Sheet material integrating filtering dust removal and catalytic denitration, and manufacturing method thereof

A technology for filtering dust and catalytic denitrification, applied to chemical instruments and methods, filtration separation, membrane filters, etc., can solve the problems of not being able to adapt to environmental protection policies, affecting production and operation, and occupying land, so as to facilitate popularization and application and prolong use Effect of life and reduction of manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

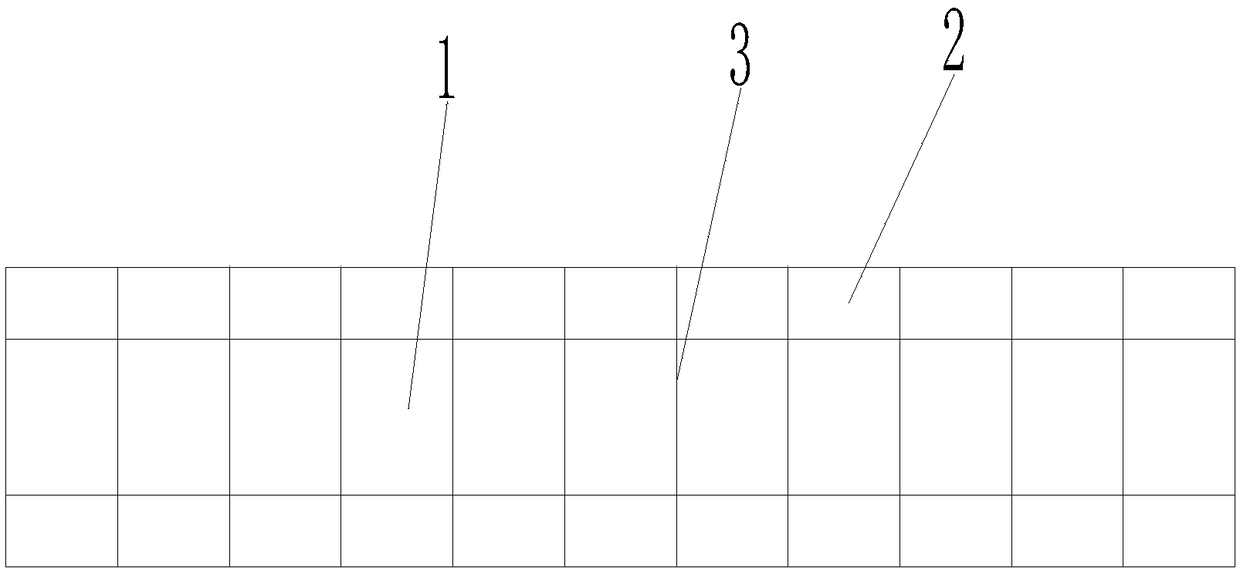

[0066] Such as figure 1 As shown, this embodiment provides a sheet material that integrates dust removal by filtration and catalytic denitrification, including a substrate 1 that can filter flue gas, and the substrate 1 that can filter flue gas is densely covered with dust filter ventilation holes 3. A catalyst 2 for denitrification is attached to the substrate 1 which can filter flue gas.

[0067] In this embodiment, since the base sheet capable of filtering flue gas is densely covered with dust filter ventilation holes, and the substrate capable of filtering flue gas is attached with a technical means for denitrification catalyst, the sheet material is put into the bag filter Inside, while filtering the soot in the industrial flue gas, it also performs catalytic denitration treatment on the industrial flue gas. Moreover, it avoids the problem of occupying land and requires less investment, which is conducive to the popularization and application of bag dust removal. The fla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com