Molybdenum-doped anatase titanium dioxide negative electrode material for lithium ion battery and preparing method of molybdenum-doped anatase titanium dioxide negative electrode material

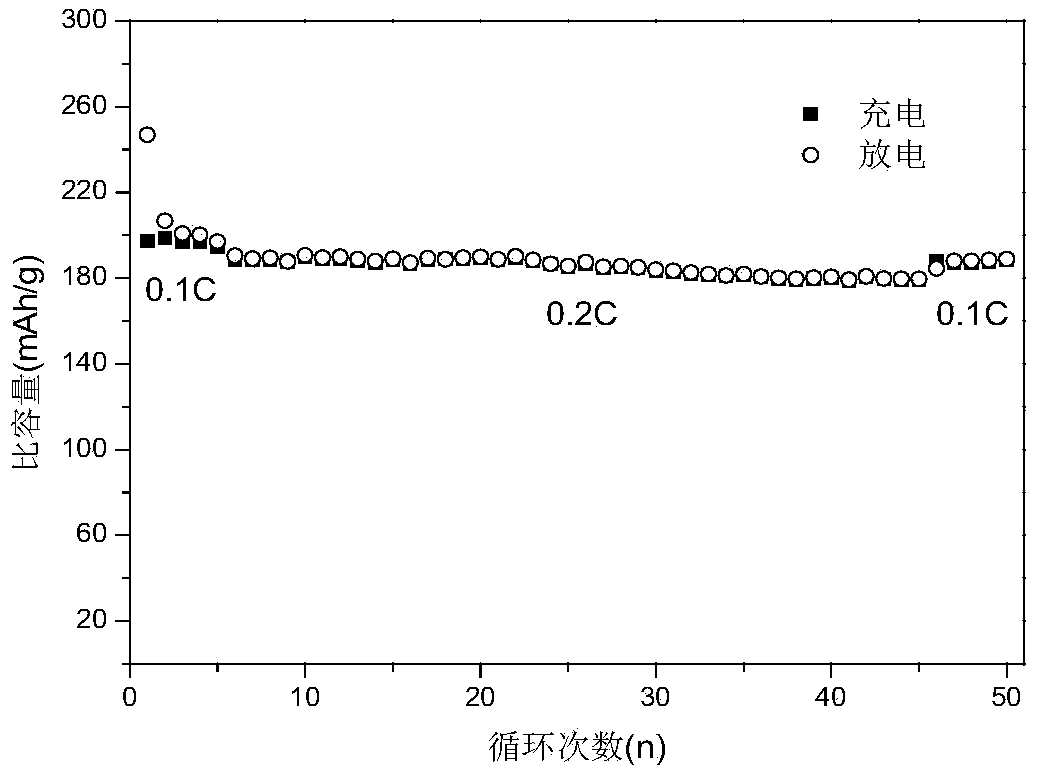

A lithium-ion battery, titanium dioxide technology, applied in the direction of battery electrodes, nanotechnology for materials and surface science, secondary batteries, etc., can solve the problems of low cycle capacity, low conductivity diffusion coefficient, etc., to achieve simple operation, Reversible capacity increase, environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

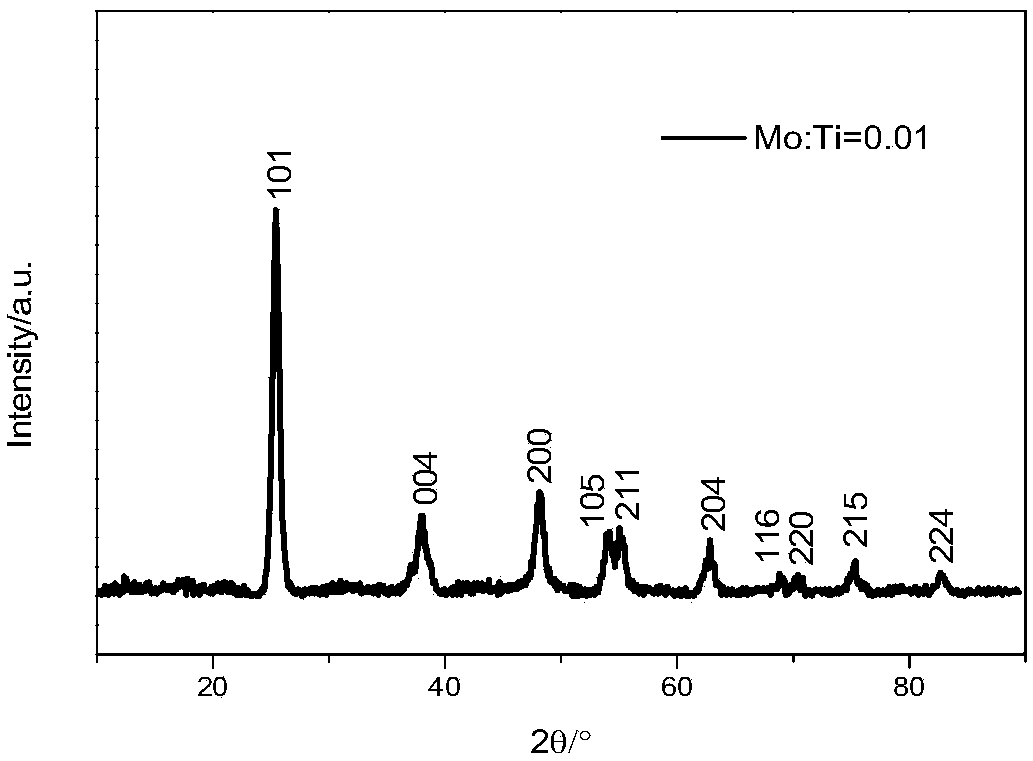

Embodiment 1

[0030] (1) First, measure 50 mL of absolute ethanol in a beaker, and add 10 mL of tetra-n-butyl titanate into it under magnetic stirring conditions to obtain solution 1;

[0031] (2) Weigh a certain amount of molybdenum source according to Mo:Ti=0.01 and dissolve it in 10mL deionized water to obtain solution 2;

[0032] (3) Pour solution 2 into solution 1 and keep stirring for 30 minutes;

[0033] (4) Then transfer the mixed solution obtained in (3) to a 100mL polytetrafluoroethylene-lined stainless steel hydrothermal reaction kettle, and place it in an oven for hydrothermal reaction at 120°C for 12 hours;

[0034] (5) After cooling to room temperature, the obtained product was centrifuged, washed with water, washed with alcohol and dried at 80°C for 12 hours;

[0035] (6) After grinding the product, place it in a muffle furnace and perform high-temperature calcination in an air atmosphere at a heating rate of 5°C / min under the conditions of 450°C and 4h. After cooling to ro...

Embodiment 2

[0037] (1) First, measure 40 mL of absolute ethanol in a beaker, and under magnetic stirring conditions, measure 10 mL of tetra-n-butyl titanate and add it to obtain solution 1;

[0038] (2) Weigh a certain amount of molybdenum source according to Mo:Ti=0.02 and dissolve it in 12mL deionized water to obtain solution 2;

[0039] (3) Pour solution 2 into solution 1 and keep stirring for 35 minutes;

[0040] (4) Then transfer the mixed solution obtained in (3) to a 100mL polytetrafluoroethylene-lined stainless steel hydrothermal reaction kettle, and place it in an oven for hydrothermal reaction under the conditions of 110°C and 10h;

[0041] (5) After cooling to room temperature, the obtained product was centrifuged, washed with water, washed with alcohol and dried at 70°C for 10 hours;

[0042] (6) After grinding the product, place it in a muffle furnace and perform high-temperature calcination in an air atmosphere at a heating rate of 5°C / min under the conditions of 450°C and ...

Embodiment 3

[0044] (1) First, measure 45 mL of absolute ethanol in a beaker, and add 10 mL of tetra-n-butyl titanate into it under magnetic stirring conditions to obtain solution 1;

[0045] (2) Weigh a certain amount of molybdenum source according to Mo:Ti=0.03 and dissolve it in 10mL deionized water to obtain solution 2;

[0046] (3) Pour solution 2 into solution 1 and keep stirring for 25 minutes;

[0047] (4) Then transfer the mixed solution obtained in (3) to a 100mL polytetrafluoroethylene-lined stainless steel hydrothermal reaction kettle, and place it in an oven for hydrothermal reaction under the conditions of 130°C and 14h;

[0048] (5) After cooling to room temperature, the obtained product was centrifuged, washed with water, washed with alcohol and dried at 90°C for 12 hours;

[0049] (6) After grinding the product, place it in a muffle furnace and perform high-temperature calcination in an air atmosphere at a heating rate of 3°C / min under the condition of 400°C for 5h. Afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com