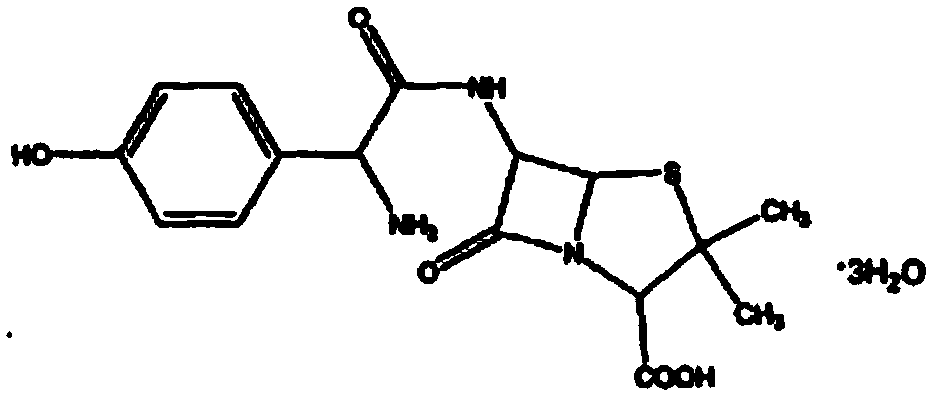

Method for synthetizing amoxicillin through enzymatic method

A technology for amoxicillin and enzymatic synthesis, which is applied in the field of enzymatic synthesis of amoxicillin, can solve the problems of amoxicillin stability, which are few, and does not involve the stability of amoxicillin, and achieves good clarity. , shorten the reaction time, good effect of purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

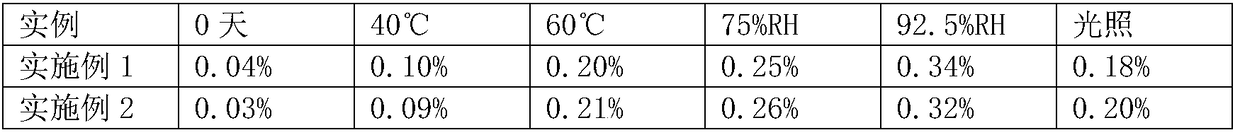

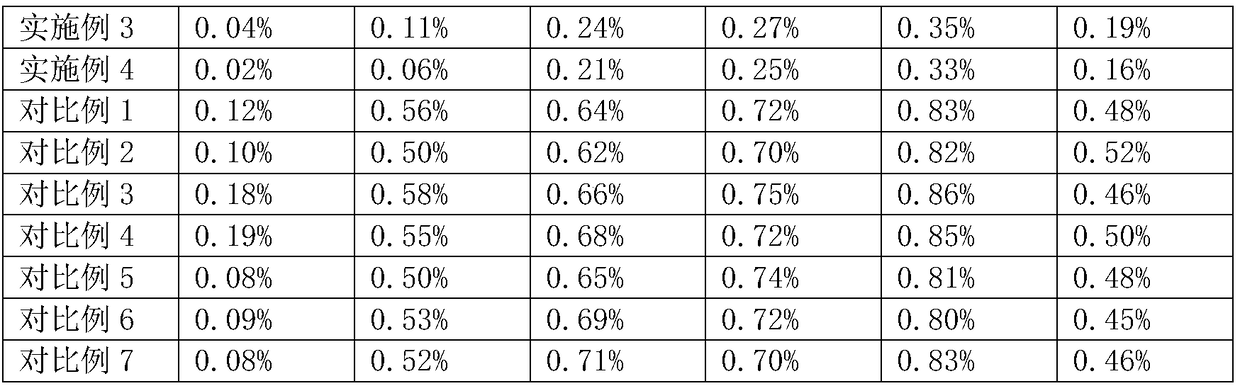

Embodiment 1

[0043] Embodiment 1 A kind of method of enzymatic synthesis of amoxicillin

[0044] Specifically include the following steps:

[0045] (1) First take immobilized penicillin G acylase, control its dosage to be 2KU / L, and after cleaning it with distilled water, add a concentration of 3mol / L hydrochloric acid solution, soak for 5min, then drop into the enzyme reactor, Drain water;

[0046] (2) Weigh p-hydroxyphenylglycine methyl ester and 6-APA, control the molar ratio of the two to 1:1, mix the two evenly, add a hydrochloric acid solution with a concentration of 3mol / L, soak for 20min, then add pure water and mass Ratio is 3:1 sucrose and histidine, drop into the enzyme reactor that adds penicillin G acylase described in step (1);

[0047] (3) Turn on stirring and control the stirring speed to 300r / min, use 3mol / L ammonia water to control the pH value to 6.5, and use a circulating refrigerator to control the temperature to 10°C, until the conversion rate of 6-APA no longer inc...

Embodiment 2

[0049] Embodiment 2 A kind of method of enzymatically synthesizing amoxicillin

[0050] Specifically include the following steps:

[0051] (1) First take the immobilized penicillin G acylase, control its dosage to 2.1KU / L, and wash it with distilled water, then add a hydrochloric acid solution with a concentration of 3.5mol / L, soak for 6min, and then put it into the enzyme reactor medium, drained;

[0052] (2) Weigh p-hydroxyphenylglycine methyl ester and 6-APA, control the molar ratio of the two to 1.1:1, mix the two evenly, add a hydrochloric acid solution with a concentration of 3.5mol / L, soak for 25min, then add pure water and Mass ratio is 3: 1 sucrose and histidine, drop into the enzyme reactor that adds penicillin G acylase described in step (1);

[0053] (3) Turn on stirring and control the stirring speed to be 350r / min, use 3.5mol / L ammonia water to control the pH value to 6.6, and use a circulating freezer to control the temperature to 12°C until the conversion rat...

Embodiment 3

[0055] Embodiment 3 A kind of method of enzymatic synthesis amoxicillin

[0056] Specifically include the following steps:

[0057] (1) First take the immobilized penicillin G acylase, control its dosage to 2.4KU / L, and wash it with distilled water, then add a hydrochloric acid solution with a concentration of 4mol / L, soak for 8min, and then put it into the enzyme reactor , drain the water;

[0058] (2) Weigh p-hydroxyphenylglycine methyl ester and 6-APA, control the molar ratio of the two to 1.2:1, mix the two evenly, add a hydrochloric acid solution with a concentration of 4mol / L, soak for 20min, then add pure water and quality Ratio is 3:1 sucrose and histidine, drop into the enzyme reactor that adds penicillin G acylase described in step (1);

[0059] (3) Turn on the stirring and control the stirring speed to 400r / min, control the pH value to 6.8 with 4mol / L ammonia water, and control the temperature to 15°C with a circulating freezer until the conversion rate of 6-APA n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com