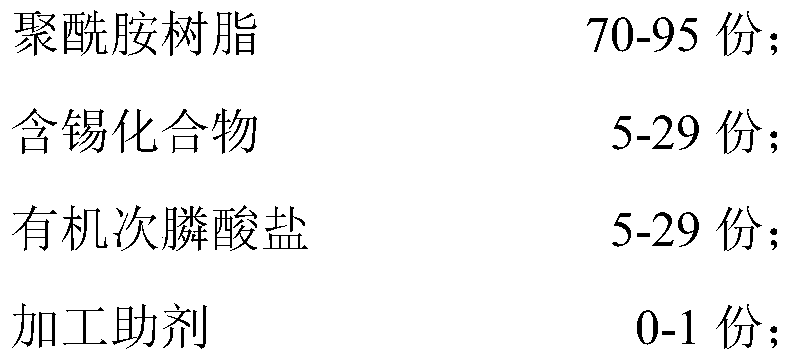

Flame retardant polyamide resin composition and preparation method thereof

A resin composition and technology of flame retardant polyamide, applied in the field of flame retardant polyamide resin, can solve problems such as poor flame retardant effect of halogen-free flame retardant, achieve excellent flame retardant effect, improve flame retardant effect, and good flame retardant effect effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0069] The preparation steps of complexes of the present invention are as follows:

[0070] (a) dissolving tin salt I or tin salt IV in X, where X is ethanol;

[0071] (b) Dissolving triphenylphosphine in Y and adding it to the system of step (a) and heating to 60-75°C for reflux for 2-6 hours, Y being ethanol;

[0072] (c) filtering, washing and drying to obtain the complex;

[0073] In parts by weight, the addition of each material is as follows:

[0074]

[0075] The present invention prepares triphenylphosphine tin protochloride complexes, triphenylphosphine tin chloride complexes, triphenylphosphine stannous cyanurate complexes and triphenylphosphine tin cyanurate complexes respectively by the above preparation method .

[0076] The preparation steps of the hybrid salt of the present invention are as follows:

[0077] (i) After dispersing A and tin salt I, tin salt II, tin salt III or the complex in solvent c, stir at a temperature of 40-90°C for 0.5-4 hours, solve...

Embodiment 1

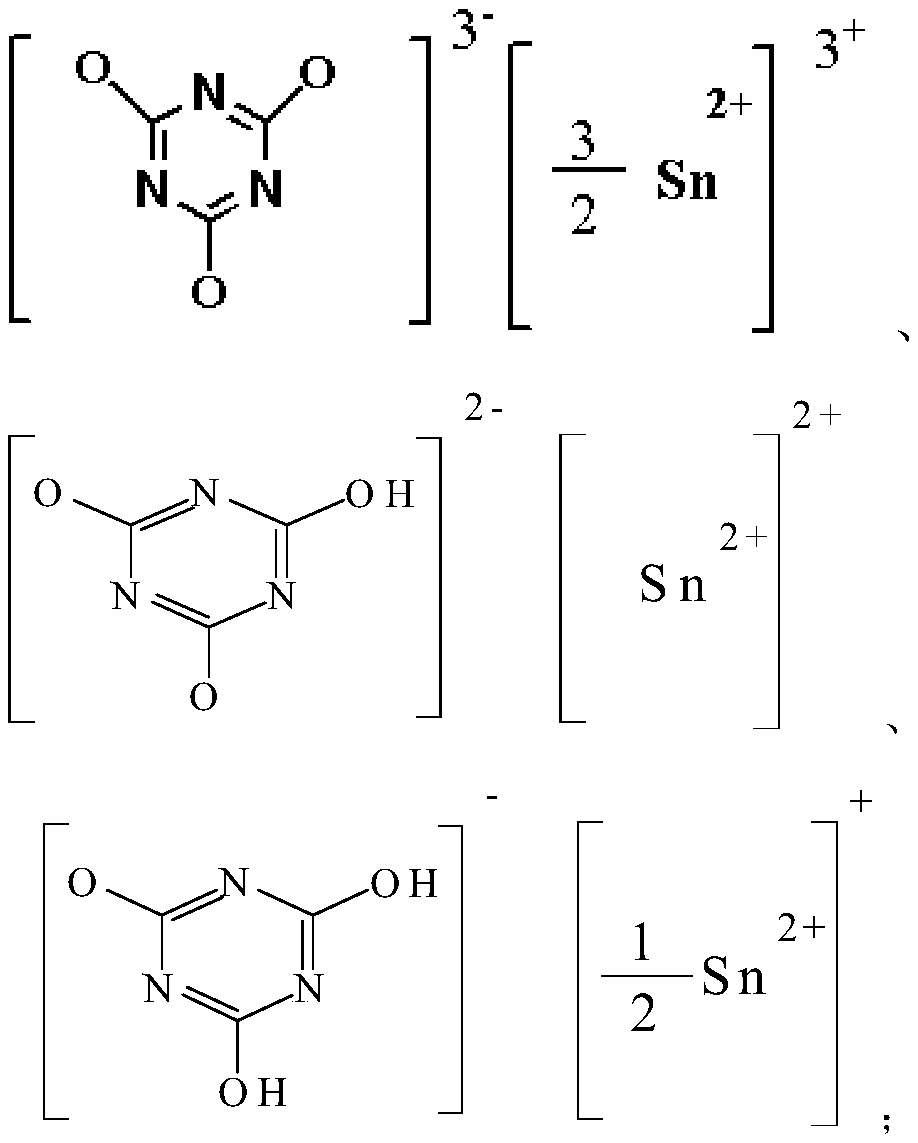

[0083] The preparation method of the flame-retardant polyamide resin composition, in parts by weight, 82 parts of nylon 6, 13 parts of stannous cyanurate, 22 parts of aluminum methyl phosphinate and 1 part of stearic acid are melted together Mix to obtain flame retardant polyamide resin composition, wherein, the temperature of melt blending is 220 ℃, after melt blending, cool with pure water, the structure of stannous cyanurate is:

[0084]

[0085] The flame retardant grade of the finally prepared flame retardant polyamide resin composition reaches UL94-V0, the limiting oxygen index is 40%, the GWIT is 880°C, and the GWFI is 960°C.

Embodiment 2

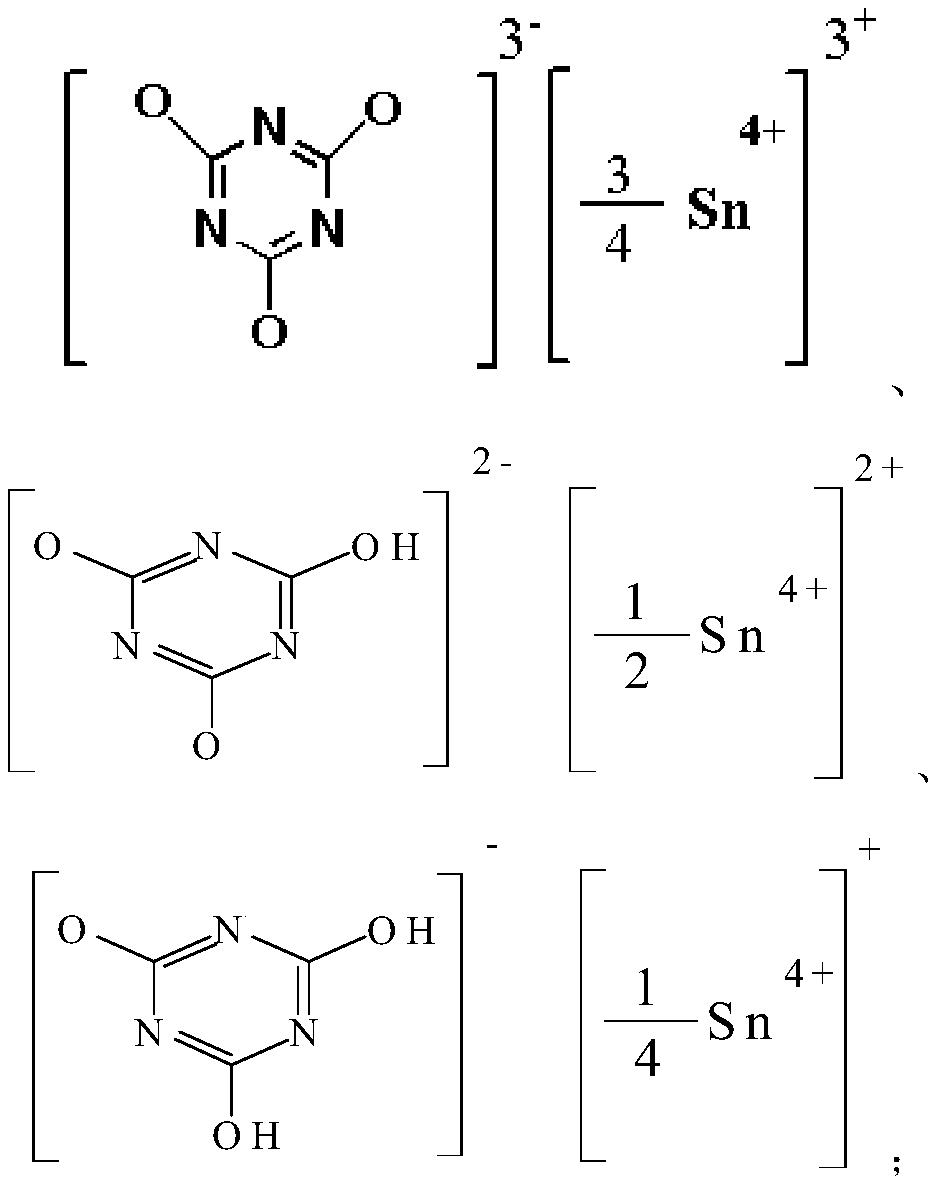

[0087] The preparation method of the flame-retardant polyamide resin composition is prepared by melting and blending 75 parts of nylon 12, 26 parts of stannous cyanurate and 6 parts of aluminum methyl phosphinate in parts by weight to obtain a flame-retardant polyamide The resin composition, wherein, the temperature of the melt-blending is 235° C., after the melt-blending, it is cooled with nitrogen with a purity ≥ 99.9%, and the structure of stannous cyanurate is:

[0088]

[0089] The flame retardant grade of the finally prepared flame retardant polyamide resin composition reaches UL94-V0, the limiting oxygen index is 40%, the GWIT is 850°C, and the GWFI is 960°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com