A kind of phase change energy storage microsphere and preparation method thereof

A phase change energy storage and phase change microsphere technology, applied in the field of phase change energy storage microspheres and their preparation, can solve the problems of phase change energy storage efficiency loss, cost of heat preservation and energy saving materials, and no resistance to mechanical stirring friction, etc. Ensure long-term performance, convenient production and implementation, and simple wrapping process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

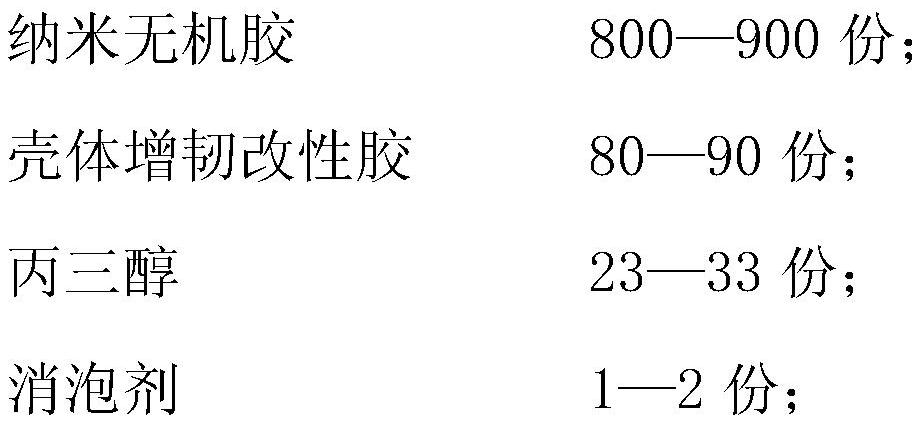

[0057] A preparation method of phase-change energy storage microspheres, the steps comprising:

[0058] (1) Add polyethylene glycol and 46# paraffin into a mixing tank with heating function and spraying function according to the proportion, raise the temperature to 60-70°C, dissolve polyethylene glycol and 46# paraffin into liquid, stir and mix evenly , at 80-100 rpm, stirring for 3-5 minutes to obtain a phase-change mixture;

[0059] (2) Add the inorganic open-pore perlite into another dry powder mixer with heating function, heat the inorganic open-pore perlite to 50-60°C; continue stirring, and then raise the temperature to 60-70°C The phase-change mixture liquid at ℃ is sprayed on the inorganic open-pore perlite being stirred by high-pressure spraying, so that it can be stirred evenly and no lumps are bonded together. Due to the adsorption of the capillary, the phase change mixture will be absorbed by the pores of the inorganic open-pore perlite, and the phase change mixtu...

Embodiment 3

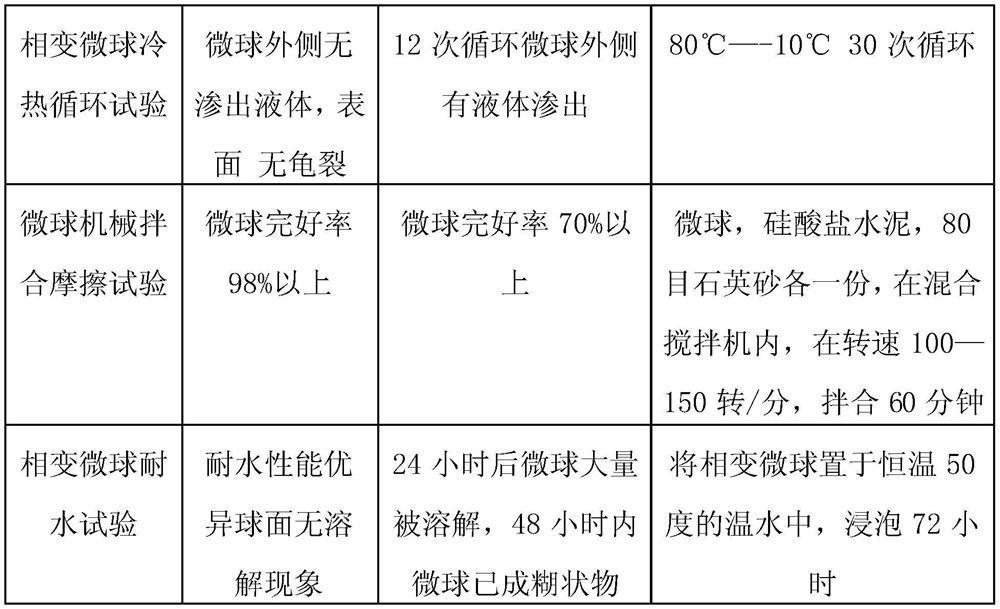

[0071] The basic performance comparison between Example 3 and Comparative Example 1 is shown in Table 2.

[0072] Table 2 Basic performance table

[0073]

[0074]

[0075] The difference between Example 3 and Comparative Example 1 lies in the use of different main binders and shell reinforcing materials. The cooling and heating cycle of the phase change microspheres in Example 3 is much better than that of Comparative Example 1, which fully demonstrates that the compactness of nano-silica sol is better than that of sodium silicate, and the packing density of mica powder is much better than that of calcium carbonate. Water resistance nano silica sol is far superior to sodium silicate.

[0076] Table 3 of the cement-based thermal insulation mortar prepared with the phase change energy storage microspheres prepared in Example 3 of the present invention.

[0077] Table 3 The phase change energy storage microspheres prepared in Example 3 to prepare cement-based thermal ins...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com