Plastic wood material

A plastic wood material and plastic technology, applied in the field of composite materials, can solve the problems of reduced performance, short service life, fracture, deformation, etc., and achieve the effects of enhanced strength, less wear, and good impact strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

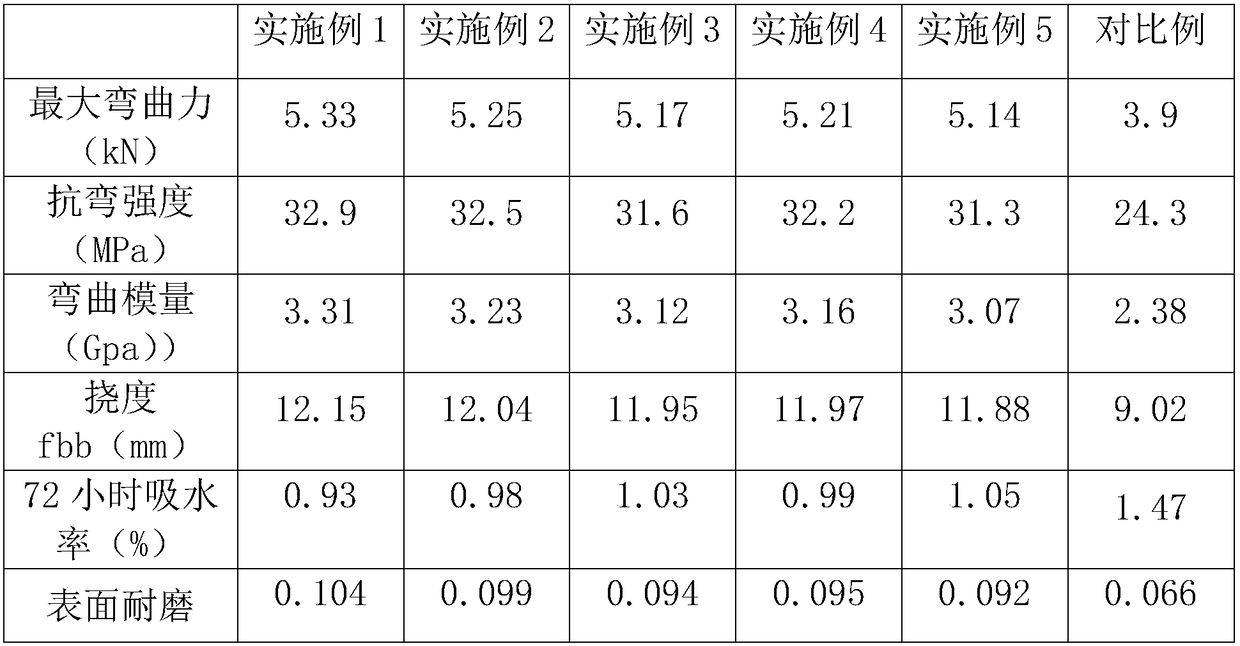

Examples

Embodiment 1

[0013] A wood-plastic material, the weight percentage of each component is: polyethylene particle 51.4%, wood powder 21.2%, hydroxymethylcellulose sodium 6.3%, copper acetate 3.6%, tea saponin 1.8%, talcum powder 3.7%, Color powder 0.95%, zinc stearate 1.05%, diphenylmethane diisocyanate 1.9%, manganese chloride 0.6%, borax 0.4%, plastic wood recycled material 7.1%.

[0014] The plastic wood material is prepared by the following method:

[0015] (1) Preparation of premix: Add wood powder into the high mixer, stir at a high speed of 1500-2500 rpm for 5 minutes, control the humidity of wood powder below 0.5%, then add other components respectively, and mix the above The mixed material is unloaded from the hot mixing system of the mixer to the cold mixing system, and cooled to 40°C to obtain the premixed material;

[0016] (2) Preparation of semi-finished granulated pellets: the premixed material is extruded and pelletized through a parallel twin-screw extruder, and the process ...

Embodiment 2

[0019] A wood-plastic material, the weight percentage of each component is: polypropylene particle 54.5%, wood powder 24.1%, hydroxymethyl cellulose sodium 7.1%, copper acetate 3.9%, tea saponin 1.7%, talcum powder 3.9%, Color powder 0.95%, calcium stearate 1.05%, toluene diisocyanate 1.8%, manganese carbonate 0.6%, borax 0.4%.

[0020] The plastic wood material is prepared by the following method:

[0021] (1) Preparation of premix: Add wood powder into the high mixer, stir at a high speed of 1500-2500 rpm for 5 minutes, control the humidity of wood powder below 0.5%, then add other components respectively, and mix the above The mixed material is unloaded from the hot mixing system of the mixer to the cold mixing system, and cooled to 40°C to obtain the premixed material;

[0022] (2) Preparation of semi-finished granulated pellets: the premixed material is extruded and pelletized through a parallel twin-screw extruder, and the process temperature is set at 180-200°C, waitin...

Embodiment 3

[0025] A kind of plastic wood material, the percentage by weight of each component is: polyethylene particle 46.8%, wood powder 29.6%, sodium hydroxymethyl cellulose 9.7%, copper acetate 2.8%, tea saponin 1.9%, talcum powder 3.3%, Color powder 1.2%, zinc stearate 1.2%, toluene diisocyanate 2.2%, manganese carbonate 0.7%, borax 0.6%.

[0026] The plastic wood material is prepared by the following method:

[0027] (1) Preparation of premix: Add wood powder into the high mixer, stir at a high speed of 1500-2500 rpm for 5 minutes, control the humidity of wood powder below 0.5%, then add other components respectively, and mix the above The mixed material is unloaded from the hot mixing system of the mixer to the cold mixing system, and cooled to 40°C to obtain the premixed material;

[0028] (2) Preparation of semi-finished granulated pellets: the premixed material is extruded and pelletized through a parallel twin-screw extruder, and the process temperature is set at 180-200°C, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com