Anticorrosive paint for seawater pipeline and preparation method thereof

A technology for anti-corrosion coatings and pipes, applied in the field of coatings, can solve problems such as damage to the marine ecological environment, and achieve the effects of improving roughness, lasting utility and inhibiting microbial adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The preparation method of anticorrosion coating for seawater pipeline of the present invention:

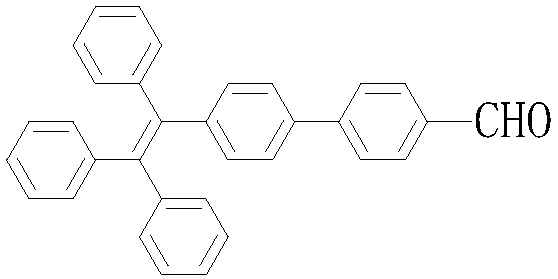

[0022] (1) Preparation of piezoluminescent material: Dissolve bromotetraphenylethylene and 4-formylphenylboronic acid in toluene, add tetrabutylammonium bromide and potassium carbonate aqueous solution; Phenylphosphine) palladium, heated to 90 ° C for 24 hours; after the reaction, the reaction solution cooled to room temperature was poured into water, and extracted with ethyl acetate; after the organic layer was dried with anhydrous sodium sulfate, the solvent was evaporated and used Silica gel column chromatography is purified, and the mixed solvent of n-hexane and methylene chloride is used as the eluent to leaching, and the white product obtained is the piezoluminescence material, and the output rate is 88%; because the coating of the present invention is generally used Natural light is relatively poor on seawater piping components. Therefore, in order to ensure the act...

Embodiment 1

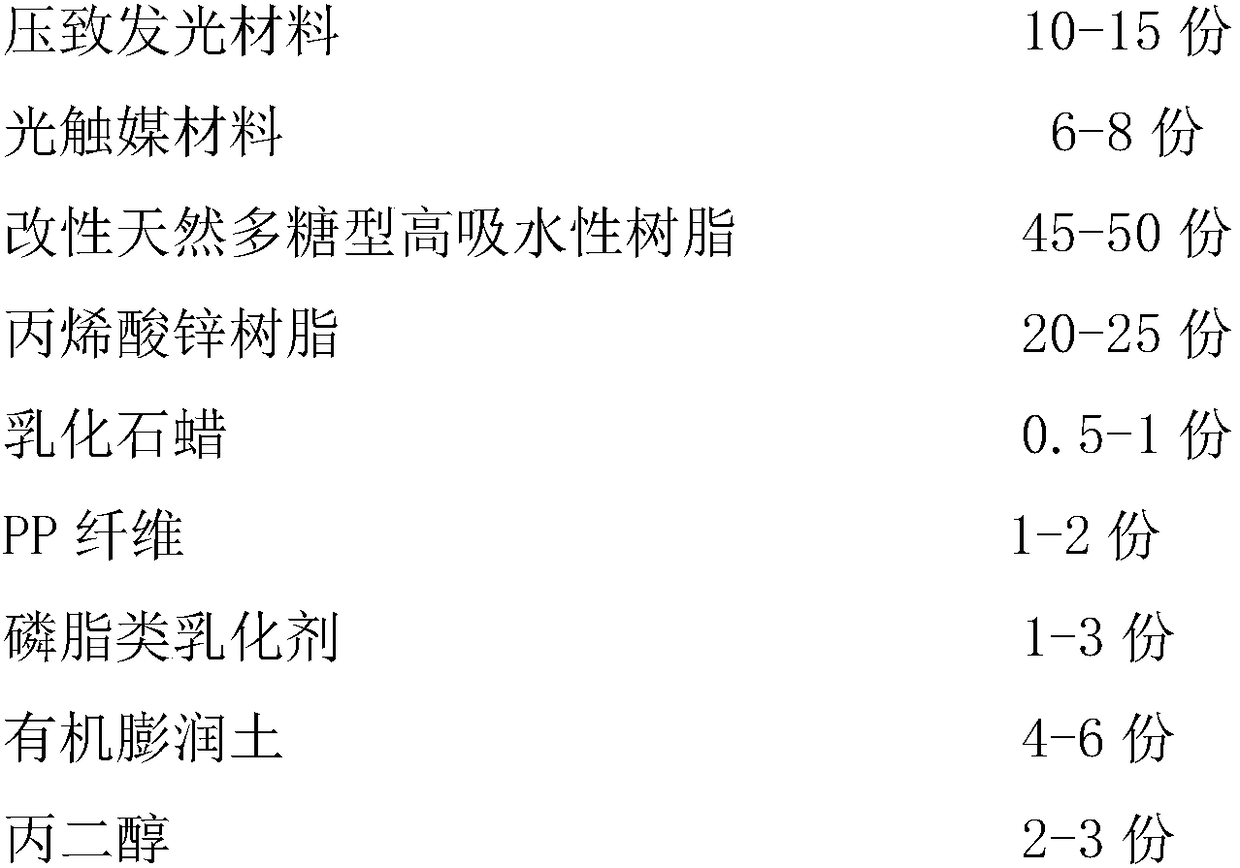

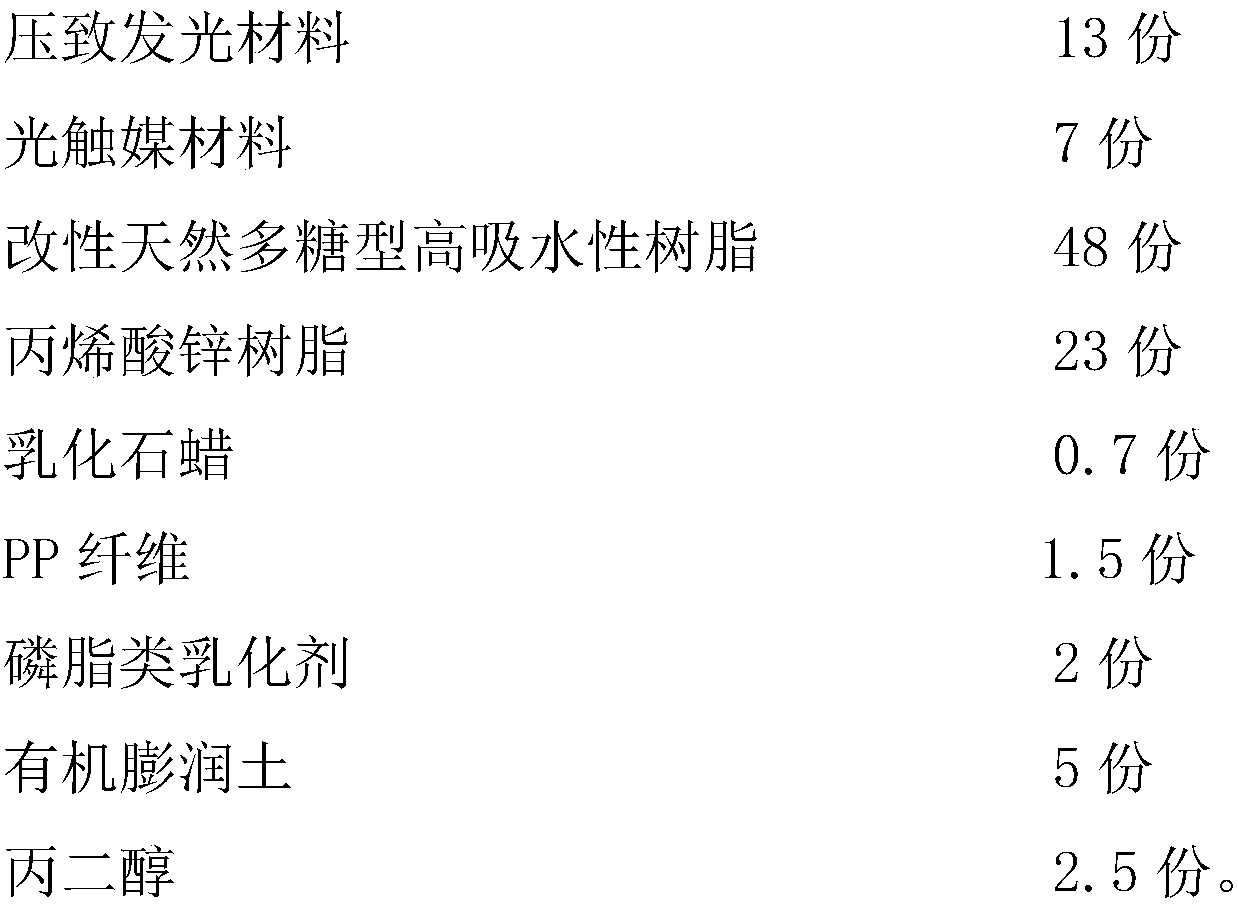

[0028] 10 parts of piezoluminescent material, 8 parts of photocatalyst material, 45 parts of modified natural polysaccharide superabsorbent resin, 25 parts of zinc acrylate resin, 0.5 part of emulsified paraffin, 2 parts of PP fiber, 1 part of phospholipid emulsifier, 6 parts of organic bentonite 2 parts, 2 parts of propylene glycol.

Embodiment 2

[0030] 15 parts of piezoluminescent material, 6 parts of photocatalyst material, 50 parts of modified natural polysaccharide superabsorbent resin, 20 parts of zinc acrylate resin, 1 part of emulsified paraffin, 1 part of PP fiber, 3 parts of phospholipid emulsifier, 4 parts of organic bentonite 3 parts, 3 parts of propylene glycol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com