Method for improving Beckmann rearrangement reaction catalyzing performance of shaped MFI molecular sieve

A Beckmann rearrangement and reaction performance technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc. The method is simple and the effect of improving the activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The extruded catalyst sample obtained in Comparative Example 1 was mixed with 25 wt% TPAOH solution at a mass ratio of 1:10, and crystallized at 170°C for 24 hours. After separation and washing, the solid was dried at 60°C and calcined at 450°C for 6 hours to prepare a gas-phase Beckmann rearrangement catalyst for caprolactam production.

Embodiment 2

[0031] The extruded catalyst sample obtained in Comparative Example 1 was mixed with 25 wt% TPAOH solution at a mass ratio of 1:10, and crystallized at 170°C for 48 hours. After separation and washing, the solid was dried at 60°C and calcined at 450°C for 6 hours to prepare a gas-phase Beckmann rearrangement catalyst for caprolactam production.

Embodiment 3

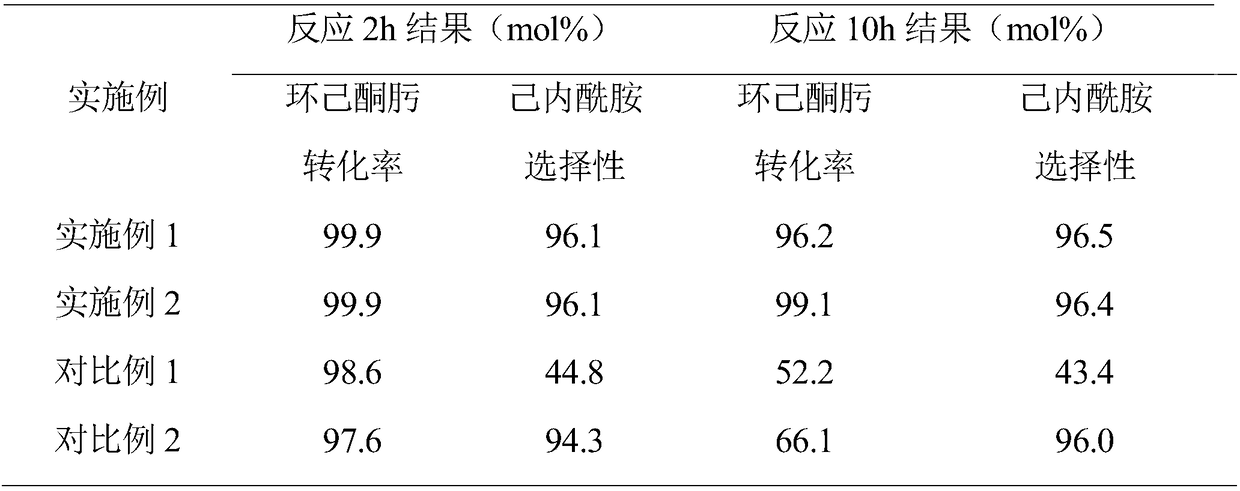

[0033] Examples 1, 2 and Comparative Examples 1, 2 Catalyst rearrangement reaction performance.

[0034] The gas-phase Beckmann rearrangement reaction of cyclohexanone oxime was carried out in a stainless steel fixed-bed reactor with an inner diameter of 6 mm. Crush the strip-shaped catalyst into 40-60mm size particles. Take 0.2000g of catalyst and load it into the reactor, and fill the top and bottom of the catalyst bed with 1.000g of 40-60 mesh quartz sand, and support it with quartz wool. In carrier gas N 2 With a flow rate of 20mL / min, the temperature was raised to 400°C at 13.3°C / min and kept for 1h, then the reaction temperature was lowered to 370°C, and the raw material was an ethanol solution (30wt%) of cyclohexanone oxime through a fixed bed by using an HPLC pressure pump. Reaction, the mass space velocity of cyclohexanone oxime is 8h -1 . Samples were collected every 2 hours using a gas-liquid separator cooled by an ice-water mixture, and each sample was taken fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com