Preparation method of nitrogen-silicon double-modified graphene quantum dot solid film

A graphene quantum dot, solid-state film technology, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve the problem of poor crystallinity of graphene quantum dots, difficulty in packaging, and low yield of graphene quantum dots, etc. problem, to achieve the effect of simple preparation method, overcoming difficulty in sealing and avoiding leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

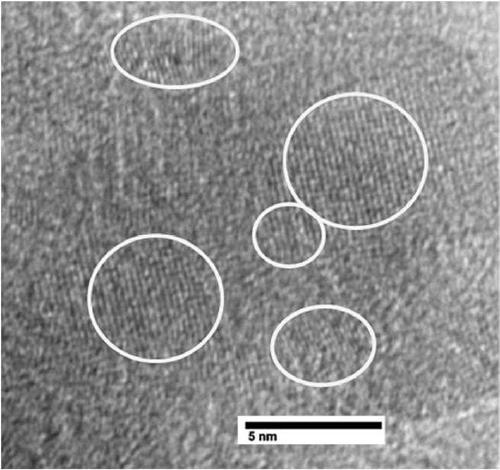

Image

Examples

Embodiment 1

[0013] A method for preparing a nitrogen-silicon double-modified graphene quantum dot solid film, the method comprising the following steps:

[0014] (1) Clean the monocrystalline silicon substrate with conventional cleaning methods;

[0015] (2) Using high-purity ethylene (purity greater than 99.995%), high-purity nitrogen (purity greater than 99.999%) and silane mixed gas diluted with argon to a concentration of 5% as the working gas, plasma enhanced chemical vapor deposition technology is used in the step (1) Deposit a layer of nitrogen-silicon double-modified graphene quantum dot solid film on the surface of the single crystal silicon substrate. The process parameters are: RF power density is 400W / cm 2 , the substrate temperature is 200°C, the RF frequency is 13.56MHz, the cavity pressure is 60Pa, the flow rate of high-purity ethylene gas is 60 sccm, the flow rate of high-purity nitrogen gas is 10 sccm, the flow rate of silane mixed gas is 5 sccm, and the coating time is 6...

Embodiment 2

[0018] A method for preparing a nitrogen-silicon double-modified graphene quantum dot solid film, the method comprising the following steps:

[0019] (1) Clean the monocrystalline silicon substrate with conventional cleaning methods;

[0020] (2) Using high-purity ethylene (purity greater than 99.995%), high-purity nitrogen (purity greater than 99.999%) and silane mixed gas diluted with argon to a concentration of 5% as the working gas, plasma enhanced chemical vapor deposition technology is used in the step (1) A layer of nitrogen-silicon double-modified graphene quantum dot solid film is deposited on the surface of the single crystal silicon substrate, and the process parameters are: the radio frequency power density is 500W / cm 2 , the substrate temperature is 250°C, the RF frequency is 13.56MHz, the cavity pressure is 80Pa, the flow rate of high-purity ethylene gas is 80 sccm, the flow rate of high-purity nitrogen gas is 12 sccm, the flow rate of silane mixed gas is 7 sccm,...

Embodiment 3

[0023] A method for preparing a nitrogen-silicon double-modified graphene quantum dot solid film, the method comprising the following steps:

[0024] (1) Clean the monocrystalline silicon substrate with conventional cleaning methods;

[0025] (2) Using high-purity ethylene (purity greater than 99.995%), high-purity nitrogen (purity greater than 99.999%) and silane mixed gas diluted with argon to 10% as the working gas, plasma enhanced chemical vapor deposition technology is used in the step (1) Deposit a layer of nitrogen-silicon double-modified graphene quantum dot solid film on the surface of the single crystal silicon substrate. The process parameters are: RF power density is 600W / cm 2 , the substrate temperature is 300°C, the RF frequency is 13.56MHz, the chamber pressure is 90Pa, the flow rate of high-purity ethylene gas is 90 sccm, the flow rate of high-purity nitrogen gas is 15 sccm, the flow rate of silane mixed gas is 10 sccm, and the coating time is 90 minutes.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com