Improvement method of preparation technique of 3-(2,2,2-trimethylhydrazine) propionate dihydrate

A technology of trimethylhydrazine and dihydrate, which is applied in the preparation of hydrazine, organic chemistry and other directions, can solve the problems of difficulty in meeting the standards of raw materials, many types of residual impurities, and reduced product yield, etc., and achieves commercial large-scale production. , The equipment is easy to operate, and the effect of acidizing time and process is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

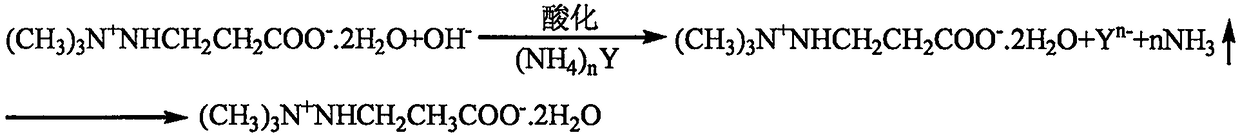

Method used

Image

Examples

Embodiment 1

[0017] Take 67g of potassium hydroxide (90%) and add it into 470ml of ethanol to dissolve it. When the temperature drops to 18-20°C, add 121g of 3-(2,2,2-trimethylhydrazine) methyl propionate bromide. Temperature control 18-20 Hydrolyze at ℃ (use TLC to detect whether the reaction is terminated), filter the precipitate when the temperature drops to 2 to 4 ℃, remove the inorganic precipitate, wash with 2*20ml ethanol, add a certain amount of NaOC after the washing liquid and the mother liquor are combined 2 h 5 Aqueous solution repassed CO 2 Acidify the gas to a pH of 8.2-8.5 (tested by a pH meter), filter off the formed precipitate, wash with 2*20ml ethanol, and combine the washing liquid. After inspection, the mother liquor still has a small amount of double salt milky, so add a certain amount to the mother liquor NaOC 2 h 5 The aqueous solution was stirred and left for about 15 minutes, and the milky state became clear to produce granular precipitates, and then the remain...

Embodiment 2

[0019]Take 67g of potassium hydroxide (90%) and add it into 470ml of ethanol to dissolve it. When the temperature drops to 18-20°C, add 145g of 3-(2,2,2-trimethylhydrazine) methyl propionate sulfate. Temperature control 18-20 Hydrolyze at ℃ (use TLC to detect whether the reaction is terminated), filter the precipitate when the temperature drops to 2 to 4°C, remove the inorganic precipitate, wash with 2*20ml ethanol, combine the washing liquid and the mother liquor and pass through SO 2 Acidify the gas to PH of 8.2-8.5 (PH acidity meter test), filter off the formed precipitate, wash with 2*20ml ethanol, combine the mother liquor of the washing liquid (the clear solution cannot be obtained by milk filtration method), and add a certain amount of CaCl 2 The aqueous solution was stirred and left to stand for about 15 minutes, and the milky state became clear to produce granular precipitates, and then the remaining inorganic salts were filtered out, and the obtained clear solution w...

Embodiment 3

[0021] Take 67g of potassium hydroxide (90%) and add it into 470ml of ethanol to dissolve it. When the temperature drops to 18-20°C, add 145g of 3-(2,2,2-trimethylhydrazine) methyl propionate sulfate. Temperature control 18-20 Hydrolyze at ℃ (use TLC to detect whether the reaction is terminated), filter the precipitate when the temperature drops to 2 to 4°C, remove the inorganic precipitate, wash with 2*20ml ethanol, combine the washing liquid and the mother liquor and pass through SO 2 The gas is acidified to a pH of 8.2-8.5 (tested by a pH meter), and the formed precipitate is filtered off, washed with 2*20ml of ethanol, combined with the mother liquor of the wash (milk filtration method cannot obtain a clear solution), and finally purified by electrodialysis. Concentrate under reduced pressure, cool and crystallize, dry to obtain 88g, 3-(2,2,2-trimethylhydrazine) propionate dihydrate crude drug raw material about 97%, recrystallize with isopropanol or ethanol, melting point ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com