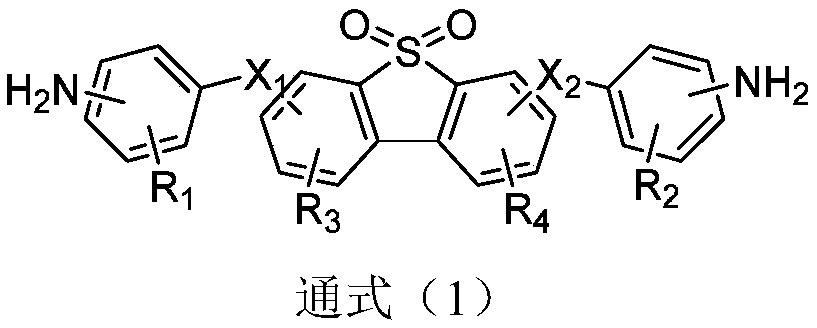

Diamine compound for preparing liquid crystal aligning agent and application of diamine compound

A liquid crystal aligning agent, amine compound technology, applied in liquid crystal materials, organic chemistry, chemical instruments and methods, etc., can solve the problems of poor stability, electrostatic interference, poor orientation, etc., and achieve good electron transmission ability and antistatic performance. Strong and good orientation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

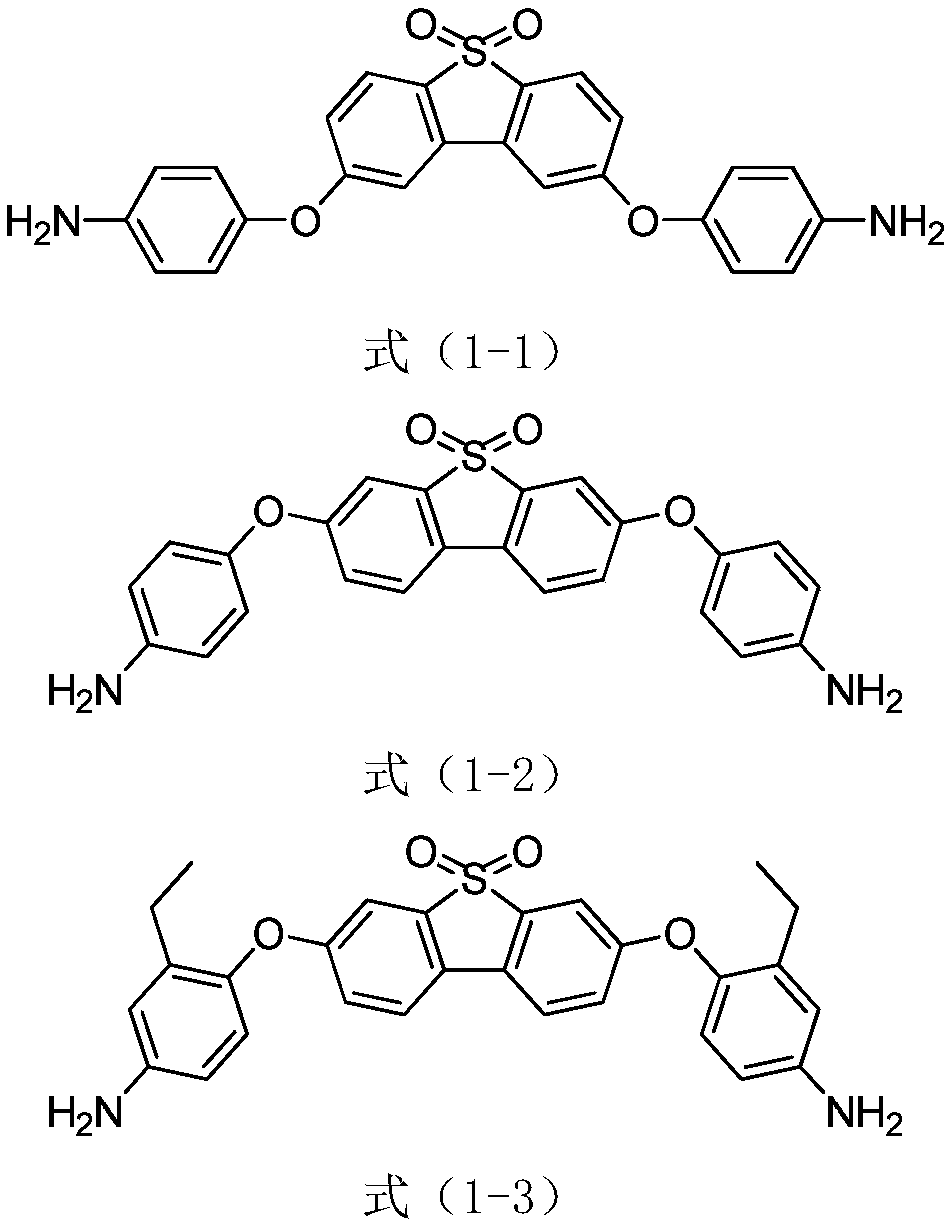

Synthetic example 1

[0052] The compound represented by structural formula (1-1) can be synthesized according to the following synthetic route 1:

[0053]

[0054] (1) Synthesis of compound b-1-1a

[0055] 2,8-dihydroxydibenzosulfolane (24.8g, 100mmol), p-nitrochlorobenzene (33.1g, 210mmol), anhydrous potassium carbonate (8.28g, 210mmol) were put into a 1000mL three-necked round bottom flask. 60 mmol) and 300 g of toluene, the bath temperature was raised to 110 °C, stirred and refluxed for 3 hours, followed by TLC until the raw material 2,8-dihydroxydibenzosulfolane had no remaining, the system was lowered to room temperature, the stirring was stopped, and the reaction solution was transferred. In the separatory funnel, wash with water until neutral, remove the solvent toluene to obtain a yellow solid, add 240 g of absolute ethanol and 120 g of THF, stir for 30 min, and filter with suction, and dry the filter cake to obtain 41.69 g of yellow crystals. The product is measured by HPLC-MS, m / z= 4...

Synthetic example 2

[0060] The compounds represented by the structural formulae (1-2) to (1-4) can be synthesized according to the synthetic route 1 by using each dibenzosulfolane compound and each parent nitrobenzene compound. The specific yield, high-resolution mass spectrometry results and elemental analysis results of each product are shown in Table 1 below. In Table 1, Synthesis Examples 2-4, high-resolution mass spectrometry is HPLC-MC, and [M+1] is used to characterize the corresponding compound The molecular ion peak of :

[0061] Table 1 Yield, mass spectrum and elemental analysis data of each compound in Synthesis Examples 2-4

[0062]

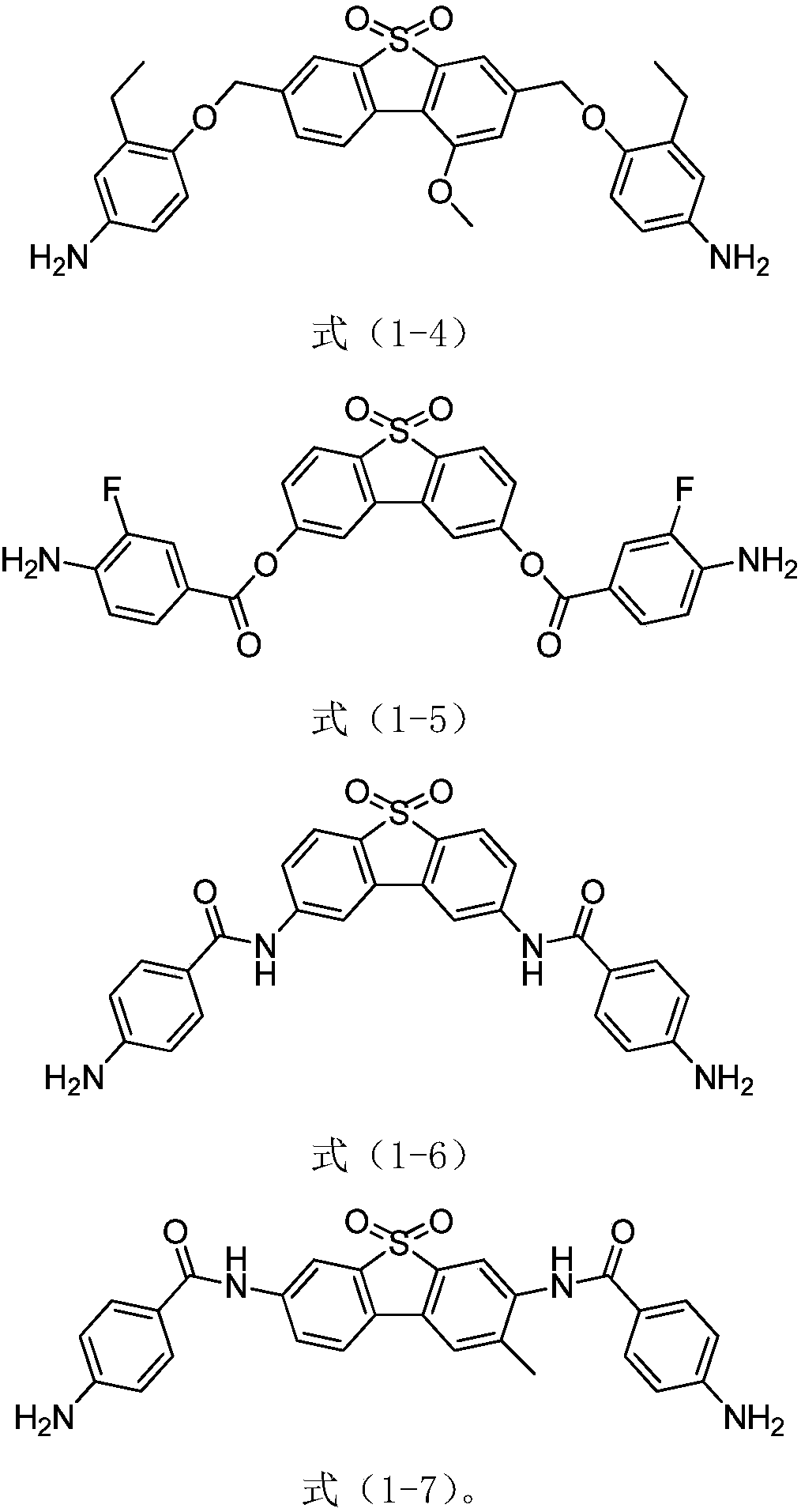

Synthetic example 5

[0064] The compound represented by structural formula (1-5) can be synthesized according to the following synthetic route 2:

[0065]

[0066] (1) Synthesis of compound b-1-5a

[0067] 3,7-dicarboxydibenzosulfolane (30.43 g, 100 mmol), 3-fluoro-4-nitrophenol (32.99 g, 210 mmol), DCC (43.30 g) were put into a 1000 mL three-necked round-bottomed flask , 210 mmol) and 500 g of toluene, the bath temperature was raised to 110 ° C and stirred for 3 hours, followed by TLC until the raw material 3,7-dicarboxydibenzosulfolane had no residue, the system was lowered to room temperature and suction filtered, and the filtrate was concentrated to weight For 140g, add 200g of ethanol, a yellow solid is precipitated, suction filtration, dry the filter cake to obtain 44.81g of yellow crystals, the product is detected by HPLC-MS, m / z=582.02, confirmed to be the target product b-1-5a, with 3, Using 7-dicarboxydibenzosulfolane as a standard calculation, the reaction yield was 82%.

[0068] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com