Device and process for producing water special for making tea

A process and water tank technology, applied in the field of equipment for producing tea-making water, can solve problems such as inability to perfectly satisfy tea brewing, and achieve the effects of improving indigestion, high dissolved oxygen, and small water molecular clusters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

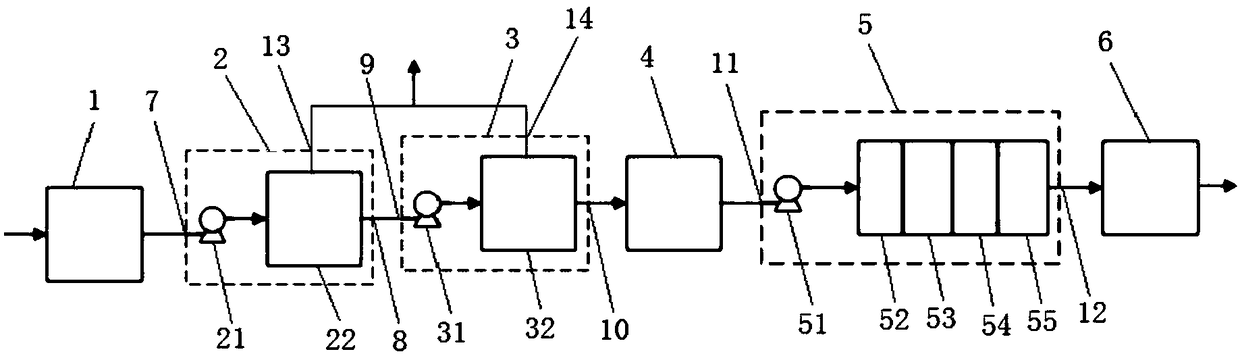

[0033] This embodiment is used to illustrate the structure of the device for producing tea-making water according to the present invention. like figure 1 As shown, the device includes a raw water tank 1, a first-level nanofiltration unit 2, a second-level nanofiltration unit 3, a water storage tank 4, a fourth-level electrolysis unit 5, and a finished water tank 6, wherein the water inlet 7 of the first-level nanofiltration unit 2 Connected with the water outlet of the raw water tank, the clear liquid outlet 8 of the primary nanofiltration unit 2 is connected with the water inlet 9 of the secondary nanofiltration unit 3, and the clear liquid outlet 10 of the secondary nanofiltration unit passes through the water storage tank 4 and the fourth The water inlet 11 of the first-level electrolysis unit 5 is connected, the water outlet 12 of the fourth-level electrolysis unit is connected with the water inlet of the finished water tank, the concentrated liquid outlet 13 of the first-...

Embodiment 2

[0043] This embodiment is used to illustrate the process for producing tea-making water of the present invention. The special water for making tea has been spring water since ancient times, so this process chooses rock crevice spring water that meets the "National Drinking Water Standard" as the raw water. The process for producing special water for making tea comprises the following steps:

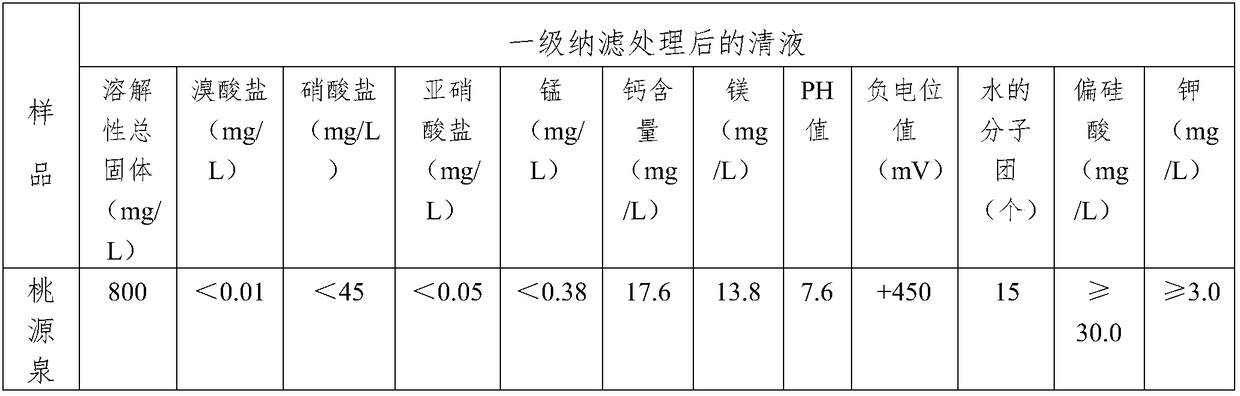

[0044] 1) Perform primary nanofiltration treatment on the raw water to remove impurities in the raw water;

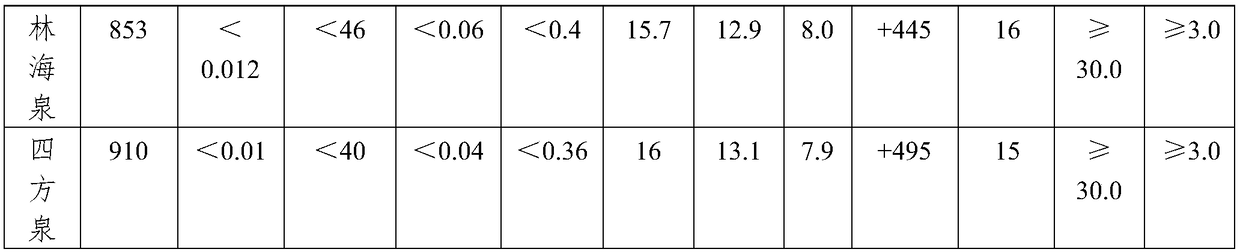

[0045] 2) Perform secondary nanofiltration treatment on the clear liquid obtained in step 1), remove most of the metal ions to reduce the hardness of the water, and simultaneously reduce the content of substances that affect the taste of the water and the color of the tea soup;

[0046] 3) The clear liquid obtained in step 2) is subjected to first-level electrolysis, second-level electrolysis, third-level electrode, and fourth-level electrolysis in order to finally obtain finished...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com