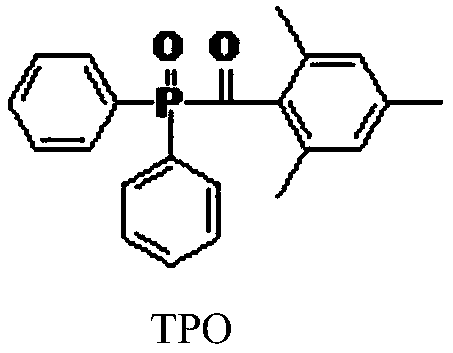

Preparation method of 2, 4, 6-trimethylbenzoyldiphenylphosphine oxide

A technology of trimethylbenzoyl diphenyl and diphenyl phosphine oxide, which is applied in the field of preparation of 2,4,6-trimethylbenzoyl diphenyl phosphine oxide, can solve the problem of difficult disposal of solid waste residue, Problems such as large safety hazards and few sources of raw materials achieve the effects of low cost, high environmental protection pressure, and difficult preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1: Preparation of 2,4,6-trimethylbenzoyl-diphenylphosphine oxide

[0026] (1) Under the protection of N2, take 120ml (1.35mol) of benzene, 40.0g (0.3mol) of aluminum trichloride, and 120ml (1.35mol) of phosphorus trichloride in a 500ml three-necked flask, stir well, and control the temperature at 70°C Left and right reflux reaction, after 4 hours of reaction, start to heat up and recover the solvent, raise the temperature to 200°C and continue the heat preservation reaction for 2 hours, after the heat preservation is completed, cool to room temperature, and slowly add the reaction solution dropwise to 300mL of 3% dilute hydrochloric acid in an ice bath to control the reaction The temperature does not exceed 20°C, react for 0.5h after dropping, add 100ml of benzene to extract, let it stand still, the water phase and the organic phase are clearly separated, both layers are transparent solutions, separate the organic phase, wash with water, remove the solvent to obt...

Embodiment 2

[0029] Embodiment 2: Preparation of 2,4,6-trimethylbenzoyl-diphenylphosphine oxide

[0030] (1) Under the protection of N2, take 60ml (0.67mol) of benzene, 90.0g (0.67mol) of aluminum trichloride, and 175ml (2.0mol) of phosphorus trichloride in a 500ml three-necked flask, stir well, and control the temperature at 70°C Left and right reflux reaction, after 4 hours of reaction, start to heat up and recover the solvent, raise the temperature to 200°C and continue the heat preservation reaction for 2 hours, after the heat preservation is completed, cool to room temperature, and slowly add the reaction solution dropwise to 300mL of 3% dilute hydrochloric acid in an ice bath to control the reaction The temperature does not exceed 20°C, react for 0.5h after dropping, add 100ml of benzene to extract, let it stand still, the water phase and the organic phase are clearly separated, both layers are transparent solutions, separate the organic phase, wash with water, remove the solvent to o...

Embodiment 3

[0033] Embodiment 3: Preparation of 2,4,6-trimethylbenzoyl-diphenylphosphine oxide

[0034] (1) The preparation process of diphenylphosphine oxide is the same as the (1) step in Example 1.

[0035] (2) Put 49.2g (0.3mol) of 2,4,6-trimethylbenzoic acid and 13.7g (0.1mol) of phosphorus trichloride in a 250ml three-necked flask, raise the temperature to 80°C and control the temperature for 5 hours, after the reaction is completed After standing for stratification, the phosphorous acid in the lower layer was separated, and the supernatant liquid was distilled under reduced pressure to obtain 47 g of refined 2,4,6-trimethylbenzoyl chloride, content: 99.0%, yield: 85.8%.

[0036] (3) The implementation steps are the same as those in Example 2 (3).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com