Preparation method and electrode of hydrophilic multilayer capacitive deionization electrode

A multi-layer structure and deionization technology, which is applied in the manufacture of hybrid capacitor electrodes, hybrid/electric double layer capacitors, etc., can solve the problems of reducing the theoretical adsorption/desorption performance of electrodes, achieve excellent conductivity, easy access to raw materials, and easy operation simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

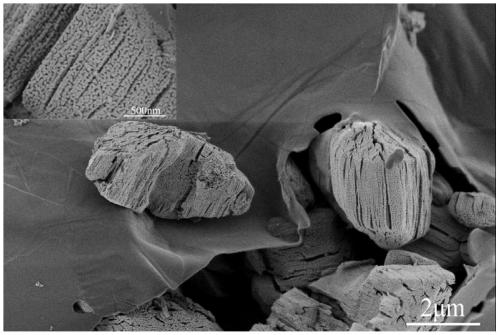

[0029] (1) Add 0.2mol oxalic acid and 100ml deionized water to ultrasonically disperse for 2 hours to obtain a uniform oxalic acid solution, then add 0.5mol graphene oxide to the oxalic acid solution and ultrasonically disperse for 3 hours to obtain a uniform graphene oxide oxalic acid solution; add 0.1mol zinc sulfate and 0.2mol ferrous sulfate plus 100ml deionized water for ultrasonic dispersion for 2 hours to obtain a zinc sulfate / ferrous sulfate mixture; put the graphene oxide oxalic acid solution and zinc sulfate / ferrous sulfate mixture in a hydrothermal kettle at 120~250°C The reaction was carried out for about 2 hours; the mixed solution (reaction product) after the reaction was filtered and washed 5-10 times repeatedly, and the pH of the washing solution was measured until the pH of the washing solution was neutral for the last time. The drying temperature was 100°C. A graphene / zinc ferrite composite material is obtained.

[0030] (2) The graphene / zinc ferrite composit...

Embodiment 2

[0033] (1) Add 0.3mol oxalic acid and 100ml deionized water to ultrasonically disperse for 2 hours to obtain a uniform oxalic acid solution, then add 1mol graphene oxide to the oxalic acid solution and ultrasonically disperse for 3 hours to obtain a uniform graphene oxide oxalic acid solution; mix 0.1mol zinc sulfate and Add 0.2mol of ferrous sulfate and 100ml of deionized water to ultrasonically disperse for 2 hours to obtain a mixture of zinc sulfate and ferrous sulfate; place the graphene oxide oxalic acid solution and zinc sulfate / ferrous sulfate mixture in a hydrothermal kettle for 2 hours at 200°C ; The mixed solution (reaction product) after the reaction is repeatedly sucked and washed to neutrality, and the graphene / zinc ferrite composite material is obtained after drying.

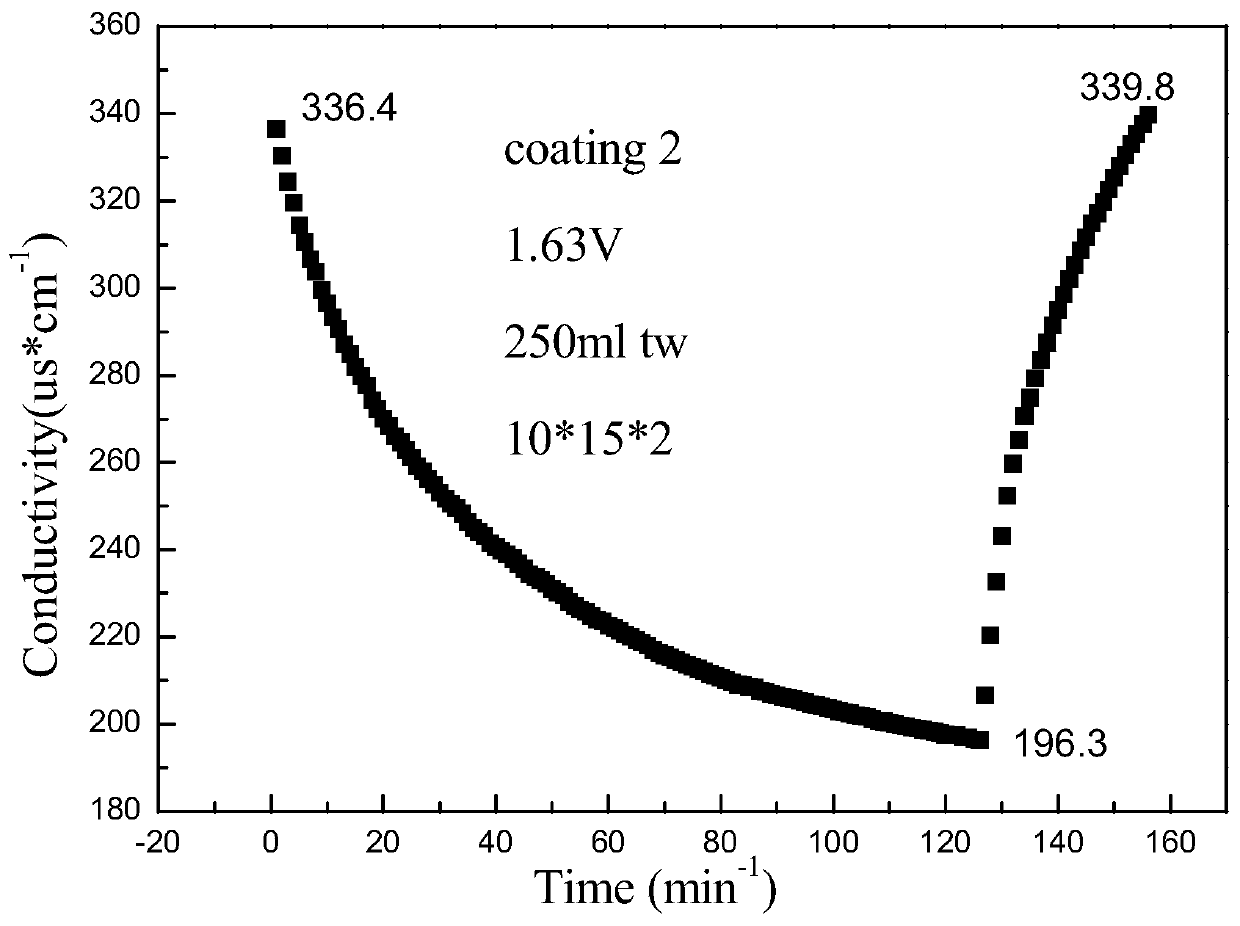

[0034] (2) The graphene / zinc ferrite composite material obtained in step (1) in this embodiment is mixed with 2.8g polyvinylidene fluoride plus 30ml nitrogen, nitrogen-dimethylacetamide solution to ...

Embodiment 3

[0037] (1) Ultrasonic disperse 0.5mol oxalic acid and 100ml deionized water for 2 hours to obtain a uniform oxalic acid solution, then add 3 mol graphene oxide to the oxalic acid solution and ultrasonically disperse for 3 hours to obtain a uniform graphene oxide oxalic acid solution; mix 0.1mol zinc sulfate and Add 0.2mol ferrous sulfate and 100ml deionized water to ultrasonically disperse for 2 hours to obtain a zinc sulfate / ferrous sulfate mixture; put the graphene oxide oxalic acid solution and the zinc sulfate / ferrous sulfate mixture in a hydrothermal kettle for reaction at 200°C 2h; the mixed solution (reaction product) after the reaction was repeatedly suction-filtered, washed until neutral, and dried to obtain a graphene / zinc ferrite composite material.

[0038] (2) Blend the graphene / zinc ferrite composite material obtained in step (1) of this example with 5g of polyvinylidene fluoride plus 30ml of nitrogen, nitrogen-dimethylacetamide solution to prepare electrode slurr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com