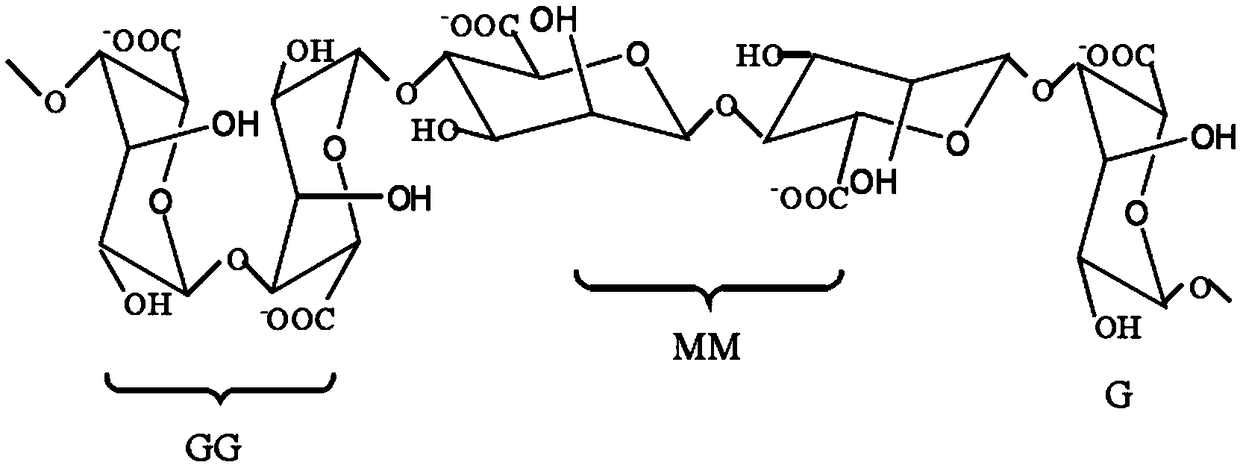

Uniform internal crosslinked sodium alginate film and preparation method thereof

A sodium alginate film and sodium alginate technology, applied in the field of uniform internal crosslinked sodium alginate film and its preparation, can solve the risk of gel unevenness, affecting gel film formation, gel film uncertainty, etc. problem, to achieve the effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

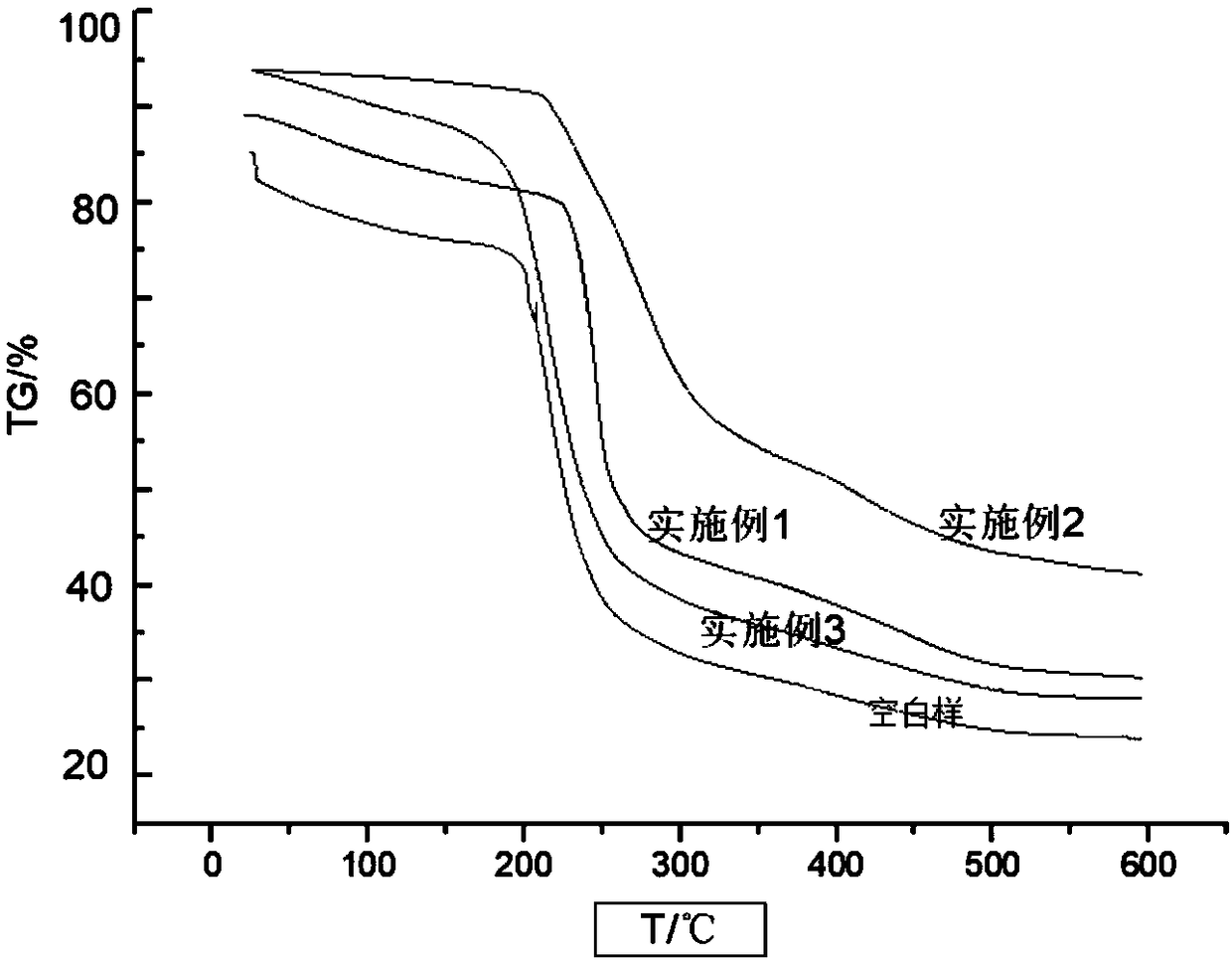

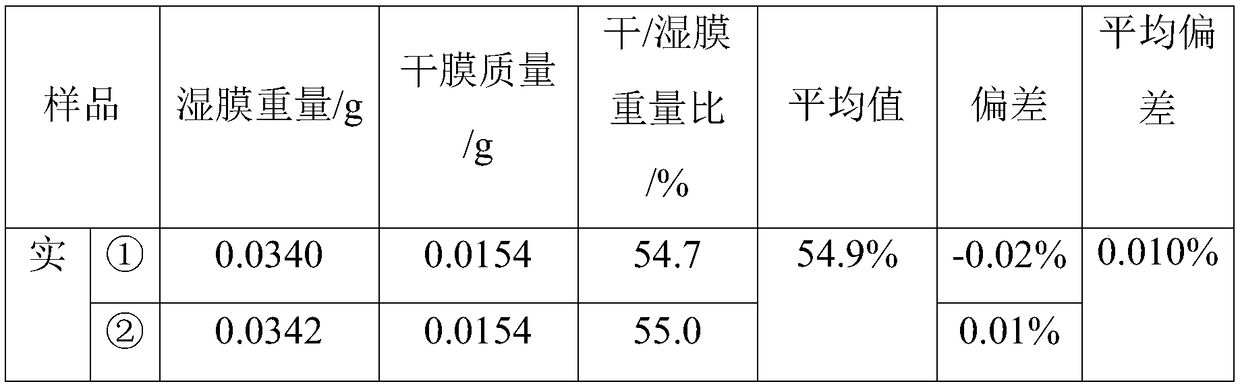

Examples

Embodiment 1

[0036] 1. Preparation of oligochitosan-calcium complex:

[0037] (1) Preparation of calcium salt concentrated solution

[0038] Dissolve 70g of anhydrous calcium chloride in 100mL of deionized water to prepare a calcium salt concentrated solution to obtain a 70% (m / v, g / 100mL) concentrated calcium chloride solution;

[0039] (2) Preparation of chitosan oligosaccharide-calcium complex

[0040] Take 0.3g chitosan oligosaccharide and add to 20mL above calcium chloride solution, add pH adjuster, adjust the pH value of the system between 9-10, and complex at room temperature for 30-45min;

[0041] (3) Alcohol precipitation of oligochitosan-calcium complex

[0042] Add 35 mL of absolute ethanol to the complexation system in (2), shake and mix well, and precipitate the chitosan oligosaccharide-calcium complex for 1-2 hours;

[0043] (4) Separation and purification of oligochitosan-calcium complex

[0044] (3) was centrifuged (8000rpm / 20min), the filter cake was washed with absolu...

Embodiment 2

[0054] This example is basically the same as Example 1, the difference is that in the step (3) of the preparation of the uniform internal crosslinked sodium alginate film, 0.2g chitosan oligosaccharide-calcium complex was dissolved in 10mL deionized water to prepare A 2% (w / v, g / 100mL) aqueous solution of the chitosan-calcium complex was obtained.

Embodiment 3

[0056] This example is basically the same as Example 1, the differences are: ①In the step (1) of the preparation of the uniform internal crosslinked sodium alginate film, add 5g of sodium alginate powder to 100mL of deionized water, and heat the system to 60 ℃, stirred to prepare 5% (m / v, g / 100mL) sodium alginate aqueous solution, cooled to room temperature; Dissolve the calcium complex in 10 mL of deionized water to prepare an aqueous solution of chitosan oligosaccharide-calcium complex with a concentration of 5% (w / v, g / 100 mL).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com