Preparation method of high-strength seawater corrosion resistant wear composite coating

A composite coating, corrosion and wear technology, applied in the direction of coating, metal material coating process, melt spraying, etc., can solve the problems of reliability, safety and service life of mechanical parts, achieve excellent comprehensive performance, improve The effect of bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The invention discloses a method for preparing a high-strength seawater corrosion-resistant and wear-resistant composite coating. By adding metal element Mo, the microhardness of the coating can be effectively improved, the friction coefficient and wear rate of the coating in seawater environment can be reduced, and the wear resistance of the coating can be significantly improved. Tribological performance, the composite coating exhibits excellent comprehensive performance; the specific steps are as follows:

[0033] S1, mixed powder

[0034] In terms of mass fraction, NiCrAlY is 85-95%, Mo is 5-15%, and the weighed powder is mixed evenly on a three-dimensional powder mixer;

[0035] S2. Surface grinding treatment of base sample

[0036] Grind the cut substrate sample on coarse sandpaper to remove oil stains on the surface of the substrate sample;

[0037] S3. Sand blasting treatment on the surface of the sample

[0038] Before spraying, sand blast the surface of the ...

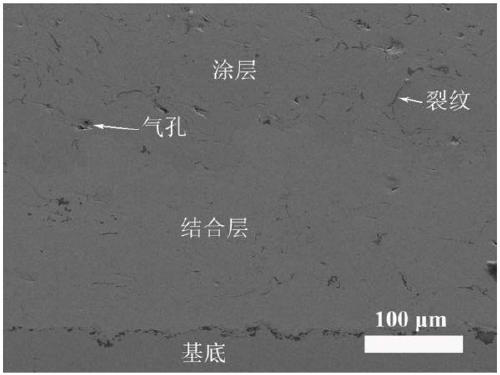

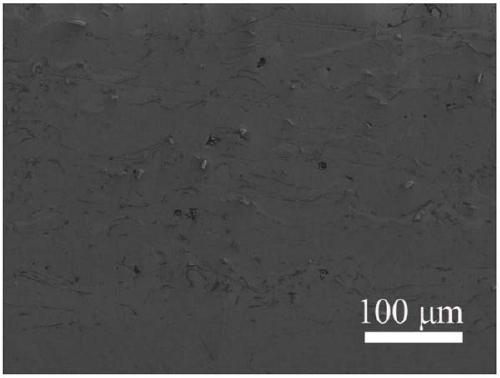

Embodiment 1

[0045] The spraying tests were carried out using the laboratory's SulZer Metco 9M plasma spraying apparatus. First, the uniformly mixed spray powder is dried in a vacuum drying oven to ensure smooth powder feeding during the spraying process, and then the base material is sandblasted and cleaned to remove residual oil stains and sand on the base surface. Before spraying, the substrate material should be preheated to reduce the temperature difference between the molten particles and the substrate surface, so that it can better adhere to the substrate surface, thereby improving the bonding strength of the coating. After the substrate sample is preheated to 300 At ~500°C, carry out the spraying test. The spraying parameters during the test are Ar flow rate 38-45L / min, H 2 The flow rate is 4.5-6L / min, the spraying angle is 80-100°, the powder feeding rate is 40-45g / min, the current is 500-550A, the voltage is 50-60V, and the spraying distance is 100-110mm. The composite coating ...

Embodiment 2

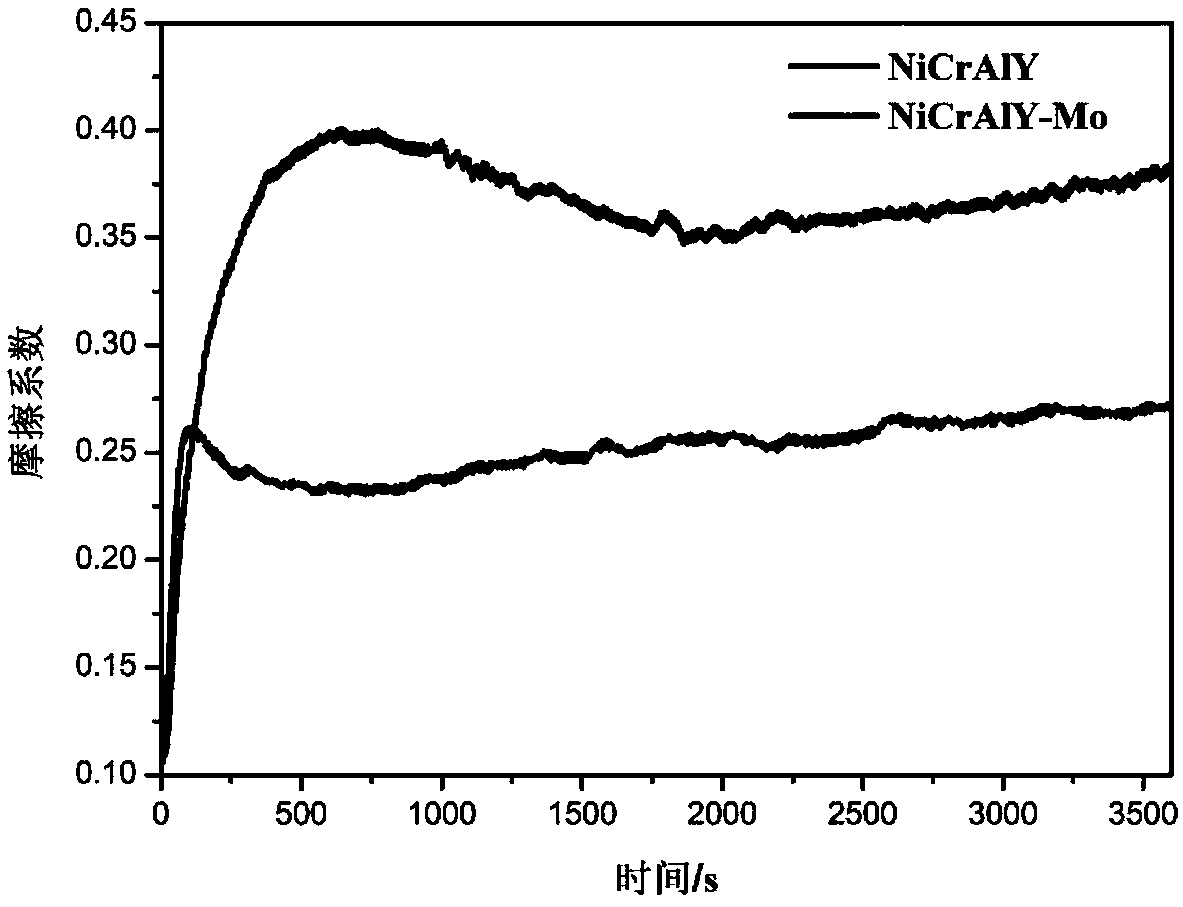

[0047] The coating prepared in Example 1 was cut into a corrosion wear test sample, the sample size was 20mm × 20mm × 1.5mm, the corrosion solution was artificial seawater, and the artificial seawater was proportioned according to the ASTMD114-98 standard, with 0.1M NaOH solution Adjust the pH value of the artificial seawater to 8.2. Before the test, the sample was soaked in the solution tank for 0.5 hours, and then the corrosion and wear test was carried out on the corrosion and wear testing machine. The friction speed is 0.8mm / s, the force is 5N, the reciprocating friction test range is 3.5mm, and the friction test is 1 hour. It is measured that after adding the metal element Mo, the friction coefficient of the coating is reduced from 0.36 to 0.25, and the wear rate is reduced from 4.6×10 -5 mm 3 / N.m reduced to 3.9×10 -5 mm 3 / N.m, the corrosion resistance and wear resistance are significantly enhanced, such as Figure 4 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com