A kind of carbon nanotube produced in situ and its preparation method and application

A technology of carbon nanotubes and reactions, applied in the field of carbon nanotubes generated in situ and its preparation, to achieve good dispersion, good catalytic reduction effect, and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Embodiment 1: the synthesis of cross-linked polymer

[0062] In a 250mL beaker, add 100mL of cross-linking agent acetylacetone, and then add metal donor nickel acetylacetonate 0 / 50 / 100 / 250 / 500 / 1000 / 2000mg, fully sonicate until the nickel acetylacetonate is completely dissolved, then shake it vigorously at room temperature The reaction was stirred and 15 g NaOH was added rapidly. After 30 min, when the reaction solution became viscous, the stirring reaction was stopped. After the reaction, the reaction solution was left at room temperature for one week.

[0063] The reaction formula is as follows:

[0064]

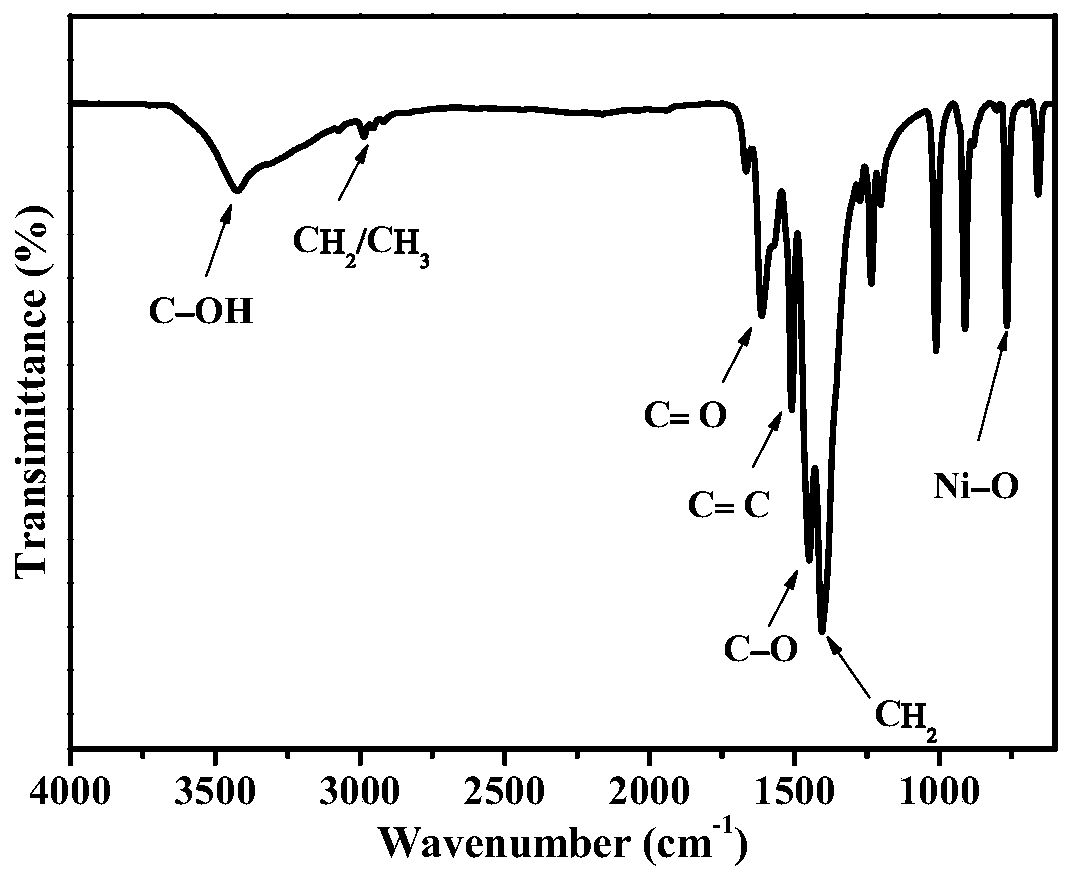

[0065] figure 1 It is a Fourier transform infrared spectrum (FT-IR) figure of the polymer precursor; As can be seen from the figure, the reaction mechanism of the polymer precursor obtained meets the mechanism of assumption;

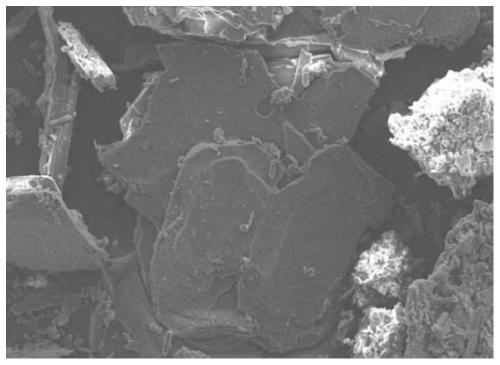

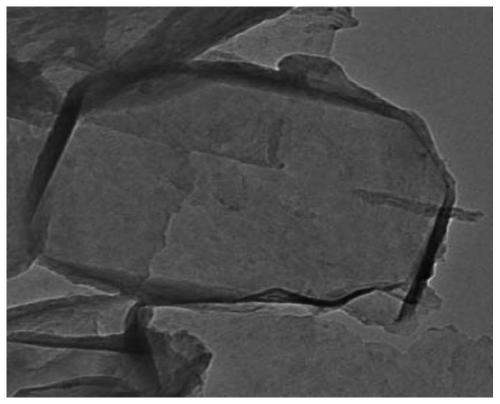

[0066] figure 2 is a scanning electron microscope (SEM) image of the polymer precursor; it can be seen from the figure that the obtai...

Embodiment 2

[0067] Embodiment 2: the preparation of carbon nanotube

[0068] The cross-linked polymer obtained in Example 1 is transferred to a porcelain boat, dried in an oven at 80°C for 12 hours, and then placed in a tube furnace. / 5 / 10 min -1 The heating rate is increased to the annealing temperature (respectively 400 / 500 / 600 / 700 / 800 / 900°C) under the protection of high-purity nitrogen for annealing, the annealing time is 0.5 / 1 / 2 / 4 / 6h, and then cooled to 50℃, the cooling rate is 5℃min -1 . Afterwards, the obtained carbon material was ground and ultrasonically dispersed in deionized water, filtered with suction, and rinsed with a large amount of deionized water. Afterwards, the filter cake was dried in an oven at 80° C. for 12 hours to obtain a carbon material with a purity of 80%. It can be seen from Table 1-3 that the inner diameter of the obtained carbon nanotubes is 5-30nm, the outer diameter is 10-50nm, the length is 20-200um, and the specific surface area is 50-200m 2 g -1 ,...

Embodiment 3

[0077] Embodiment 3: the reduction of p-nitrophenol

[0078] 13 mg of p-nitrophenol was dissolved in 2 mL of deionized water, and then 4 mg of the carbon nanotubes prepared in Example 2 were added as a catalyst. After sufficient ultrasonication for 15 min, 50 mg of sodium borohydride was added. To measure the rate of the reaction, pipette the reaction solution at 10uL min -1 Dilute it in 10 mL of deionized water, and then use a UV-visible spectrophotometer to measure the reaction effect.

[0079] Figure 8 It is the UV spectrum of in situ generated carbon nanotubes catalyzing the reduction of 4-nitrophenol; it can be seen from the figure that after 12 minutes, the reaction is complete. , to obtain pure 4-aminophenol. White crystals, melting point: 189-189.6°C. NMR spectrum (such as Figure 11 shown): 1 H NMR (600 MHz, DMSO) δ8.33 (s, 1H), 6.53–6.45 (m, 2H), 6.45–6.37 (m, 2H), 4.37 (s, 2H). Figure 12 shown): 13 C NMR (151MHz, DMSO) δ148.43, 140.52, 115.70, 115.54. GC-MS...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com