Pulse power ceramic capacitor, end electrode and fabrication method of end electrode

A technology of ceramic capacitors and pulse power, which is applied in the direction of fixed capacitor electrodes, fixed capacitor dielectrics, and fixed capacitor terminals, etc., which can solve the problems of reducing the reliability of capacitors, weak connection between terminal electrodes and ceramic dielectrics, and poor solderability of terminal electrodes. , to achieve the effect of improving weldability, excellent adhesion and weldability, and high weldability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

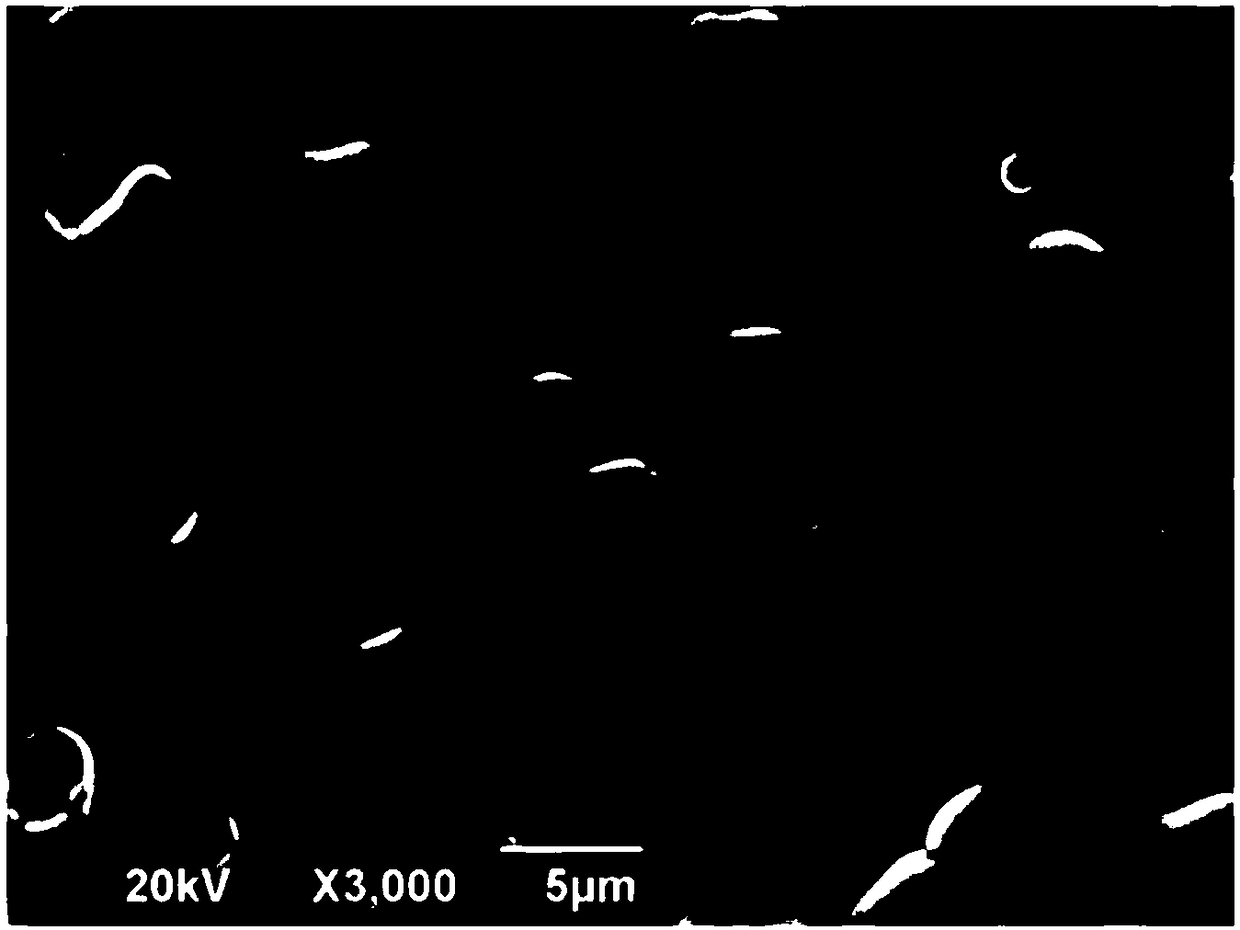

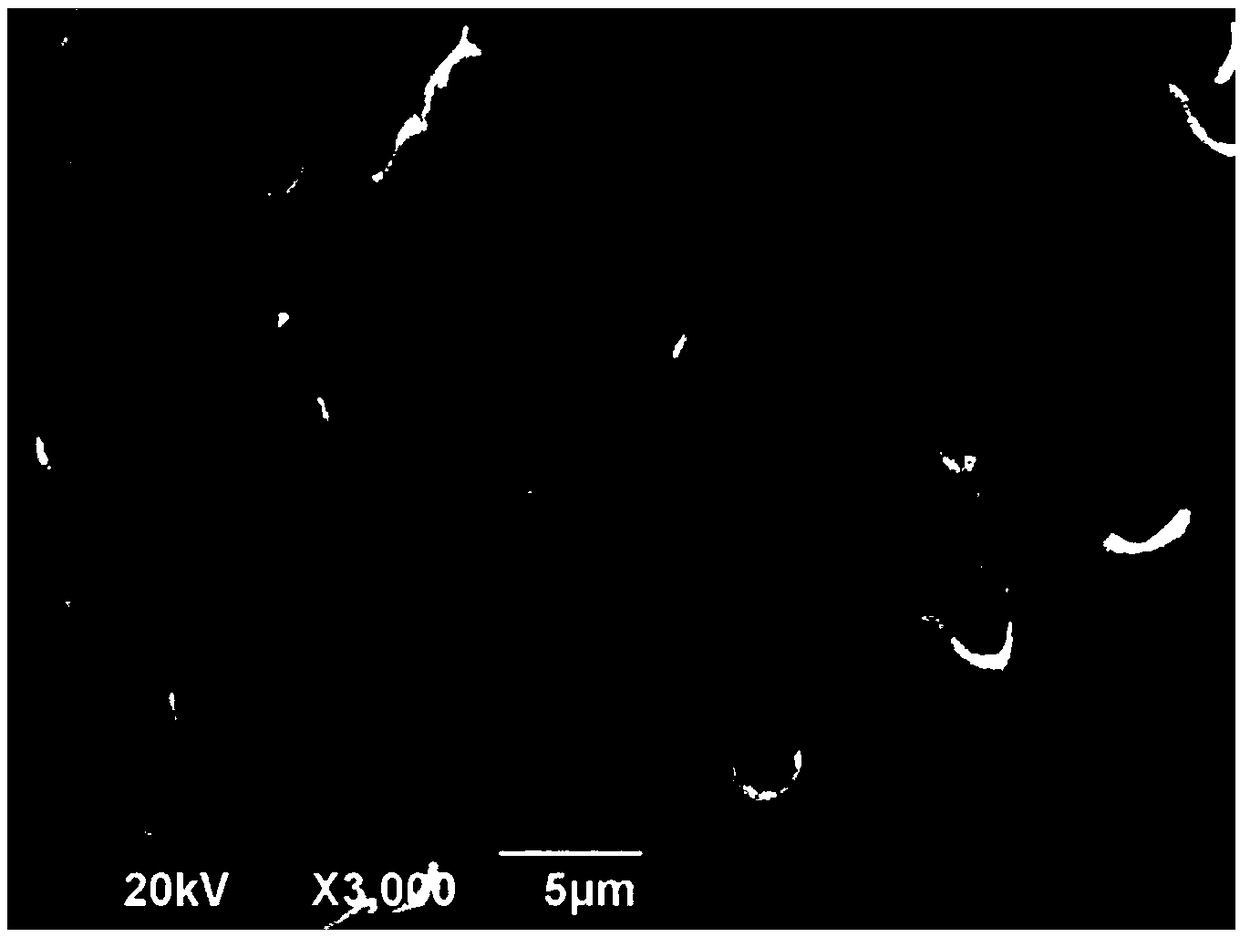

Image

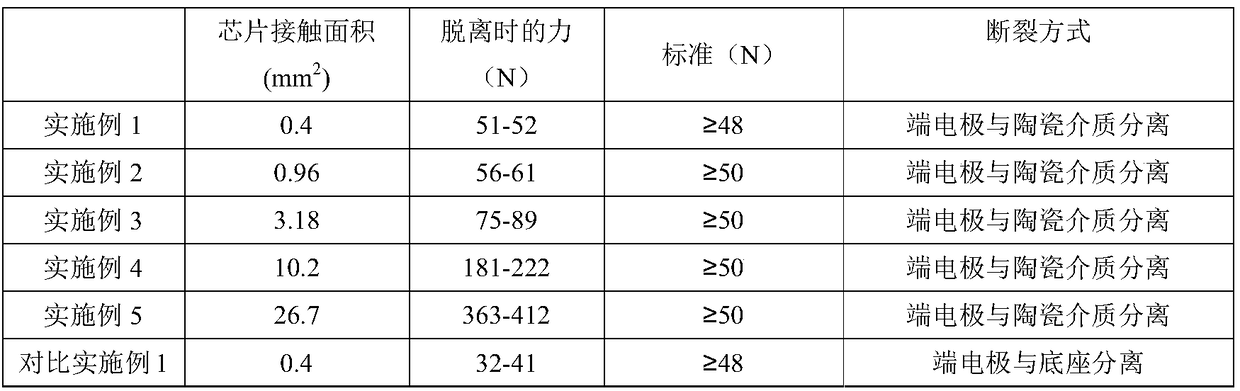

Examples

Embodiment 1

[0022] Preparation of electrode paste A: 3 parts of ZnO-BaO-SiO 2 , 73 parts of silver-palladium mass ratios are silver-palladium alloy powders of 75:25, 4 parts of ethyl cellulose, 20 parts of terpineol are mixed uniformly, grinder grinds, and electrode slurry A is obtained;

[0023] Preparation of electrode paste B: 0.5 parts of ZnO-BaO-SiO 2 , 1.5 Bi 2 o 3 , 73 parts of silver-palladium alloy powder with a silver-palladium mass ratio of 75:25, 5 parts of ethyl cellulose and 20 parts of terpineol were mixed uniformly, and ground by a grinder to prepare electrode slurry B.

[0024] Coating electrode slurry A on the ceramic medium for sealing, drying in a dryer, sintering in a sintering furnace to obtain a layer A electrode, and then coating electrode slurry B on the layer A electrode for sealing end, and then sintered in a sintering furnace to solidify the electrode slurry B to obtain a terminal electrode with A and B layer electrodes. In this embodiment, the thickness of...

Embodiment 2

[0026] Preparation of electrode slurry A: 7 parts of ZnO-BaO-SiO2, 68 parts of silver-palladium alloy powder with a silver-palladium mass ratio of 75:25, 5 parts of ethyl cellulose, and 20 parts of terpineol are mixed evenly and ground by a grinder , to prepare electrode slurry A;

[0027] Preparation of electrode slurry B: Mix 1 part of ZnO-BaO-SiO2, 3 parts of Bi2O3, 73 parts of silver-palladium alloy powder with a silver-palladium mass ratio of 75:25, 5 parts of ethyl cellulose and 18 parts of terpineol evenly 1. Grinding with a grinding machine to obtain electrode slurry B.

[0028] Coating electrode slurry A on the ceramic medium for sealing, drying in a dryer, sintering in a sintering furnace to obtain a layer A electrode, and then coating electrode slurry B on the layer A electrode for sealing terminal, and then sintered in a sintering furnace to solidify the electrode paste B to obtain a terminal electrode. The thickness of the A-layer electrode is 40um, the thicknes...

Embodiment 3

[0030] Preparation of electrode slurry A: 5 parts of ZnO-BaO-SiO2, 70 parts of silver-palladium alloy powder with a silver-palladium mass ratio of 75:25, 5 parts of ethyl cellulose, and 20 parts of terpineol are mixed evenly and ground by a grinder , to prepare electrode slurry A;

[0031] Preparation of electrode slurry B: 0.8 parts of ZnO-BaO-SiO2, 2 parts of Bi2O3, 73 parts of silver-palladium alloy powder with a silver-palladium mass ratio of 75:25, 4.2 parts of ethyl cellulose and 20 parts of terpineol were mixed evenly 1. Grinding with a grinding machine to obtain electrode slurry B.

[0032] Coating electrode slurry A on the ceramic medium for sealing, drying in a dryer, sintering in a sintering furnace to obtain a layer A electrode, and then coating electrode slurry B on the layer A electrode for sealing terminal, and then sintered in a sintering furnace to solidify the electrode paste B to obtain a terminal electrode. In this embodiment, the thickness of the A-layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com