Jun and Ru light greenish-blue glaze

A powder-green glaze and raw material technology, applied in the field of Junru powder-green glaze, can solve problems such as no research reports, and achieve the effects of pure glaze, delicate and soft enamel, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

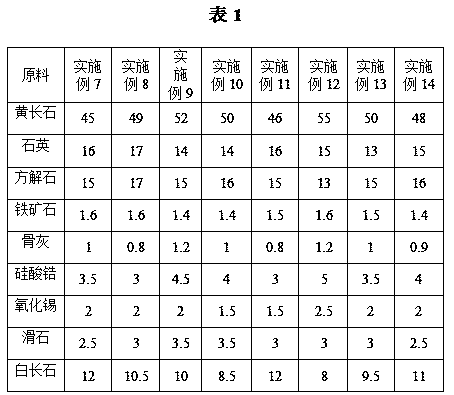

[0023] A Junru powder green glaze, which is prepared from the following raw materials in parts by weight: 45-55 feldspar, 13-17 quartz, 13-17 calcite, 1.4-1.6 iron ore, 0.8-1.2 bone ash, silicic acid Zirconium 3-5, tin oxide 1.5-2.5, talc 2.5-3.5, white feldspar 8-12.

[0024] In the formula, yellow feldspar and white feldspar are used as feldspar raw materials, and their metal content is different. They are mainly used as solvents, and the metal ions contained in them can also help color; The main raw material is mainly used for dissolution aid. Talc mainly provides magnesium ions, which can improve the glaze. The iron oxide content in iron ore is more than 70%, which is used to provide iron element for color development. In this formula, bone ash and zirconium silicate can significantly enhance the opacity effect of glaze. Tin oxide, as a chemical additive, contributes to the improvement of the color and the stability of the glaze quality. In the present invention, except...

Embodiment 2

[0034] A Junru powder green glaze, which is prepared from the following raw materials in parts by weight: 50 feldspar, 15 quartz, 15 calcite, 1.5 iron ore, 1 bone ash, 4 zirconium silicate, 2 tin oxide, 3 talc, albino 10.

[0035] The specific preparation method is as follows:

[0036] (1) Mix the above raw materials, ball mill, and pass through 250 sieves to obtain glaze slurry;

[0037] (2) Apply glaze on the biscuit fired carcass by dipping glaze, spraying glaze and other methods; the thickness of glaze is 0.7-1.0mm;

[0038] (3) Firing in an electric mixed firing kiln (such as the product provided by patent CN201510695873.3), which is specifically divided into the following stages:

[0039] ① Oxidation stage: adopt the electric firing method to raise the temperature from room temperature to 1000 ℃ at a constant speed within 6 hours;

[0040] ②Heavy reduction stage: adopt electric and gas mixed combustion method (on the basis of electric heating, liquefied petroleum gas ...

Embodiment 3

[0045] A Junru powder green glaze, which is prepared from the following raw materials in parts by weight: 54 feldspar, 17 quartz, 14 calcite, 1.4 iron ore, 0.9 bone ash, 4.5 zirconium silicate, 1.5 tin oxide, 2.5 talc, White feldspar9.

[0046] The specific preparation method is as follows:

[0047] (1) Mix the above raw materials, ball mill, and pass through 250 sieves to obtain glaze slurry;

[0048] (2) Apply glaze on the biscuit fired carcass by dipping glaze, spraying glaze and other methods; the thickness of glaze is 0.7-1.0mm;

[0049] (3) Firing in an electric mixed firing kiln (such as the product provided by patent CN201510695873.3), which is specifically divided into the following stages:

[0050] ① Oxidation stage: use electric firing method to rise from room temperature to 1000 ℃ at a constant speed in 6.5 hours;

[0051] ②Heavy reduction stage: adopt electric and gas mixed combustion method (on the basis of electric heating, liquefied petroleum gas is introduced...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com