A method for improving corrosion resistance of coral concrete structures

A concrete structure and concrete technology, which is applied in the field of improving the corrosion resistance of coral concrete structures, can solve the problems of poor durability of coral concrete structures and corrosion of steel bars, and achieve the effects of reducing the risk of corrosion, short construction period and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for improving the corrosion resistance of coral concrete structures, comprising the following steps:

[0031] Step 1, preparation of modified epoxy asphalt coated steel bars: at room temperature, by brushing, the coating thickness is 40±2 μm;

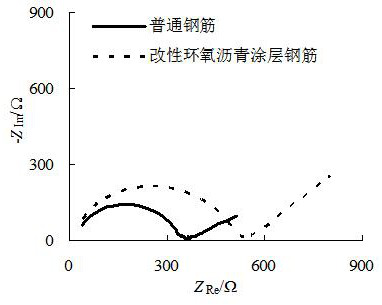

[0032] Step 2, molding of reinforced coral concrete members and seawater exposure: forming ordinary reinforced coral concrete members and modified epoxy asphalt-coated reinforced coral concrete members according to the established mix ratio, removing the formwork and curing for 28 days, then performing seawater exposure for 0, 28, and 90 days and 180d;

[0033] Step 3, electrochemical test: at room temperature, use an electrochemical workstation to perform AC impedance spectroscopy testing, the scanning frequency is 10 mHz ~ 100 kHz, and the impedance test signal is a sine wave with an amplitude of 10 mV to obtain corals with different exposure times. Nyquist curves for steel bars in concrete.

Embodiment 2

[0035] A method for improving the corrosion resistance of coral concrete structures, comprising the following steps:

[0036] Step 1, preparation of modified epoxy asphalt coated steel bars: at room temperature, by brushing, the coating thickness is 40±2 μm;

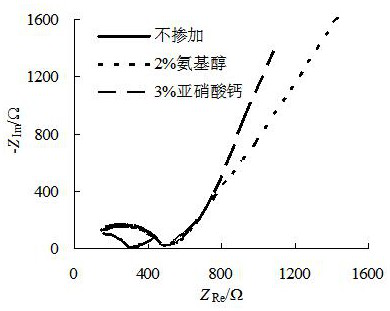

[0037] Step 2, molding of reinforced coral concrete components and exposure to seawater: forming coral concrete components without adding, adding 3% calcium nitrite rust inhibitor and adding 2% amino alcohol rust inhibitor according to the established mix ratio, demoulding, After 28 days of curing, seawater exposure was carried out for 0, 28, 90 and 180 days;

[0038]Step 3, electrochemical test: at room temperature, use an electrochemical workstation to perform AC impedance spectroscopy testing, the scanning frequency is 10 mHz ~ 100 kHz, and the impedance test signal is a sine wave with an amplitude of 10 mV to obtain corals with different exposure times. Nyquist curves for steel bars in concrete.

Embodiment 3

[0040] A method for improving the corrosion resistance of coral concrete structures, comprising the following steps:

[0041] Step 1, preparation of modified epoxy asphalt coated steel bars: at room temperature, by brushing, the coating thickness is 40±2 μm;

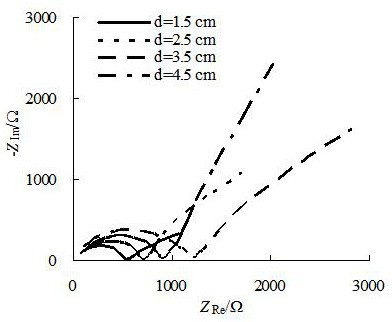

[0042] Step 2: Reinforced coral concrete member forming and seawater exposure: Coral concrete members with a protective layer thickness of 1.5, 2.5, 3.5, 4.5, 5.5 and 7 cm were formed according to the predetermined mix ratio, and the seawater exposure was performed after demoulding and curing for 28 days. , 28, 90 and 180 d;

[0043] Step 3, electrochemical test: at room temperature, use an electrochemical workstation to perform AC impedance spectroscopy testing, the scanning frequency is 10 mHz ~ 100 kHz, and the impedance test signal is a sine wave with an amplitude of 10 mV to obtain corals with different exposure times. Nyquist curves for steel bars in concrete.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com