Nanoparticle, display substrate preparation method and display device

A nanoparticle and nanoparticle technology, applied in the field of display, can solve the problems of QLED not reaching the mass production level, high resolution, performance impact of nanoparticles, etc., achieve better display performance, improve resolution, and avoid photobleaching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

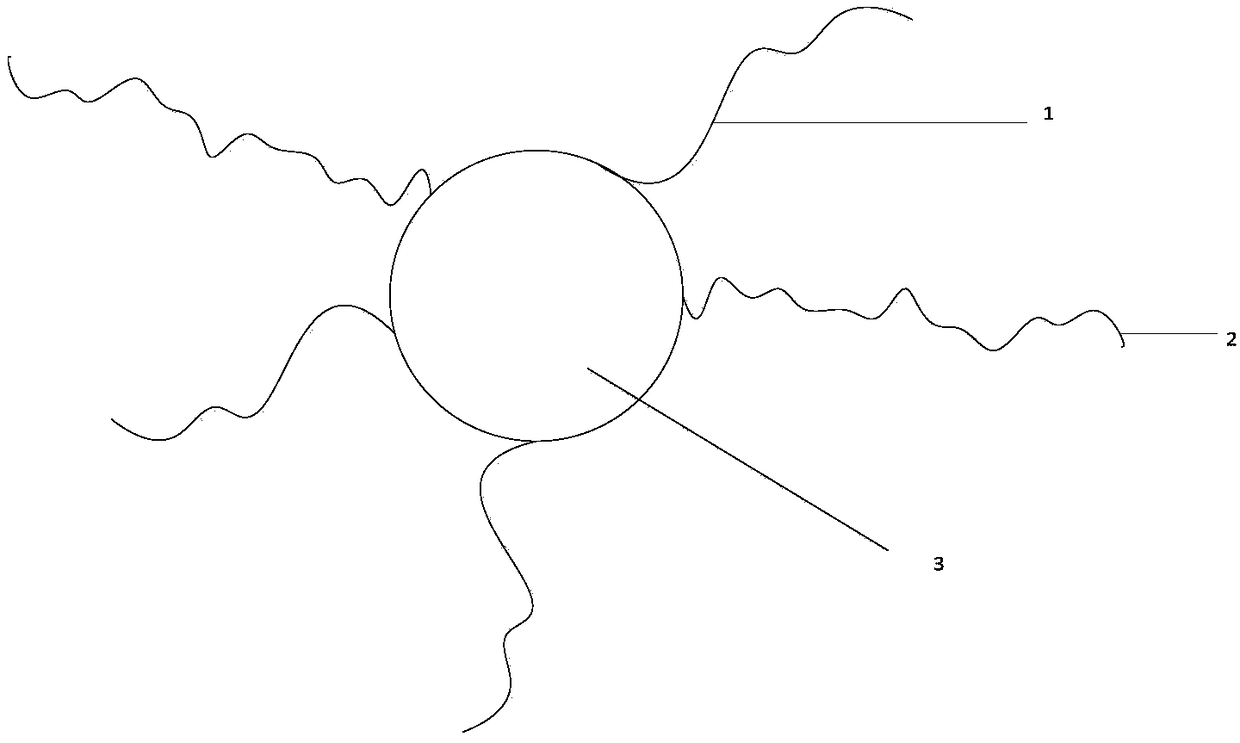

[0039] When the nanoparticles are quantum dots, the preparation method of the quantum dots comprises the following steps:

[0040] S1: contacting the quantum dot raw material with pyridine to obtain the quantum dot with pyridine on the surface;

[0041] S2: Contacting the quantum dots with pyridine on the surface with the first ligand and the second ligand to obtain the quantum dots described in the above technical solution; wherein the first ligand has alkali solubility, and the second ligand is heated Cross-linking can then occur.

[0042] In some embodiments, the S1 is performed as follows:

[0043] The quantum dot raw material and pyridine (as a solvent) are contacted at room temperature and pressure for 5 minutes to 10 hours with stirring at a weight ratio greater than 1:1, and then the quantum dots with pyridine on the surface are separated by centrifugal separation.

[0044] In some embodiments, the quantum dot raw material carries at least one ligand selected from th...

Embodiment 1

[0104] 1. Using CdTe as the core, quantum dots were prepared by ligand exchange method.

[0105] 2. Prepare or purchase CdTe quantum dots whose ligand is trioctyl oxon or oleic acid.

[0106] 3. Add the CdTe quantum dots whose ligand is trioctylphosphine or oleic acid to 100 mL of pyridine, stir for 1 hour, concentrate the solution, and add ethanol to precipitate the quantum dots. Centrifuge and collect the precipitate, at this time the surface ligands of the CdTe quantum dots are replaced by pyridine.

[0107] 4. Redissolve the precipitate in toluene and add excess primary ligand and the second ligand

[0108]The molar ratio of the first ligand to the second ligand is 8:2. After stirring for 1 hour, methanol is added to precipitate the quantum dots whose ligands have been converted into the first ligand and the second ligand structure. The lower precipitate obtained after centrifugation is the desired quantum dot. Quantum dots can be preserved in toluene or n-hexane af...

Embodiment 2

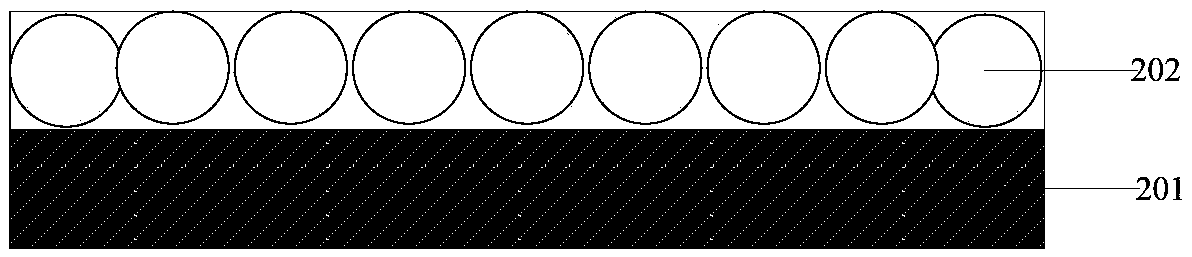

[0110] 1. Spin-coat a layer of 35nm red quantum dots on the substrate.

[0111] 2. Spin-coat photoresist (positive resist) on the red quantum dot layer, and then perform pre-baking and exposure.

[0112] 3. Developing; during the developing process, the exposed positive resist is removed, the quantum dots under it lose the protection of the photoresist, and part of the ligand reacts with an alkaline developer (such as TMAH aqueous solution) to become water-soluble, thereby This part of the red quantum dots is dissolved in the developer and detached from the substrate; the nanoparticles that need to be left are protected by the photoresist and remain on the substrate.

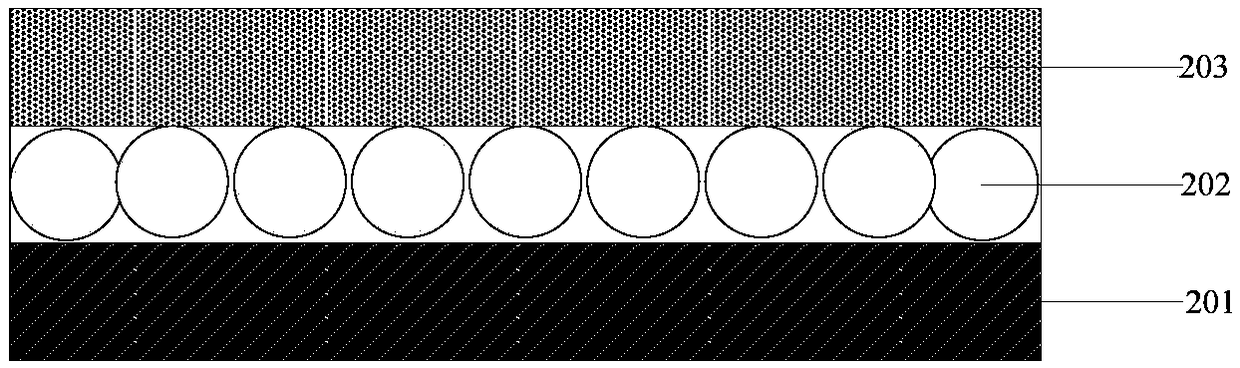

[0113] 4. Post-baking, so that the red quantum dots still protected by the photoresist are thermally cross-linked, thereby fixing the red quantum dots on the substrate.

[0114] 5. Soak in the stripping solution to remove the photoresist to complete the patterning of the red quantum dots.

[0115] 6. Spin-coat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com