Method for treating industrial wastewater

A technology for industrial wastewater and treatment methods, applied in metallurgical wastewater treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of frequent and complicated system operation and maintenance, long electrode self-regeneration time, and large equipment footprint. Achieve the effect of being conducive to wide-scale promotion and application, eliminating the risk of chemical substances, and small footprint of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

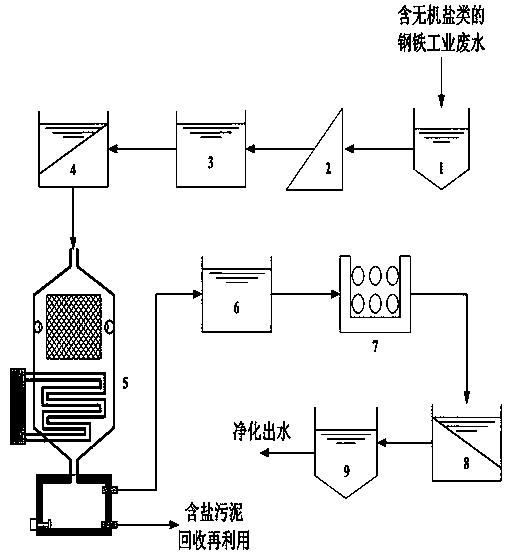

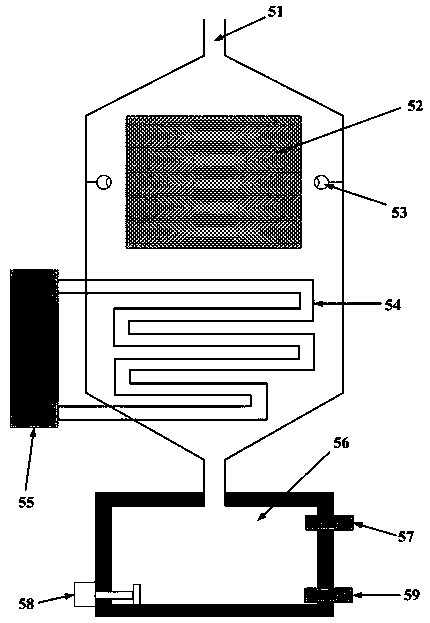

[0032] Such as figure 1As shown, the treatment method of inorganic salts in industrial wastewater, the iron and steel industrial wastewater containing inorganic salt ions enters the collection well 1 through the wastewater pipeline, where it is collected and initially stabilized, and the outlet of the collection well 1 is connected to the coarse grid through the wastewater pipeline Grid 2, where the large-diameter solid matter in the wastewater is removed, and the outlet of the coarse grid 2 is connected to the flocculation reaction tank 3 through the wastewater pipeline, where a chemical flocculant is added to the wastewater to make the suspended matter and macromolecular organic matter in the wastewater The flocculation reaction occurs, thereby converging into large groups of insoluble substances. The outlet of the flocculation reaction tank 3 is connected to the inclined plate sedimentation tank 4 through the waste water pipeline. The outlet of the pool 4 is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com