Super-crosslinked polymer material and preparation method thereof

A polymer material and super-crosslinking technology, applied in separation methods, chemical instruments and methods, and other chemical processes, can solve the problems of polymer micropore rupture, unsatisfactory VOCs adsorption performance, and weak adsorption capacity, etc., to achieve increased Effects of large porosity, increased size, and increased adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

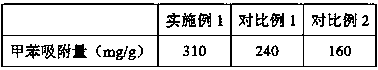

Embodiment 1

[0020] (1) Dissolve 0.15mol phenylethyl alcohol and 0.05mol dimethoxymethane into 15mL 1,2-dichloroethane, then add 0.15mol ferric chloride hexahydrate, stir at 50°C for 5h, then reflux at 80°C 24h, filter to obtain brown solid crude product;

[0021] (2) Ultrasonic disperse the brown solid crude product in absolute ethanol, and reflux for purification for 12 hours;

[0022] (3) After filtering the product obtained in step (2), ultrasonically disperse it in distilled water, and let it stand at 50°C for 6 hours;

[0023] (4) Filter the product prepared in step (3) and freeze-dry for 24 hours to obtain the hypercrosslinked polymer material HCP 1 .

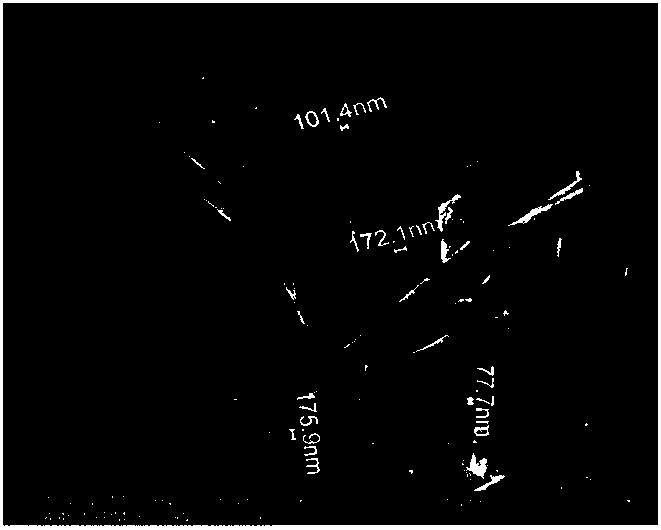

[0024] figure 1 Electron microscope image of the resulting hypercrosslinked polymer material. It can be seen from the figure that the prepared hypercrosslinked polymer is a uniform needle-like structure.

Embodiment 2

[0043] (1) Dissolve 0.05mol phenylethyl alcohol and 0.05mol dimethoxymethane into 13mL 1,2-dichloroethane, then add 0.05mol ferric chloride hexahydrate, stir at 50°C for 5h, then reflux at 60°C 25h, filter to obtain brown solid crude product;

[0044] (2) Ultrasonic disperse the brown solid crude product in absolute ethanol, and reflux for purification for 12 hours;

[0045] (3) After filtering the product obtained in step (2), ultrasonically disperse it in distilled water, and let it stand at 50°C for 6 hours;

[0046] (4) Filter the product prepared in step (3), and freeze-dry for 24 hours to obtain a hypercrosslinked polymer material.

Embodiment 3

[0048](1) Dissolve 0.1mol phenylethyl alcohol and 0.05mol dimethoxymethane into 20mL 1,2-dichloroethane, then add 0.1mol ferric chloride hexahydrate, stir at 50°C for 5h, then reflux at 120°C 15h, filter to obtain brown solid crude product;

[0049] (2) Ultrasonic disperse the brown solid crude product in absolute ethanol, and reflux for purification for 12 hours;

[0050] (3) After filtering the product obtained in step (2), ultrasonically disperse it in distilled water, and let it stand at 50°C for 6 hours;

[0051] (4) Filter the product prepared in step (3), and freeze-dry for 24 hours to obtain a hypercrosslinked polymer material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com