Bio-based high-efficiency flame-retardant paint with universality, preparation method and application thereof

A flame retardant coating, bio-based technology, applied in fire retardant coatings, flame retardant fibers, chitin polysaccharide coatings, etc., can solve the problems of performance gap, deterioration of polymer mechanical properties, narrow applicability, etc., and achieve excellent thermal stability. Performance and barrier properties, effects of excellent thermal stability and barrier properties, good adhesion and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

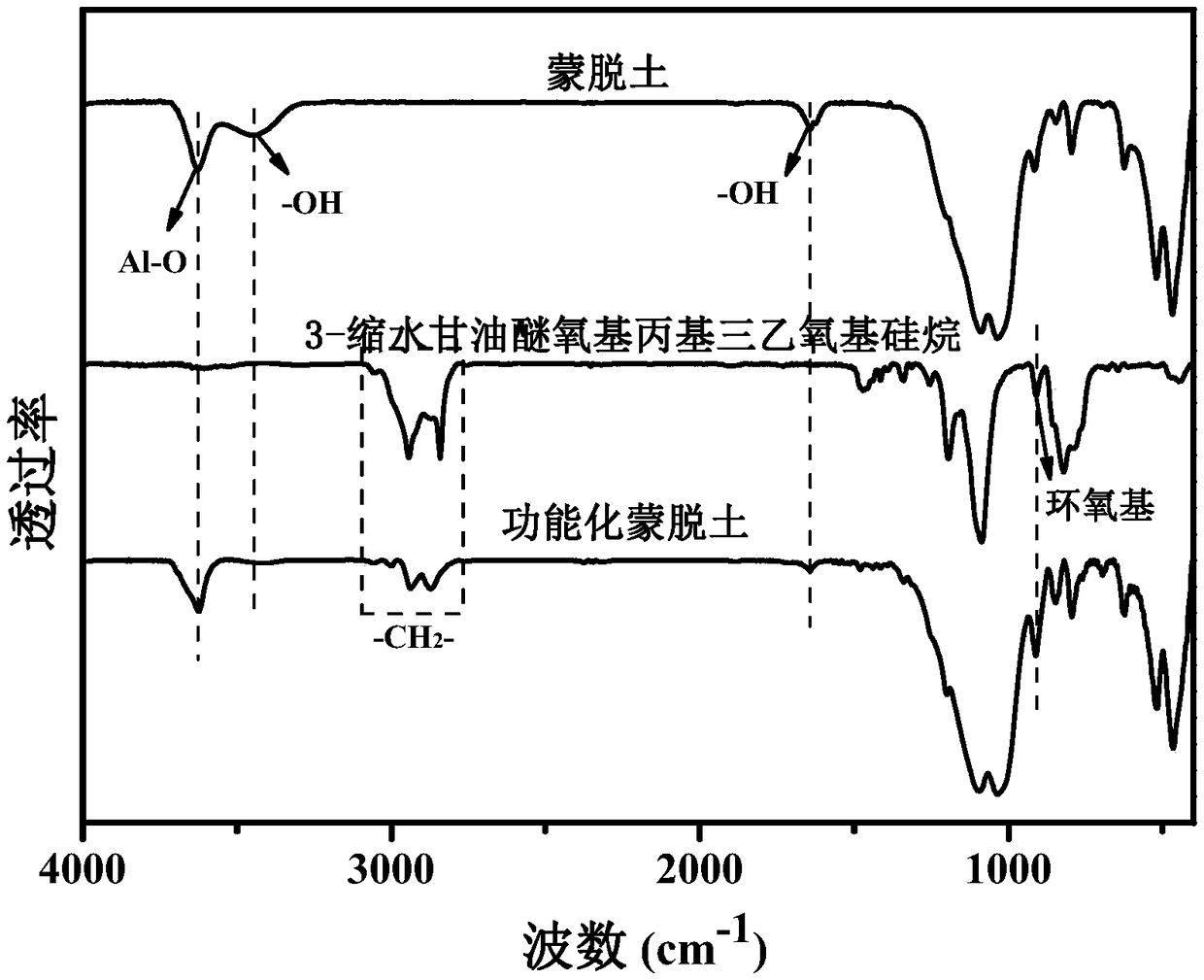

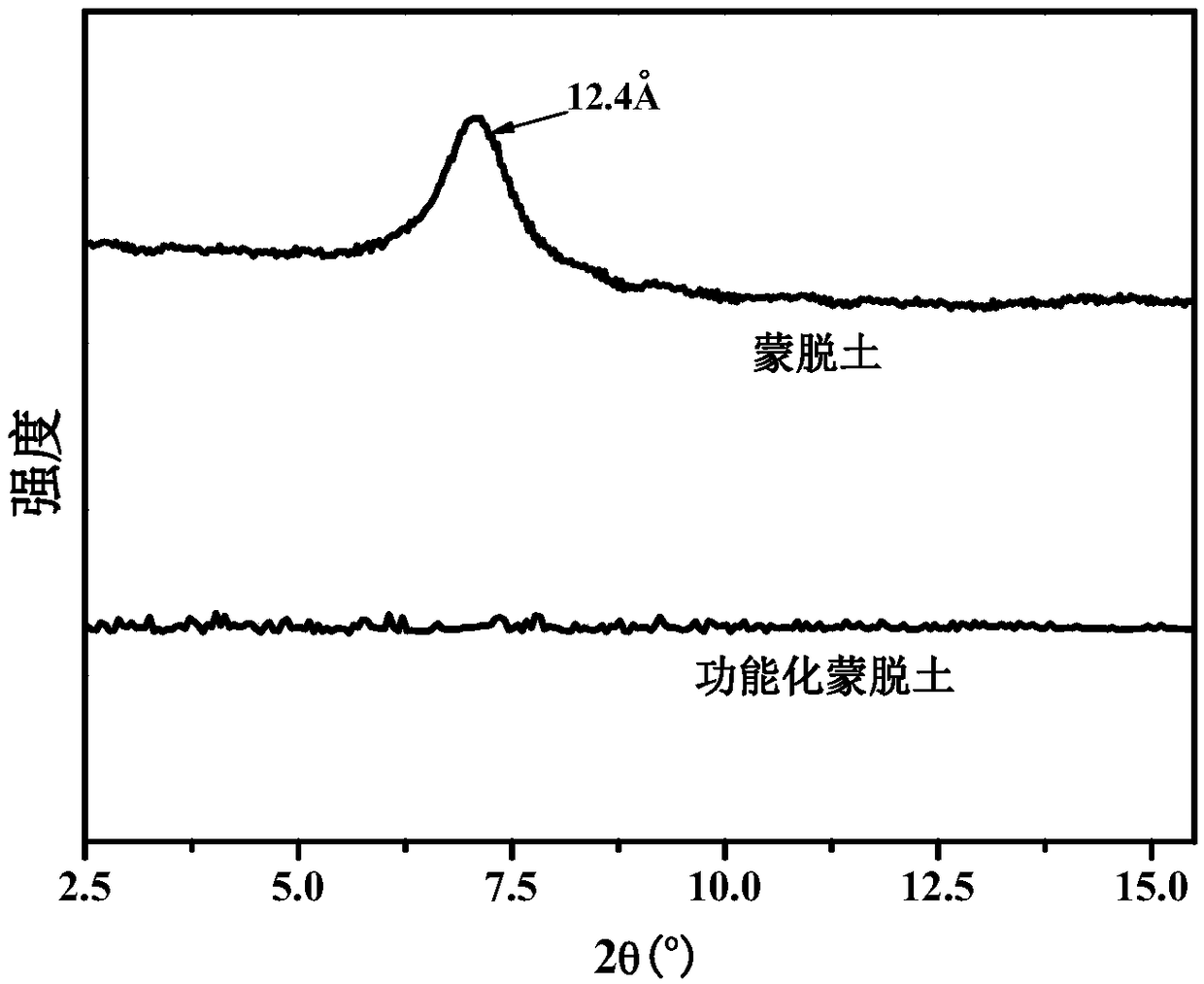

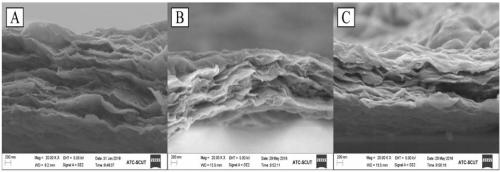

[0033] 1) Intercalation modification of layered nanomaterials: Add 300mL deionized water and 3.00g (about 2.3mmol) montmorillonite into a 500mL four-necked flask at 3‐5°C, and stir ultrasonically for 30min to make the montmorillonite Fully disperse the soil; dissolve 0.91g (2.5mmol) cetyltrimethylammonium bromide in 50mL deionized water, add it dropwise into the reactor within 0.5h under ultrasonic stirring, continue ultrasonic stirring for 2h, and then Stop ultrasonication and continue stirring for 12 hours; prepare 10 mL of hydrochloric acid solution with a concentration of 1 mol / L, add it dropwise into a four-necked flask within 20 minutes under ultrasonic stirring, and continue ultrasonic stirring for 1 hour; centrifuge the mixed solution after the reaction, and the precipitate Wash twice with deionized water and propanol, and then disperse in 300mL propanol by ultrasonic stirring to form a suspension;

[0034] 2) Synthesis of functionalized layered nanomaterials: Add step...

Embodiment 2

[0042] The difference between this example and Example 1 is that in step 1), 3.00g (about 2.3mmol) montmorillonite is replaced by 3g (11.6mmol) kaolin, and the amount of intercalation agent is changed to 4.37g (12.0mmol), adding After the intercalation agent, the ultrasonic stirring time was extended to 3h, and the continuous stirring time was extended to 16h after the ultrasonic was stopped. The amount of hydrochloric acid solution was changed to 20mL. In step 2), the amount of silane coupling agent was changed to 3.22g (11.6mmol). In step 3), 2.00 g of functionalized montmorillonite is replaced by 2.00 g of functionalized kaolin. The flame retardant performance test results are shown in Table 1, the test results of the coating stability and water resistance are shown in Table 2, and the relevant test methods are the same as in Example 1.

Embodiment 3

[0044] The difference between this example and example 1 is: in step 1), 3.00g (about 2.3mmol) montmorillonite is replaced by 3.00g (10.0mmol) zirconium phosphate, 0.91g (2.5mmol) hexadecyltrimethyl Ammonium bromide was replaced by 5.2g (20.0mmol) tetrabutylammonium hydroxide, the intercalation agent dropping time was extended to 1h, and the continuous stirring time was extended to 16h after the ultrasound was stopped. In step 2), the amount of silane coupling agent was changed to 2.78g (10.0mmol). In step 3), 2.00 g of functionalized montmorillonite was replaced with 2.00 g of functionalized zirconium phosphate. The flame retardant performance test results are shown in Table 1, the test results of the coating stability and water resistance are shown in Table 2, and the relevant test methods are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com