Foam pressure-sensitive adhesive product, and preparation method thereof

A pressure-sensitive adhesive and foam technology, which is applied in the field of pressure-sensitive adhesives, can solve the problems of poor adhesion, non-removable peeling, and poor heat-and-moisture resistance of foam pressure-sensitive adhesives, and achieves improved labor efficiency and strong adhesion. The effect of improving the bonding performance and improving the bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

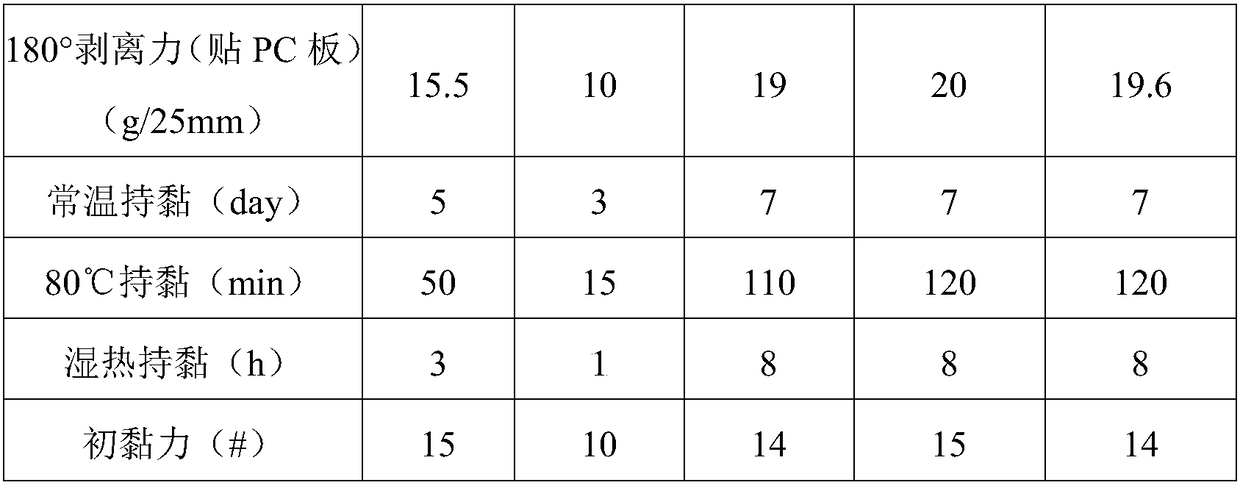

Examples

Embodiment 1

[0027] (1) Weigh 3g of methyl acrylate, 1g of ethyl methacrylate, 25g of butyl acrylate, 10g of decyl methacrylate, 0.5g of acrylic acid, 0.5g of hydroxyethyl acrylate, and 60g of ethyl acetate, mix well, and add In the kettle, heat to 75-76°C, and pass nitrogen throughout;

[0028] (2) Add 0.1g of dibenzoyl peroxide into the reaction kettle, control the temperature at 75-76°C, and react for 1.5h;

[0029] (3) After raising the temperature to 85°C, keep it warm for 1.5 hours, then cool it down to room temperature naturally, and discharge.

[0030] (4) Take by weighing the part of the glue that is discharged in the step (3), add triglycidyl isocyanurate, toluene diisocyanate, polyester to it, and the addition consumption is respectively 0.5% of the total weight of the glue that has been weighed , 0.5%, 1%, stir well, apply the obtained glue on the release film, first cure at room temperature for 5 minutes, then cure at 80°C for 5 minutes, and finally cure at 120°C for 5 minute...

Embodiment 2

[0032] (1) Weigh 6g of methyl acrylate, 2g of phenyl methacrylate, 20g of isooctyl acrylate, 10g of decyl methacrylate, 1g of acrylic acid, 1g of hydroxypropyl acrylate, 50g of ethyl acetate, and 10g of toluene and mix well, Add it to the reaction kettle, heat it to 75-76°C, and pass nitrogen throughout;

[0033] (2) Add 0.12g of dibenzoyl peroxide into the reaction kettle, control the temperature at 75-76°C, and react for 1.5h;

[0034] (3) After raising the temperature to 85°C, keep it warm for 1.5 hours, then cool it down to room temperature naturally, and discharge.

[0035] (4) Take by weighing the part of the glue solution discharged in the step (3), add hexamethylene diisocyanate, m-xylylenediamine type epoxy resin, terpene therein, and the addition amount is respectively the glue solution amount taken by weighing 0.1%, 0.5%, 2% of the total weight, fully stirred, the obtained glue is coated on the release film, first cured at room temperature for 5 minutes, then cured...

Embodiment 3

[0037] (1) Weigh 8g of methyl acrylate, 2g of isobutyl methacrylate, 15g of isooctyl acrylate, 10g of decyl methacrylate, 3g of acrylic acid, 2g of 4-hydroxybutyl acrylate, and 60g of toluene and mix well, add In the reaction kettle, heat to 75-76°C and pass nitrogen throughout;

[0038] (2) Add 0.2g of dibenzoyl peroxide into the reaction kettle, control the temperature at 75-76°C, and react for 1.5h;

[0039] (3) After raising the temperature to 85°C, keep it warm for 1.5 hours, then cool it down to room temperature naturally, and discharge.

[0040] (4) Take by weighing the part glue solution of discharging in step (3), add triglycidyl isocyanurate, terpene, terpene phenolic resin wherein, the addition consumption is respectively 0.1% of the glue solution amount gross weight that takes by weighing , 2%, 3%, stir well, apply the obtained glue on the release film, first cure at room temperature for 5 minutes, then cure at 80°C for 5 minutes, and finally cure at 120°C for 5 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com