A method for preparing a solid electrolyte interface film on a lithium metal surface

A technology of solid electrolyte and interfacial film, applied in the direction of non-aqueous electrolyte battery, electrolyte battery manufacturing, lithium battery, etc., can solve the problems of harsh preparation conditions of artificial SEI film, high cost of high-concentration electrolyte, complicated process, etc., to achieve the regulation of lithium Ion deposition, improvement of safety performance and cycle performance, and the effect of mature technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

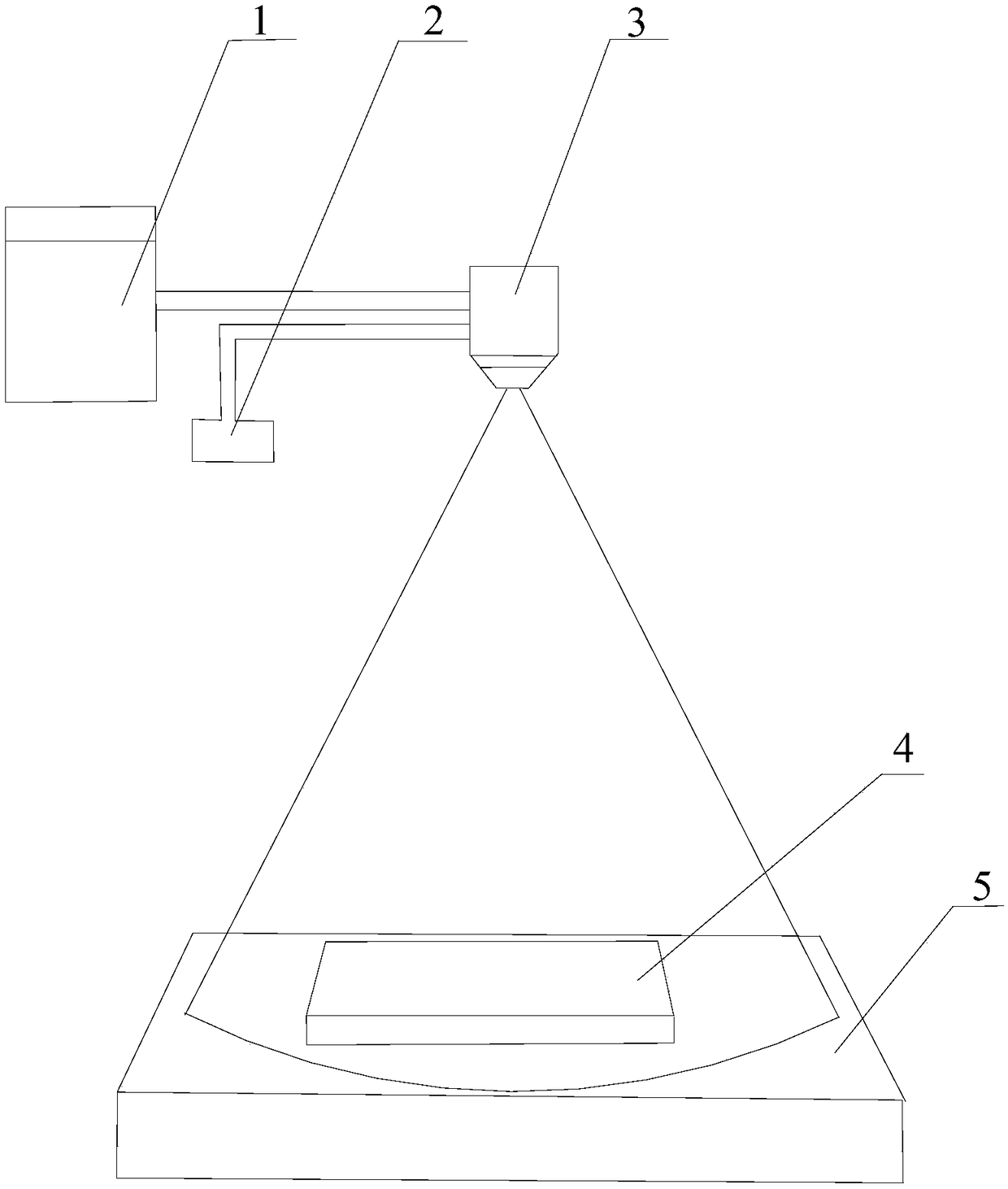

Embodiment 1

[0037] Lithium bis(trifluoromethylsulfonyl)imide is dissolved in 1,3-dioxolane and ethylene glycol dimethyl ether (volume ratio 1:1), and lithium nitrate and fluoroethylene carbonate are added to form a precursor solution, the concentration of lithium bis(trifluoromethylsulfonyl)imide is 0.1molL -1 , the concentration of lithium nitrate is 0.01mol L -1 , the concentration of fluoroethylene carbonate is 0.02mol L -1 , the lithium sheet was placed on the surface of the heating table and kept at a constant temperature of 180°C. The peristaltic pump of the spray generator operates at a flow rate of 2.5mLmin -1 Transport the precursor solution, atomize it into droplets through the ultrasonic nozzle, and carry it with the carrier argon gas 100Lh -1 Spray on the surface of the heated lithium sheet, control the spraying time for 3s and stop the heating on the heating table 15s after the spraying ends. After cooling, a composite lithium metal pole piece with a solid electrolyte int...

Embodiment 2

[0039] Lithium hexafluorophosphate is dissolved in ethylene carbonate and diethyl carbonate (volume ratio 2:3), and lithium nitrate and vinylene carbonate are added to form a precursor solution. The concentration of lithium hexafluorophosphate is 0.2mol L -1 , the concentration of lithium nitrate is 0.05mol L -1 , the concentration of vinylene carbonate is 0.02mol L -1 , the lithium sheet was placed on the surface of the heating table and kept at a constant temperature of 200°C. The peristaltic pump of the spray generator with a flow rate of 1.0mLmin -1 Transport the precursor solution, atomize it into droplets through the ultrasonic nozzle, and carry it with the carrier argon gas 200Lh -1 Spray on the surface of the heated lithium sheet, control the spraying time for 5s and stop the heating on the heating table 30s after the spraying ends. After cooling, a composite lithium metal pole piece with a solid electrolyte interface film is prepared. Install a lithium metal symme...

Embodiment 3

[0041] Lithium bisoxalate borate was dissolved in ethyl methyl carbonate and tetrahydrofuran (volume ratio 2:1), and fluoroethylene carbonate and lithium polysulfide (Li 2 S 6 ) to form a precursor solution, the concentration of bisoxalate lithium borate is 0.5mol L -1 , the concentration of fluoroethylene carbonate is 0.5mol L -1 , the concentration of lithium polysulfide is 0.05mol L -1 , the lithium sheet was placed on the surface of the heating table and kept at a constant temperature of 400°C. The peristaltic pump of the spray generator operates at a flow rate of 0.5mLmin -1 Transport the precursor solution, atomize it into droplets through the ultrasonic nozzle, and carry it with the carrier argon gas 600Lh -1 Spray on the surface of the heated lithium sheet, control the spraying time for 10s and stop the heating on the heating table after the spraying ends for 5s. After cooling, a composite lithium metal pole piece with a solid electrolyte interface film is prepare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com