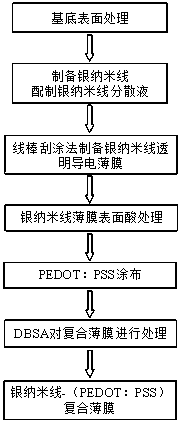

[0032] Such as figure 1 As shown, a method for preparing a composite film with both high light transmittance and excellent electromagnetic shielding performance requires surface treatment of the substrate, preparation of silver nanowires and preparation of silver nanowire dispersions, and preparation of transparent silver nanowires by bar scraping. Conductive film, surface acid treatment of silver nanowire transparent conductive film, PEDOT:PSS coating, DBSA treatment of composite film, drying to obtain silver nanowire-(PEDOT:PSS) composite film, specifically including the following five steps:

[0033] Step 1, selecting a material with optical transparency as the substrate, and treating the surface of the substrate to improve the adhesion between the silver nanowire and the substrate;

[0034] Among them, the substrate can be selected from one of glass, polyethylene, polyethylene terephthalate, polycarbonate, etc., and the treatment process is as follows:

[0035] a. Cut the...

Embodiment

[0049] A method for preparing a composite film with high light transmittance and excellent electromagnetic shielding performance, such as figure 1 As shown, a polyethylene terephthalate (PET) substrate was used, and the PET substrate was cut into small pieces with a size of 100 mm × 100 mm, placed in acetone and absolute ethanol in turn, and ultrasonically treated for 30 min, respectively. After being rinsed with deionized water and blown dry, the surface of the PET substrate was treated with an oxygen plasma cleaning machine for 10 minutes, and finally the substrate was cleaned with deionized water, and the surface-treated substrate was obtained after drying.

[0050] At the same time, silver nanowires with a length of 25±3µm and a diameter of 30±2nm were prepared by chemical methods, and dispersed in a mixed solution of water and isopropanol (the volume ratio of water and isopropanol was 1:1). The concentration of silver nanowires is 1 mg / ml. After completing the surface tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com