Preparation method of coated antibacterial ceramics and coated antibacterial ceramics

A technology of antibacterial ceramics and ceramics, applied in the preparation of coated antibacterial ceramics and the field of coated antibacterial ceramics, can solve the problems of high production equipment, harsh production conditions, and difficult to achieve, and achieves a wide range of applicable materials, low operating equipment costs, and easy industrialization. The effect of promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

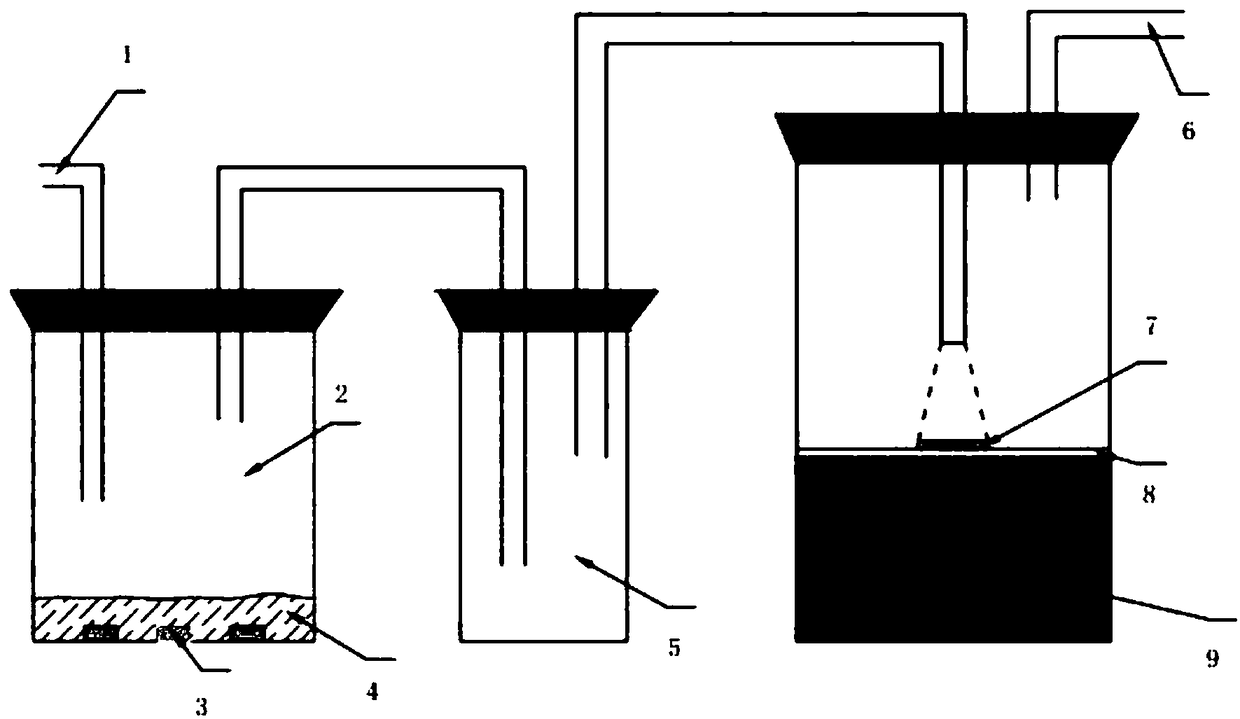

[0057] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings. The ultrasonic spray pyrolysis method is characterized by fine atomized particles, deep and uniform coating, and has the advantages of low price and high controllability, and can be used in industrial production. The present invention proposes a kind of preparation method of coating antibacterial ceramics, it comprises the following steps:

[0058] S1. Preparation of doped modified sol: adding soluble titanate, surfactant, and at least one metal ion compound for doping to the solvent, and in the presence of a chelating agent, to prepare a doped modified sol;

[0059] S2. Spray the doped modified sol onto the ceramic surface: spray the doped modified sol prepared in step S1 onto the ceramic surface by an ultrasonic spraying method to form a uniform and dense doped...

Embodiment 1

[0072] S1. Measure 10 mL of tetrabutyl titanate into a pear-shaped funnel at room temperature, slowly add it to 70 mL of absolute ethanol, stir for 30 min, and mix well to form solution A;

[0073] Add 4mL of glacial acetic acid into 70mL of absolute ethanol, add 0.001mol of cobalt nitrate, and add 0.25g of sodium dodecylbenzenesulfonate as a surfactant, and stir until the powder is evenly dissolved to form solution B;

[0074] Slowly titrate solution A into solution B, and stir for 30 min after the dropwise addition to obtain a sol.

[0075] S2. Put the tiles into deionized water, absolute ethanol, and acetone and clean them in an ultrasonic cleaner for 30 minutes each, and dry them with absorbent cotton for later use;

[0076] Pour the sol into the ultrasonic spray pyrolysis device, and place the pretreated ceramic tile sample on the ceramic substrate substrate on the heating device, and the substrate temperature is controlled at about 60°C;

[0077] Spray the coating for 4...

Embodiment 2-6

[0080] Similar to the steps of Example 1, Examples 2-6 are realized only by adjusting the type and doping amount of the metal ion compound in Step S1, and the other conditions remain unchanged. Specifically, the doping amount of cobalt nitrate in Examples 2, 3, 4, 5, and 6 is 0.002mol, 0.004mol, 0.006mol, 0.008mol, 0.01mol,

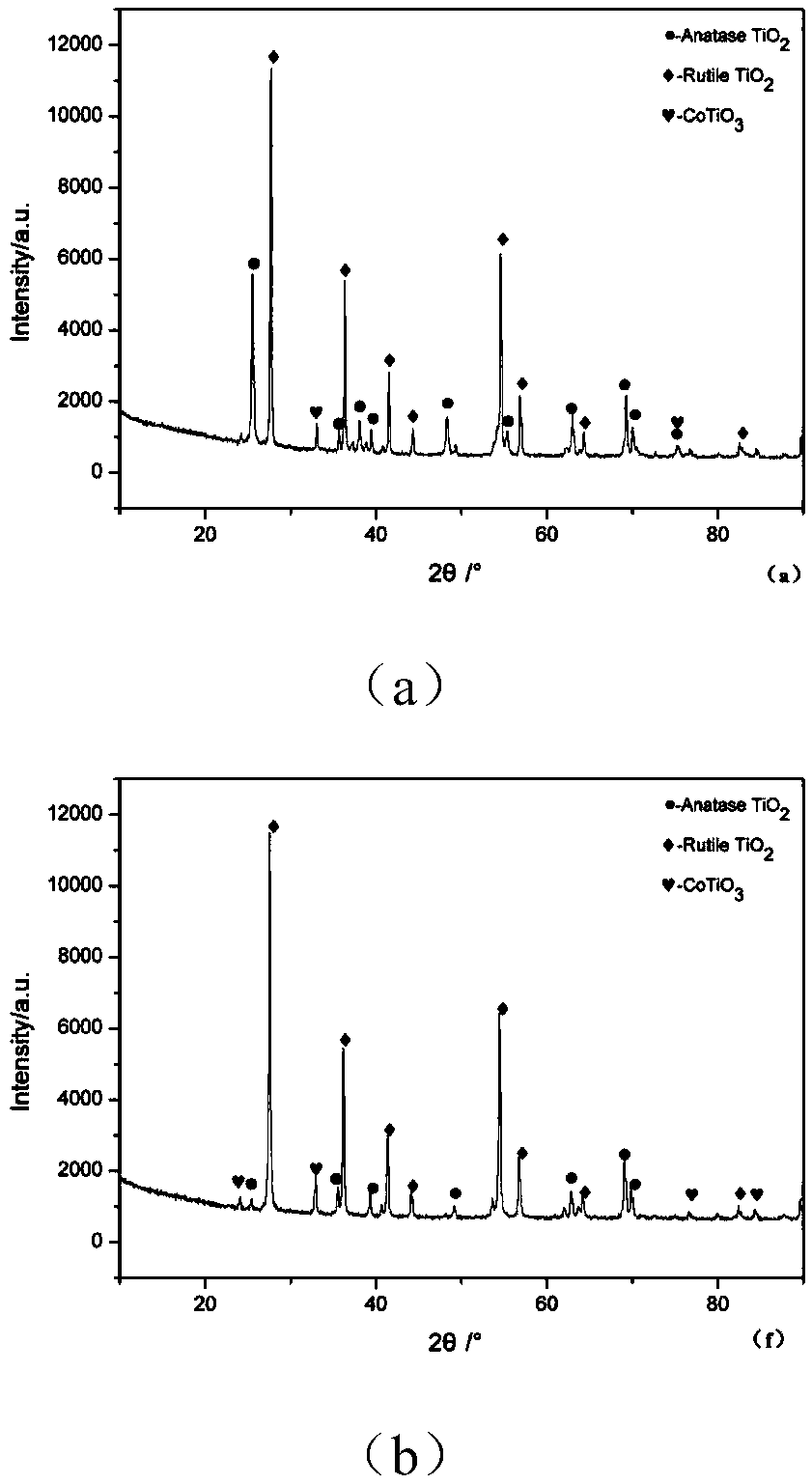

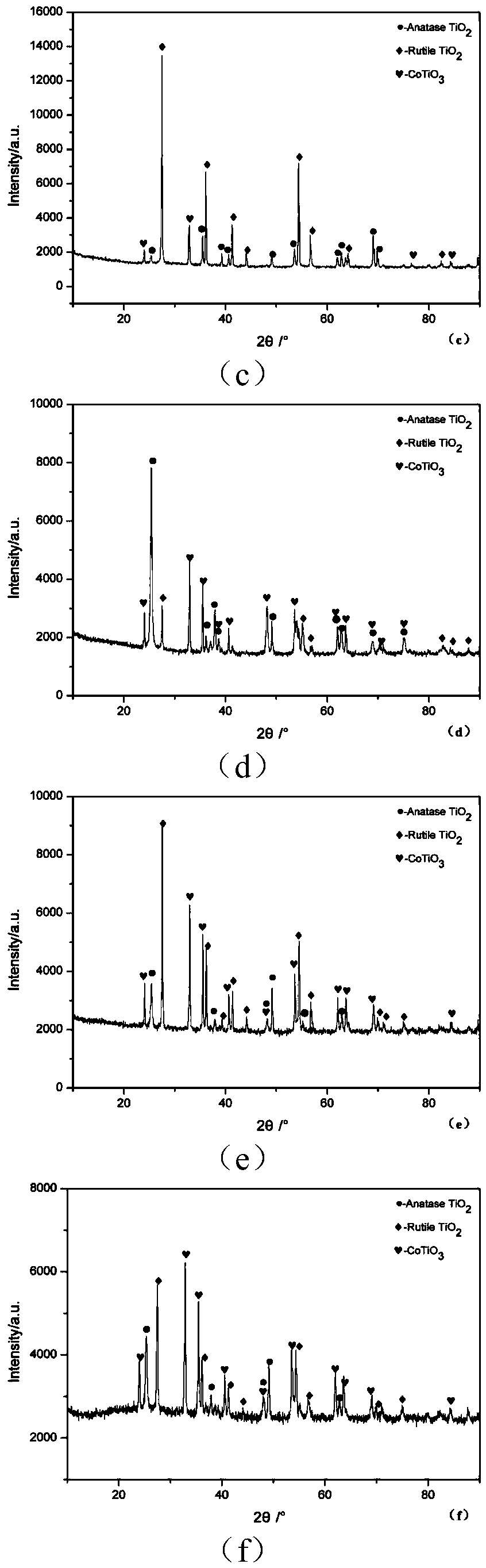

[0081] In conjunction with Examples 1-6, XRD, UV-Vis-DRS, FT-IR and other tests were carried out on the nanomaterials of the cobalt-doped titania sol prepared in Examples 1-6, and the test results are as follows: Figure 2-4 shown. Cobalt-doped titania sol nanomaterials prepared by the sol-gel method in Examples 1-6 were tested for the antibacterial performance of Escherichia coli by the shaking flask method and the antibacterial ring method, and the test results are as follows Figure 5 , 6 shown.

[0082] combine Figure 2-6 , the specific analysis is as follows: figure 2 a-f show the XRD analysis patterns of cobalt-doped titania sol nanomaterials...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com