Preparation method of Bi2Te3/graphene composite thermoelectric material

A graphene composite and thermoelectric material technology, which is applied in the manufacture/processing of thermoelectric devices, thermoelectric device node lead-out materials, binary selenium/tellurium compounds, etc., to prevent a large number of stacking and agglomeration, high electrical conductivity, and improve dispersion performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

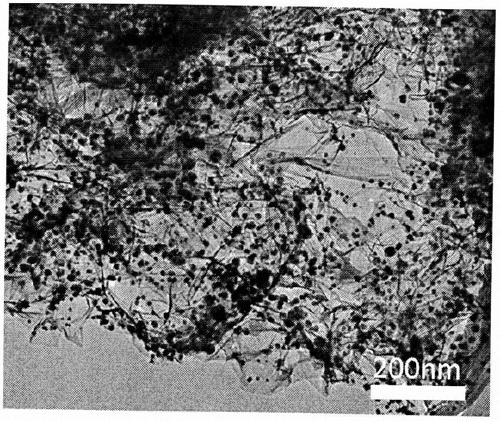

Image

Examples

Embodiment 1

[0025] (1) Add 200 mg of nano-graphene powder and 400 mg of sodium chlorate to 50 mL of concentrated sulfuric acid, and stir for 6 h in an ice bath.

[0026] (2) centrifugally cleaning the modified graphene, drying for use;

[0027] (3) 2 mmol Bi (NO 3 ) 3 Put the modified nano-graphene powder into 100 mL of distilled water and stir for 1 h.

[0028] (4) Add 3 mmol Na to the solution 2 TeO 3 , 10mmol NaBH 4 With 0.2g NaOH, the heating temperature is 60 ℃, and the time is 12h.

[0029] (5) The product was washed with water and ethanol, and dried under vacuum to obtain a black powder.

Embodiment 2

[0031] (1) Add 200 mg of nano-graphene powder and 800 mg of sodium chlorate to 50 mL of concentrated sulfuric acid, and stir for 3 h in an ice bath.

[0032] (2) centrifugally cleaning the modified graphene, drying for use;

[0033] (3) 2 mmol Bi (NO 3 ) 3 Put the modified nano-graphene powder into 100 mL of distilled water and stir for 1 h.

[0034] (4) Add 3 mmol Na to the solution 2 TeO 3 , 10mmol NaBH 4 With 0.2g NaOH, the heating temperature is 60 ℃, and the time is 12h.

[0035] (5) The product was washed with water and ethanol, and dried under vacuum to obtain a black powder.

Embodiment 3

[0037] (1) Add 200 mg of nano-graphene powder and 400 mg of sodium chlorate to 50 mL of concentrated sulfuric acid, and stir for 6 h in an ice bath.

[0038] (2) centrifugally cleaning the modified graphene, drying for use;

[0039](3) 2 mmol Bi (NO 3 ) 3 Put the modified nano-graphene powder into 100 mL of distilled water and stir for 4 h.

[0040] (4) Add 3 mmol Na to the solution 2 TeO 3 , 10mmol NaBH 4 With 0.2g NaOH, the heating temperature is 60 ℃, and the time is 12h.

[0041] (5) The product was washed with water and ethanol, and dried under vacuum to obtain a black powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com