Optical-fiber ceramic ferrule and preparation method thereof

A ceramic ferrule and optical fiber technology, applied in the field of ceramic electronic components, can solve the problems of complex manufacturing process, insufficient precision, poor performance stability, etc., and achieve simple and easy preparation methods, high mechanical strength and precision, and equipment dependence. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

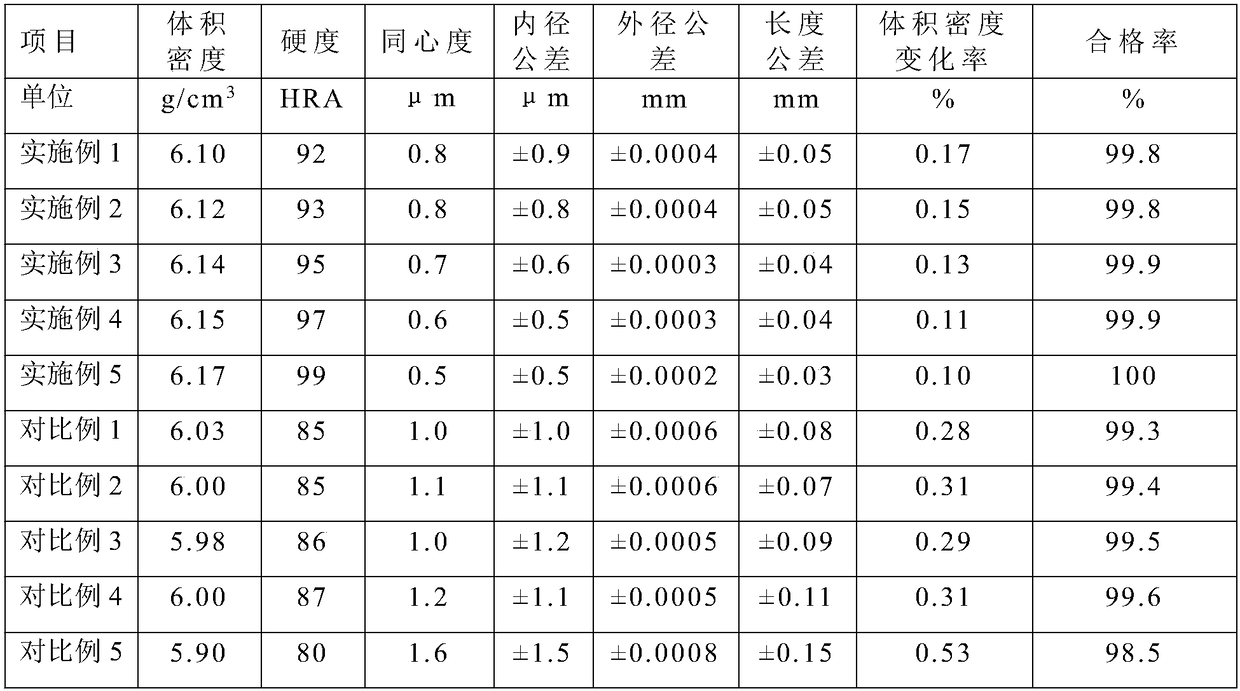

Examples

Embodiment 1

[0029] An optical fiber ceramic ferrule, made of the following raw materials in parts by weight: 90 parts of Zr-Cu-V-Re-Er-O-F, 3 parts of zirconium-based metal-organic framework, N-[β-(N,N-diacetic acid 1 part of aminoethyl]-γ-(N-acetoxy)aminopropyltrimethoxysilane, 6 parts of ionic paraffin polymer based on ethyl cyanoacrylate, 6 parts of SBS elastomer, methyl vinyl silicon 2 parts of rubber, 3 parts of ethylene-vinyl acetate copolymer.

[0030] The preparation method of the Zr-Cu-V-Re-Er-O-F comprises the following steps: 100 g of zirconium chloride, 0.5 g of copper chloride, 1 g of vanadium tetrachloride, 1 g of rhenium pentachloride and 1 g of praseodymium chloride, Dissolve 0.03g of ammonium bifluoride in 1000g of water, mix and stir for 1h, then dry in a blast drying oven at 100°C, cool to room temperature, ball mill, pre-burn at 700°C for 4h, cool to room temperature, take out and grind, and pass through 100 Mesh sieve to get Zr-Cu-V-Re-Er-O-F;

[0031] The preparati...

Embodiment 2

[0039] An optical fiber ceramic ferrule, made of the following raw materials in parts by weight: 92 parts of Zr-Cu-V-Re-Er-O-F, 4 parts of zirconium-based metal-organic framework, N-[β-(N,N-diacetic acid Base) aminoethyl]-γ-(N-acetoxy) aminopropyltrimethoxysilane 1.5 parts, ethyl cyanoacrylate based ionic paraffin polymer 7 parts, SBS elastomer 7 parts, methyl vinyl silicon 2.5 parts of rubber, 3.5 parts of ethylene-vinyl acetate copolymer.

[0040] The preparation method of said Zr-Cu-V-Re-Er-O-F comprises the steps of: mixing 100g of zirconium chloride, 0.6g of copper chloride, 1.5g of vanadium tetrachloride, 1.5g of rhenium pentachloride and praseodymium chloride 2g, 0.035g of ammonium bifluoride was dissolved in 1200g of water, mixed and stirred for 1.2h, then dried in a blast drying oven at 120°C, cooled to room temperature, ball milled, pre-calcined at 720°C for 4.3h, cooled to room temperature, and taken out Grind and pass through a 120-mesh sieve to obtain Zr-Cu-V-Re-...

Embodiment 3

[0049] An optical fiber ceramic ferrule, made of the following raw materials in parts by weight: 93 parts of Zr-Cu-V-Re-Er-O-F, 5 parts of zirconium-based metal-organic framework, N-[β-(N,N-diacetic acid Base) aminoethyl]-γ-(N-acetoxy) aminopropyltrimethoxysilane 2 parts, ethyl cyanoacrylate based ionic paraffin polymer 8 parts, SBS elastomer 8 parts, methyl vinyl silicon 3.5 parts of rubber, 4 parts of ethylene-vinyl acetate copolymer.

[0050] The preparation method of the Zr-Cu-V-Re-Er-O-F comprises the following steps: 100g of zirconium chloride, 0.8g of copper chloride, 2g of vanadium tetrachloride, 2g of rhenium pentachloride and 3g of praseodymium chloride, Dissolve 0.04g of ammonium bifluoride in 1500g of water, mix and stir for 1.6h, then dry in a blast drying oven at 106°C, cool to room temperature, ball mill, pre-burn at 760°C for 4.6h, cool to room temperature, take out and grind, Pass 160 mesh sieve to get Zr-Cu-V-Re-Er-O-F;

[0051] The preparation method based...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com