Novel calcium magnesium silicate and silk fibroin composite porous scaffold and preparation method thereof

A technology of silk fibroin and magnesium silicate, applied in the fields of medical science, prosthesis, tissue regeneration, etc., to achieve the effect of low production cost, simple process and short time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

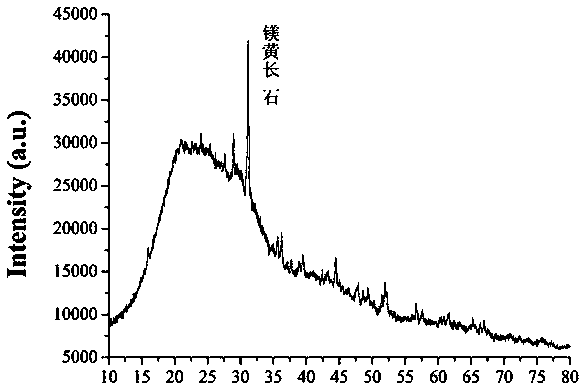

Embodiment 1

[0028] A novel calcium magnesium silicate and silk fibroin composite porous scaffold and a preparation method thereof are provided. Add magnesian feldspar powder into n-butanol at a mass volume ratio of 2g:100mL, place it in a ball mill jar for mechanical ball milling at a speed of 200rpm for 2h; then ultrasonically disperse the milled slurry with an ultrasonic power of 35W and a frequency of 40kHz; after ultrasonication for 10min, at a stirring speed of 200rpm, add the above-mentioned dispersion solution dropwise to the silk fibroin solution with a mass fraction of 10% at a volume ratio of 4:2 to control the mass ratio of feldspar to silk fibroin The ratio is 10:100; the mixed suspension is placed in a refrigerator at -20°C for 10 hours, then thawed at room temperature for 6 hours to obtain a white silk fibroin scaffold, and the scaffold is cleaned with deionized water and n-butanol. The scaffold is freeze-dried to obtain a composite porous bone tissue engineering scaffold. ...

Embodiment 2

[0031] A novel calcium magnesium silicate and silk fibroin composite porous scaffold and a preparation method thereof are provided. Add wollastonite powder into n-butanol at a mass volume ratio of 12g: 100mL, place it in a ball mill jar for mechanical ball milling at a speed of 200rpm for 2 hours; then ultrasonically disperse the milled slurry with an ultrasonic power of 35W, The frequency is 40kHz; after ultrasonication for 10min, at a stirring speed of 200rpm, the above-mentioned dispersion liquid is added dropwise to the silk fibroin solution with a mass fraction of 15% at a stirring speed of 200rpm to control the transformation of wollastonite and silk fibroin. The mass ratio of the protein was 40:100; the mixed suspension was frozen in a refrigerator at -15°C for 12 hours, and then thawed at room temperature for 6 hours to obtain a white silk fibroin scaffold, which was washed with deionized water and washed. After n-butanol, the scaffold was freeze-dried to obtain a comp...

Embodiment 3

[0033] A novel calcium magnesium silicate and silk fibroin composite porous scaffold and a preparation method thereof are provided. The magnesium-doped calcium silicate powder was added to n-butanol at a mass volume ratio of 20g: 100mL, and placed in a ball mill jar for mechanical ball milling at a speed of 200rpm for 2 hours; then the milled slurry was ultrasonically dispersed, and the ultrasonic power was 35W, the frequency is 40kHz; after ultrasonication for 10min, at a stirring speed of 200rpm, the above dispersion liquid is added dropwise to the silk fibroin solution with a mass fraction of 20% at a stirring speed of 200rpm to control the magnesium-doped silicic acid The mass ratio of calcium to silk fibroin is 50:100; the mixed suspension is placed in a -10°C refrigerator for 16 hours, and then thawed at room temperature for 6 hours to obtain a white silk fibroin scaffold, which is cleaned with deionized water Scaffolds were washed with n-butanol and freeze-dried to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| compressive modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com