Preparation method for high-strength and high-porosity porous silicon nitride ceramics

A silicon nitride ceramic, high-porosity technology, applied in ceramic products, applications, household appliances, etc., can solve the problems of irregular pore structure and low strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

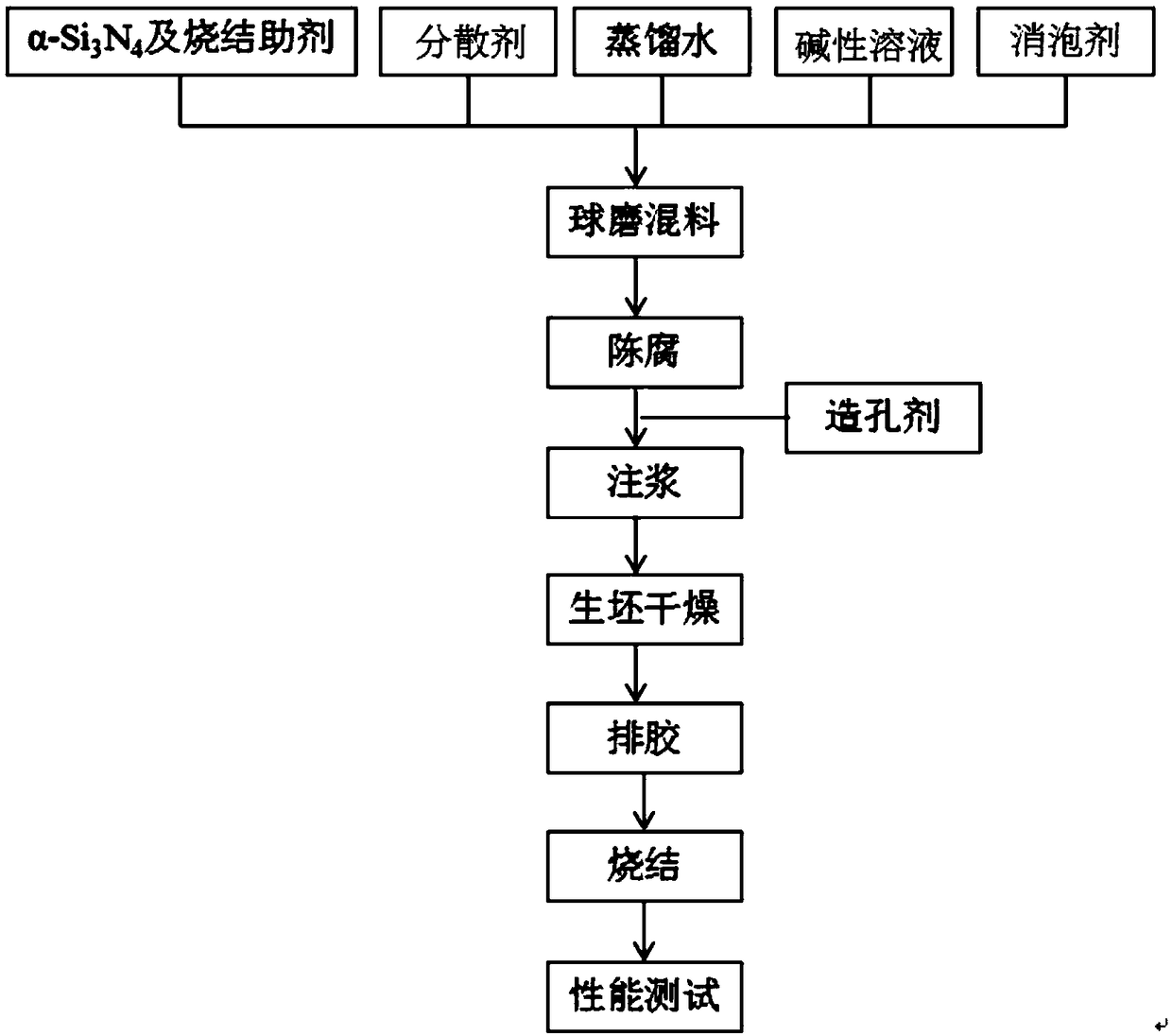

[0049] The invention discloses a method for preparing porous silicon nitride ceramics with high strength and high porosity, see figure 1 It is a specific flow chart of the preparation method of the invention, and the preparation method specifically includes the following steps:

[0050] Step 1, Prepare Water-Based Slurry

[0051] (1) Mixed α-Si 3 N 4 Raw material powder and rare earth oxide powder to obtain mixed powder A, rare earth oxide includes Y 2 o 3 , La 2 o 3 and Ce 2 o 3 etc.; in terms of mass percentage, the α-Si in mixed powder A 3 N 4 The proportion of raw material powder is 94%-97%, the proportion of rare earth oxide powder is 3-6%, and the sum of the two is 100%; the mixed powder A is placed in the ball mill tank;

[0052] (2) Weigh 0.1%-0.5% of the dispersant of mixed powder A mass, disperse the dispersant in deionized water at 50°C-70°C, and prepare a dispersant solution with a mass fraction of 0.5%-1.5%; Select any one of sodium carboxymethylcellulo...

Embodiment 1

[0084] Step 1, Prepare Water-Based Slurry

[0085] (1) Mixed α-Si 3 N 4 Raw material powder and Y 2 o 3 powder to obtain mixed powder A, in which α-Si 3 N 4 The mass ratio of raw material powder is 95%, Y 2 o 3 The proportion of powder is 5%, and the mixed powder A is placed in a ball mill jar;

[0086] (2) Weigh 0.3% CMC of the mass of the mixed powder A as a dispersant, disperse the CMC in 60° C. deionized water, prepare a CMC solution with a mass fraction of 1%, and add the dispersant aqueous solution to the ball mill tank;

[0087] (3) Adjust the pH value of deionized water to 10.5 with concentrated ammonia water to make an alkaline solution; add the alkaline solution with a pH value of 10.5 into the ball milling tank until the mass fraction of mixed powder A in the ball milling tank is 50 %, stir evenly to prepare slurry C;

[0088] (4) Add defoamer glycerol dropwise in slurry C, the addition of glycerol is 0.05% of the mass of mixed powder A, and water-based slu...

Embodiment 2

[0095] Adjust the amount of pore-forming agent added in step 2 in Example 1, specifically adding 40% soluble starch by volume of mixed powder A to stale slurry E, and the rest of the steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com