Carbon nitride powder preparation method, and carbon nitride quantum dots and preparation method thereof

A technology of carbon nitride and quantum dots, applied in chemical instruments and methods, nitrogen compounds, nitrogen and non-metallic compounds, etc., can solve the problems of low quantum yield, achieve good water solubility, stable optical properties, and expand application fields Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] An embodiment of the present invention provides a method for preparing carbon nitride powder, the carbon nitride quantum dots are carbon nitride quantum dots, and the preparation method includes the following steps:

[0018] S01. Provide a cyanamide compound and a phenyl modifier, add the cyanamide compound and the phenyl modifier to the first solvent and mix them, and mix them at 50-90°C to obtain an emulsion; Centrifuge to obtain precursor powder;

[0019] S02. Calcining the precursor powder at 350-600° C. for 1-3 hours under an inert gas flow condition to obtain carbon nitride powder.

[0020] Further, the embodiment of the present invention provides a method for preparing carbon nitride quantum dots. After the carbon nitride powder is prepared by using the method for preparing carbon nitride powder including the steps S01 and S02, the steps further include:

[0021] S03. adding the carbon nitride powder into a second solvent, ultrasonically peeling off the carbon n...

Embodiment 1

[0044] A preparation method of carbon nitride quantum dots, the carbon nitride quantum dots are carbon nitride quantum dots, the preparation method comprising the following steps:

[0045] S11. Add 2.52g of melamine and 3.74g of benzoguanamine into a 250mL three-necked flask, add 100mL of deionized water and heat to 60°C, stir at 1000rpm for 12h, cool to obtain a milky reaction solution. The reaction solution was centrifuged at 5000 rpm for 10 min to obtain a white substance. After repeated washing with deionized water and centrifugation twice, the white substance was transferred to a vacuum oven at 60° C. to obtain a precursor powder.

[0046] S12. Put the above precursor powder in a tubular muffle furnace, raise the temperature to 450° C. and keep the temperature constant for 2 hours under the condition of nitrogen flow, the nitrogen flow rate is 100 mL / min, and obtain light yellow carbon nitride powder material after cooling. Wherein, the heating rate of the muffle furnace ...

Embodiment 2

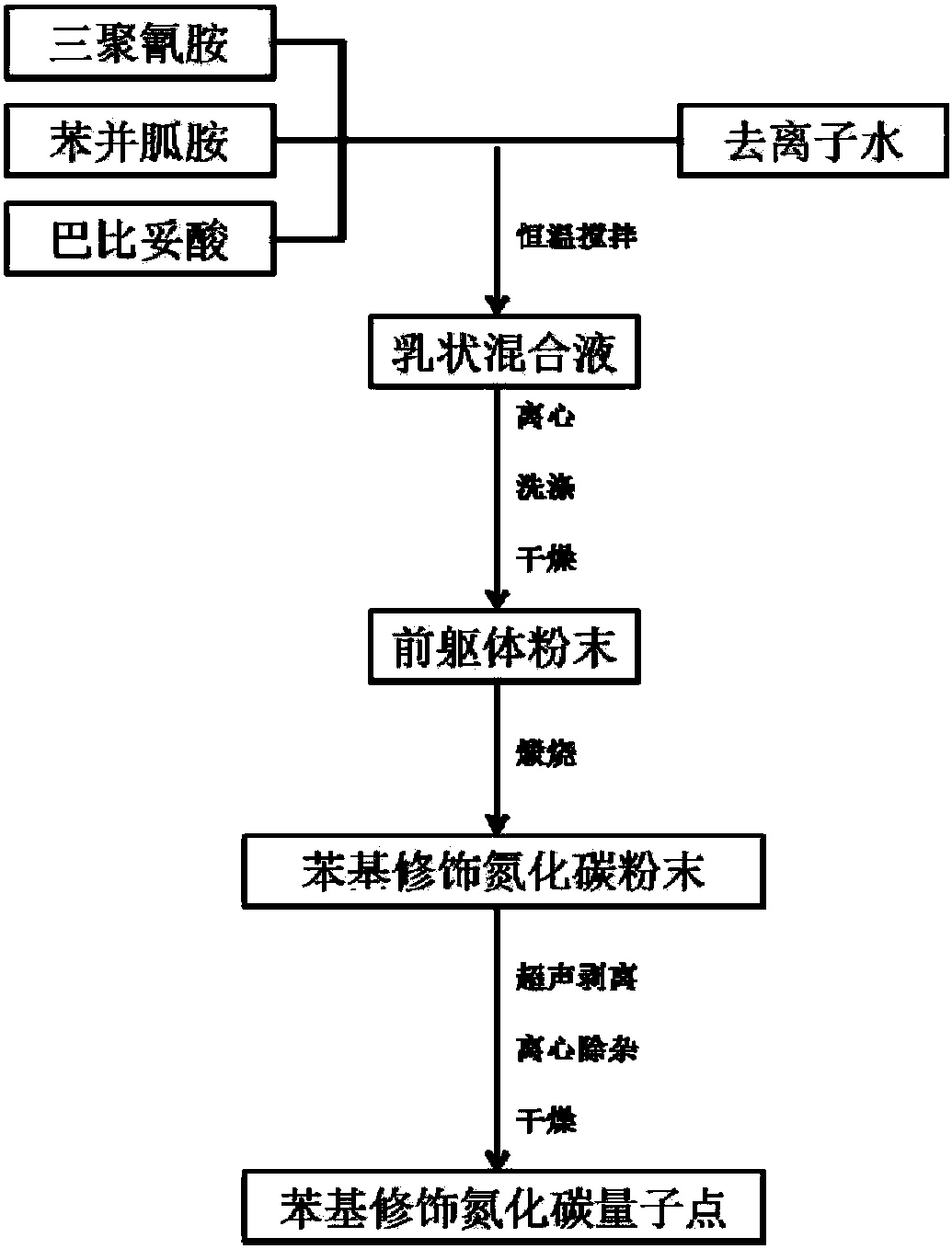

[0050] A kind of preparation method of carbon nitride quantum dot, described carbon nitride quantum dot is carbon nitride quantum dot, and its preparation method comprises the following steps, and its flow chart is as follows figure 1 Shown:

[0051] S21. Add 2.52g of melamine, 3.74g of benzoguanamine, and 1.26g of barbituric acid into a 250mL three-necked flask, add 100mL of deionized water and heat to 60°C, stir at 1000rpm for 12h, cool to obtain a milky reaction solution. The reaction solution was centrifuged at 5000 rpm for 10 min to obtain a white substance. After repeated washing with deionized water and centrifugation twice, the white substance was transferred to a vacuum oven at 60° C. to obtain a precursor powder.

[0052] S22. Put the above precursor powder in a tubular muffle furnace, raise the temperature to 450° C. and keep the temperature constant for 2 hours under the condition of nitrogen flow, the nitrogen flow rate is 100 mL / min, and obtain light yellow carbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com