A kind of graphene nano disk and its preparation method and application

A nanodisk and graphene technology, applied in the field of nanomaterials, can solve the problems of complex production process, high cost of raw materials, low efficiency of formic acid, etc., and achieve the effect of high energy density, uniform shape, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The invention provides a method for preparing a graphene nanodisk with controllable size and uniform appearance, comprising the following steps:

[0036] Using graphene oxide powder as raw material and concentrated nitric acid as solvent, graphene nanodisks with controllable size and uniform shape were prepared by hydrothermal method.

[0037] Preferably the present invention is raw material (the thickness of this graphene can be monolayer also can be multilayer) with the graphene oxide powder prepared by the improved Hummers method; Its concrete steps are as follows:

[0038] Weigh 1g of natural graphite, add 0.74g NaNO 3 with 34 mL of 98% H 2 SO 4 , mixed in an ice-water bath, stirring vigorously; later slowly add 5 g KMnO 4 , keep the temperature below 20°C, then transfer to a water bath at 35°C and stir for 3 hours; after stirring, add 250mL of deionized water, slowly add 4mL of 30%wt H 2 o 2 End the reaction; the obtained bright yellow suspension was first cen...

Embodiment 1

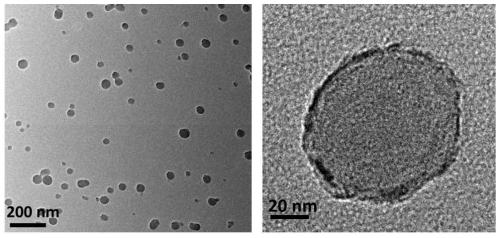

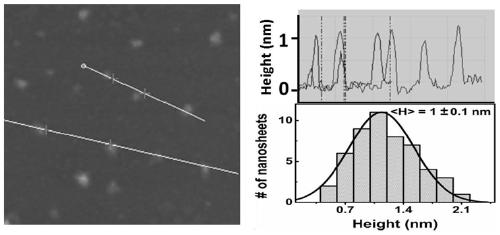

[0050] Embodiment 1: the preparation of the graphene nano disk that particle size is 70nm

[0051] Weigh 400 mg of dried graphene oxide powder, add 40 mL of concentrated nitric acid with a mass fraction of 65%, and stir ultrasonically for 3 hours until a uniformly dispersed solution is formed, then place it in a hydrothermal reaction kettle, and react at 160°C for 6 hours , after the reaction kettle was cooled to normal temperature, using rotary evaporation, centrifugation and dialysis, adding 4 to 5 times of distilled water to wash, collect, and dry to obtain graphene nanodiscs with a particle size of 70nm and a thickness of 1nm.

Embodiment 2

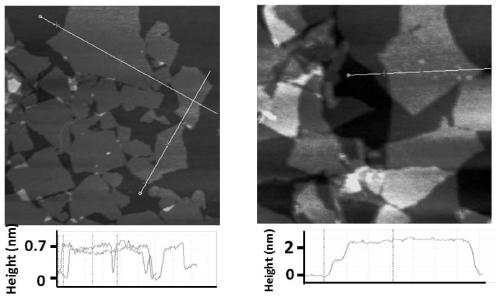

[0052] Embodiment 2: the preparation of the graphene nano-disc with a particle size of 180nm

[0053] Weigh 400mg of dried graphene oxide powder, add 40mL of concentrated nitric acid with a mass fraction of 65%, stir ultrasonically for 3 hours until a uniformly dispersed solution is formed, then place it in a hydrothermal reaction kettle, and react at 140°C for 4 hours , after the reaction kettle was cooled to normal temperature, using rotary evaporation, centrifugation and dialysis, adding 4 to 5 times of distilled water to wash, collect, and dry to obtain graphene nanodisks with a particle size of 180nm and a thickness of 1nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com