Tripod shaped platinum palladium copper alloy catalyst capable of catalyzing oxygen reduction reaction, and preparation method thereof

A tripod and catalyst technology, applied in the field of tripod-shaped platinum-palladium-copper alloy catalyst and preparation thereof, can solve the problems of less reports of platinum-based tripods and the like, and achieve the effects of high yield, mild reaction conditions, outstanding activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

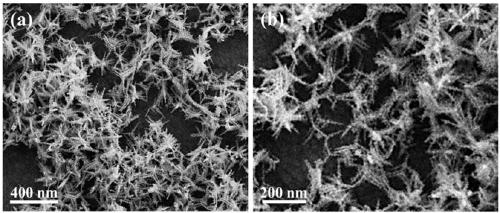

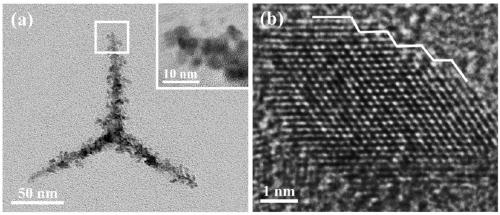

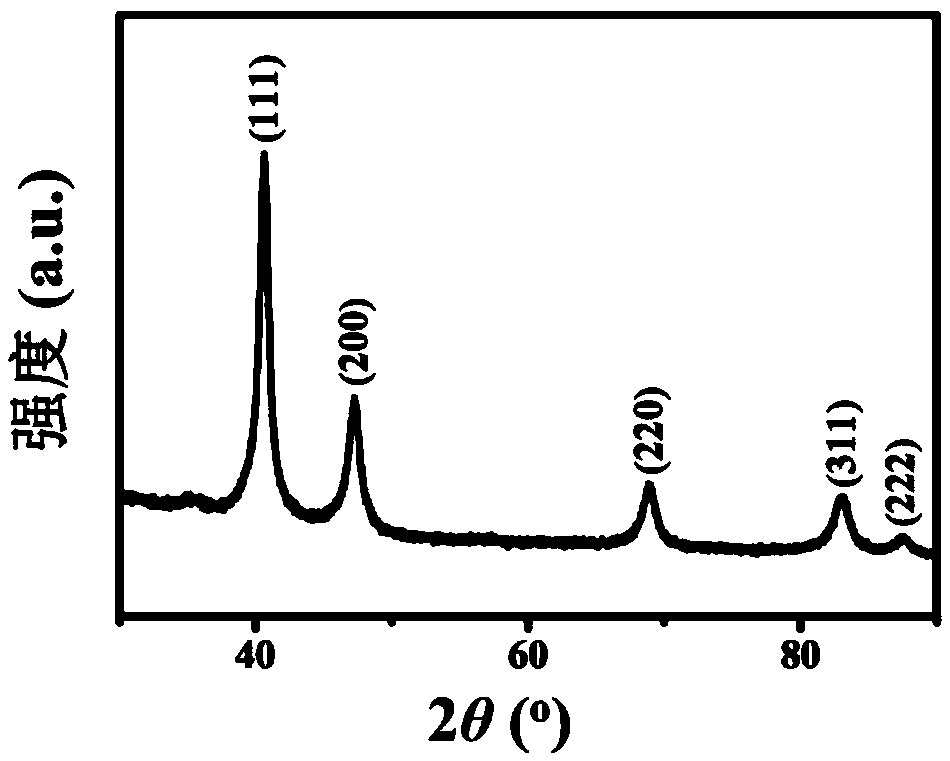

[0041] A preparation method of a tripod-shaped platinum-palladium-copper alloy catalyst for catalyzing oxygen reduction reaction, the method comprises the following steps:

[0042] 1) prepare the sodium chloropalladate, chloroplatinic acid and cupric chloride solution that concentration is 20mM respectively, and concentration is that the hydrochloric acid solution of 6M and the ascorbic acid solution that concentration is 0.1M;

[0043] 2) get 2.5mL sodium chloropalladate, 1mL chloroplatinic acid and 1mL cupric chloride solution and mix respectively, then add 0.2mL hydrochloric acid solution, then add 200mg potassium bromide and 50mg F127, ultrasonically mix; Finally, add 2mL ascorbic acid solution again , ultrasonic mixing for 20 minutes;

[0044] 3) After the solution is fully mixed, it is placed in an oil bath and heated to between 95° C., and after 3 hours of reaction, washed, centrifuged and dried to obtain a platinum-palladium-copper tripod-shaped oxygen reduction cataly...

Embodiment 2

[0048] A preparation method of a tripod-shaped platinum-palladium-copper alloy catalyst for catalyzing oxygen reduction reaction, the method comprises the following steps:

[0049] 1) prepare the sodium chloropalladate, chloroplatinic acid and cupric chloride solution that concentration is 20mM respectively, and concentration is that the hydrochloric acid solution of 6M and the ascorbic acid solution that concentration is 0.1M;

[0050] 2) Take 3 mL of sodium chloropalladate, 0.75 mL of chloroplatinic acid and 0.75 mL of cupric chloride solution and mix, then add 0.2 mL of hydrochloric acid solution, then add 200 mg of potassium bromide and 50 mg of F127, and ultrasonically mix evenly. Finally, 2 mL of ascorbic acid solution was added, and ultrasonically mixed for 20 minutes;

[0051] 3) After the solution is fully mixed, it is heated to 95° C. in an oil bath, and after 3 hours of reaction, washed, centrifuged and dried to obtain the platinum-palladium-copper multi-branched na...

Embodiment 3

[0055] A preparation method of a tripod-shaped platinum-palladium-copper alloy catalyst for catalyzing oxygen reduction reaction, the method comprises the following steps:

[0056] 1) prepare the sodium chloropalladate, chloroplatinic acid and cupric chloride solution that concentration is 20mM respectively, and concentration is that the hydrochloric acid solution of 6M and the ascorbic acid solution that concentration is 0.1M;

[0057] 2) 1.5 mL of sodium chloropalladate, 1.5 mL of chloroplatinic acid and 1.5 mL of cupric chloride solution were respectively mixed, then 0.2 mL of hydrochloric acid solution was added, 200 mg of potassium bromide and 50 mg of F127 were added, and ultrasonically mixed uniformly. Finally, 2 mL of ascorbic acid solution was added, and ultrasonically mixed for 20 minutes;

[0058] 3) After the solution is fully mixed, it is placed in an oil bath and heated to 95° C. After 3 hours of reaction, washed, centrifuged and dried to obtain the platinum-pall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com