Oligomeric viscoelastic surfactant, synthesis method and viscous acid formula

A technology of a surfactant and a synthesis method, which is applied in the synthesis method and its thickening acid formula, and the field of oligomeric configuration viscoelastic surfactants, can solve the problems of unreported and high cost of surfactant use, and achieves improved performance. The effect of mining efficiency, low synthesis cost and low concentration of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The synthetic product of this example is a hexameric configuration viscoelastic surfactant.

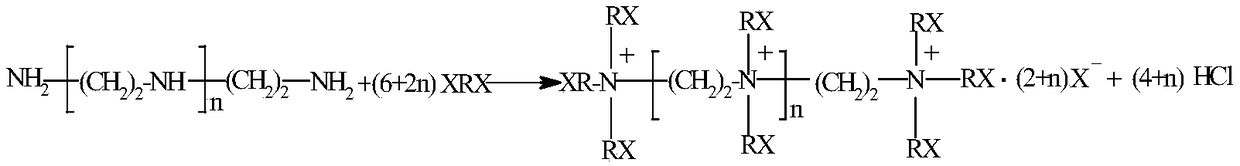

[0032] First, to synthesize the intermediate quaternary ammonium salt polyhaloalkane, add appropriate amount of ethylenediamine, 1,3-dichloropropane, potassium carbonate and ethylene glycol solvent into the reaction kettle, wherein ethylenediamine, 1,3-dichloro The molar ratio of propane and potassium carbonate is 1:6:3 The ratio of the mass of ethylene glycol solvent to the sum of the mass of reactants ethylenediamine, 1,3-dichloropropane and potassium carbonate is 2:3. During the reaction, the reaction kettle Raise the temperature to 50°C, react for 3 hours, continue to heat up to 95°C, react for 9 hours, and cool to room temperature to obtain a mixture A1 containing quaternary ammonium salt polyhalogenated alkanes intermediates with the following structure. During the reaction, potassium carbonate is used for absorption. hydrochloric acid, the reaction formula of this step i...

Embodiment 2

[0039] The synthesized product in this example is a decamer configuration viscoelastic surfactant.

[0040] First, to synthesize the intermediate quaternary ammonium salt polyhaloalkane, add an appropriate amount of triethylenetetramine, 1,3-dichloropropane, potassium carbonate and ethylene glycol solvent into the reactor, wherein triethylenetetramine, 1,3- The molar ratio of dichloropropane and potassium carbonate is 1:10:3, and the ratio of the quality of ethanol solvent to the mass sum of reactants triethylenetetramine, 1,3-dichloropropane and potassium carbonate is 2:3. During the reaction, Heat the reaction kettle to 55°C, react for 3 hours, continue to heat up to 95°C, react for 9 hours, and cool to room temperature to obtain a mixture A2 containing a quaternary ammonium salt polyhalogenated alkanes intermediate with the following structure. During the reaction, potassium carbonate is used to absorb The hydrochloric acid produced in the reaction, the reaction formula of ...

Embodiment 3

[0048] The synthesized product in this example is a fourteen-mer configuration viscoelastic surfactant.

[0049] First, to synthesize the intermediate quaternary ammonium salt polyhaloalkane, add an appropriate amount of pentaethylene hexamine, 1,3-dibromopropane, sodium carbonate and 1-2 propanol solvent into the reactor, wherein pentaethylene hexamine, 1, The molar ratio of 3-dibromopropane and sodium carbonate is 1:14:4, the ratio of the mass of 1-2 propanol solvent to the mass sum of reactants triethylenetetramine, 1,3-dichloropropane and sodium carbonate is 2: 3. During the reaction, heat the reactor to 60°C, react for 2.5 hours, continue to heat up to 95°C, react for 9 hours, and cool to room temperature to obtain a mixture A3 containing a quaternary ammonium salt polyhalogenated alkanes intermediate with the following structure. During the reaction , potassium carbonate is used to absorb the hydrochloric acid produced in the reaction, and the reaction formula of this st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com