Preparation method of diatomite/molecular sieve composite material for adsorbing volatile organic pollutants

A technology of volatile organic and composite materials, applied in the direction of separation methods, chemical instruments and methods, silicate, etc., can solve the problems of unfavorable multi-component VOCs adsorption, increase the cost of pollutant treatment, and reduce the adsorption efficiency, etc., to achieve beneficial Effect of specific surface area and pore volume, increase of specific surface area and pore volume, and increase of loading rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

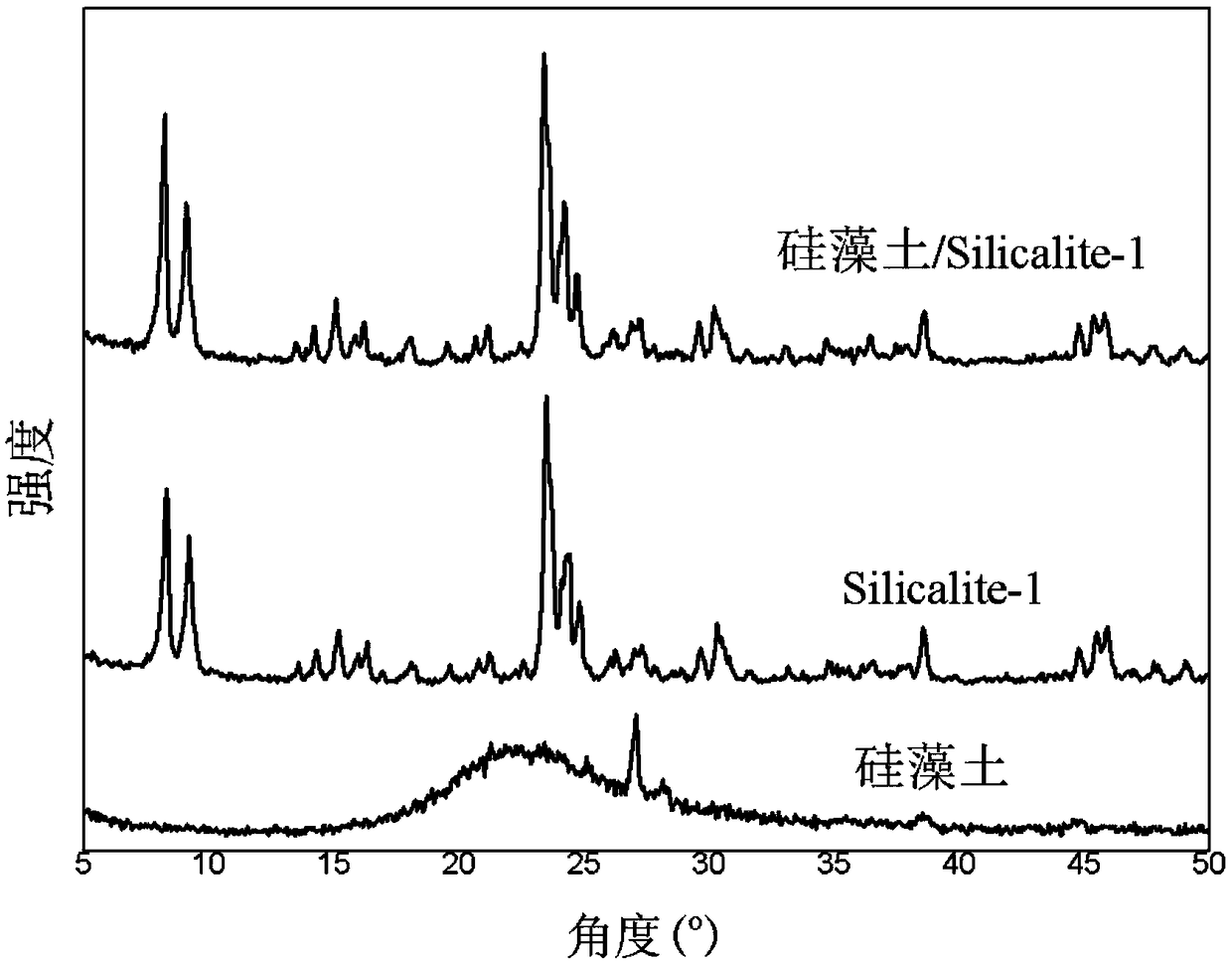

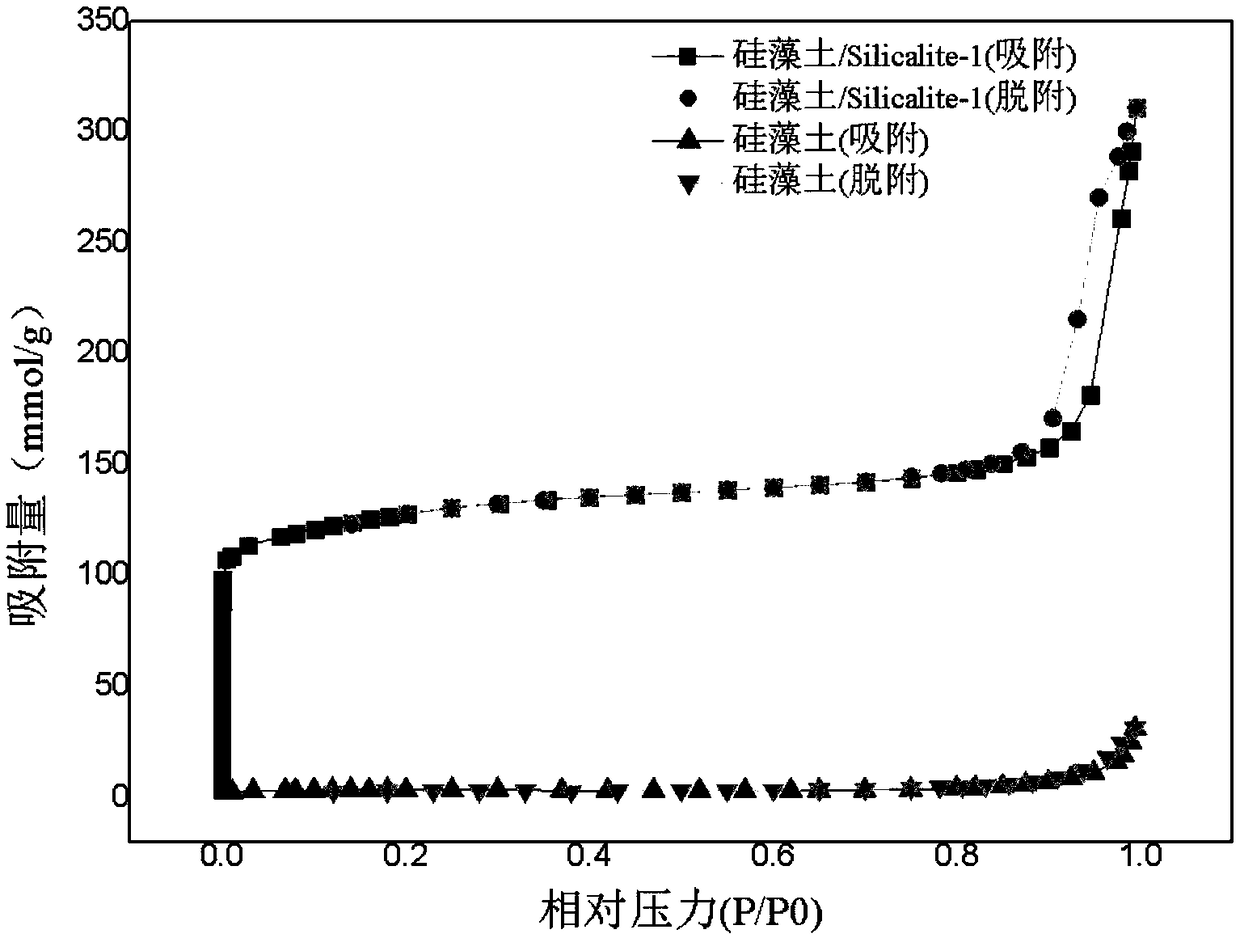

Embodiment 1

[0035] 1) Add 56ml of ethyl orthosilicate, 73ml of tetrapropylammonium hydroxide aqueous solution (25%) and 31ml of water into a beaker, stir for 12 hours, put it into a hydrothermal reactor, and set it at 100°C for 4 days. After the reaction was completed, the supernatant was removed by centrifugation, and distilled water was added to wash the remaining solid until the supernatant was neutral. After centrifugation, the solid was dried at 60°C. Then it was calcined in a muffle furnace at 550° C. for 6 hours in an air atmosphere to obtain a solid nano-Silicalite-1.

[0036]2) Add 5g of diatomaceous earth into 100ml of 6M hydrochloric acid solution, and stir in a water bath at 60°C for 4 hours. Afterwards, filter with suction, wash the solid with water until the supernatant is neutral, and dry at 60°C.

[0037] 3) Add the diatomite treated in step 2) into 100 ml of sodium hydroxide solution with pH=13.5, and stir in a water bath at 60° C. for 4 hours. Afterwards, filter with s...

Embodiment 2

[0044] 1) Add 56ml of ethyl orthosilicate, 73ml of tetrapropylammonium hydroxide aqueous solution (25%) and 31ml of water into a beaker, stir for 12 hours, put it into a hydrothermal reactor, and set it at 100°C for 4 days. After the reaction was completed, the supernatant was removed by centrifugation, and distilled water was added to wash the remaining solid until the supernatant was neutral. After centrifugation, the solid was dried at 60°C. Then it was calcined in a muffle furnace at 550° C. for 6 hours in an air atmosphere to obtain a solid nano-Silicalite-1.

[0045] 2) Add 5g of diatomaceous earth into 100ml of 6M hydrochloric acid solution, and stir in a water bath at 60°C for 4 hours. Afterwards, filter with suction, wash the solid with water until the supernatant is neutral, and dry at 60°C.

[0046] 3) Add the diatomite treated in step 2) into 100 ml of sodium hydroxide solution with pH=13.5, and stir in a water bath at 60° C. for 4 hours. Afterwards, filter with ...

Embodiment 3

[0053] 1) Add 56ml of ethyl orthosilicate, 73ml of tetrapropylammonium hydroxide aqueous solution (25%) and 31ml of water into a beaker, stir for 12 hours, put it into a hydrothermal reactor, and set it at 100°C for 4 days. After the reaction was completed, the supernatant was removed by centrifugation, and distilled water was added to wash the remaining solid until the supernatant was neutral. After centrifugation, the solid was dried at 60°C. Then it was calcined in a muffle furnace at 550° C. for 6 hours in an air atmosphere to obtain a solid nano-Silicalite-1.

[0054] 2) Add 5g of diatomaceous earth into 100ml of 6M hydrochloric acid solution, and stir in a water bath at 60°C for 4 hours. Afterwards, filter with suction, wash the solid with water until the supernatant is neutral, and dry at 60°C.

[0055] 3) Add the diatomite treated in step 2) into 100 ml of sodium hydroxide solution with pH=13.5, and stir in a water bath at 60° C. for 4 hours. Afterwards, filter with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com