Method for modifying, separating and purifying protein and method for regulating enzyme activity of sulfhydryl protease

A technology for the separation and purification of thiol proteases, which is applied to the preparation methods of peptides, chemical instruments and methods, animal/human proteins, etc., which can solve the problems of troublesome operation and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

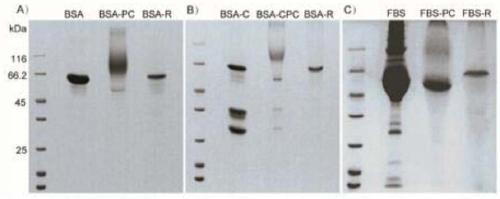

[0037] Example 1 Modification and separation and purification of protein

[0038] 1. Protein-polymer preparation (protein modification)

[0039] 1 Reduced sulfhydryl groups on the surface of TCEP protein

[0040] 1) Dissolve 80mg of BSA and 11mg of TCEP in 10mL of acetic acid buffer at a molar ratio of 1:1, respectively, and connect to a nitrogen deoxygenation device for deoxygenation for 7 minutes; obtain TCEP solution and protein solution respectively;

[0041] 2) Slowly add TCEP to the protein solution and react with magnetic stirring for 7 minutes under the condition of nitrogen deoxygenation. Phosphate buffer was used twice, and a nitrogen deoxygenation device was connected throughout the dialysis process. After the dialysis, the liquid in the dialysis bag was collected, that is, dialysate A.

[0042] 2 Initiator for protein surface sulfhydryl modification

[0043] 1) Take 10mL dialysate A and add it to a weighing bottle of appropriate size, add 2mL Buffer 8.2 and adju...

Embodiment 2

[0056] Example 2 Enzyme activity regulation of thiol protease

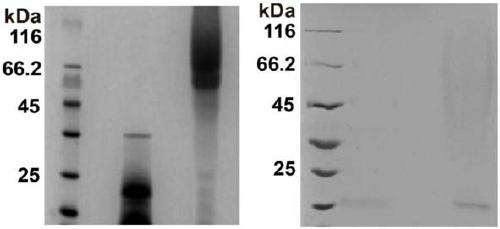

[0057] 1. Enzyme activity inhibition of thiol protease

[0058] 1 Reduced sulfhydryl groups on the surface of TCEP protein

[0059] 1) Dissolve 80mg of thiol protease protein (Bromelain and Papain were used as examples in this example) and 11mg of TCEP in 10mL of acetic acid buffer at a molar ratio of 1:1, respectively, and connect to a nitrogen deoxygenation device to remove Oxygen for 7min; obtain protease solution and TCEP solution respectively;

[0060] 2) Slowly add the TCEP solution to the protein solution dropwise, and react with magnetic stirring for 7 minutes under the condition of nitrogen deoxygenation. After the reaction, transfer the mixed solution into a dialysis bag, put the dialysis bag into the buffer solution and dialyze three times, and use acetate buffer solution for the first time. Phosphate buffer was used for the last two times, and the nitrogen deoxygenation device was connected to the wh...

Embodiment 3

[0074] Papain and bromelain were used to protect the activity of thiol proteases by polymers, and four different treatment methods were used to compare the enzyme activities.

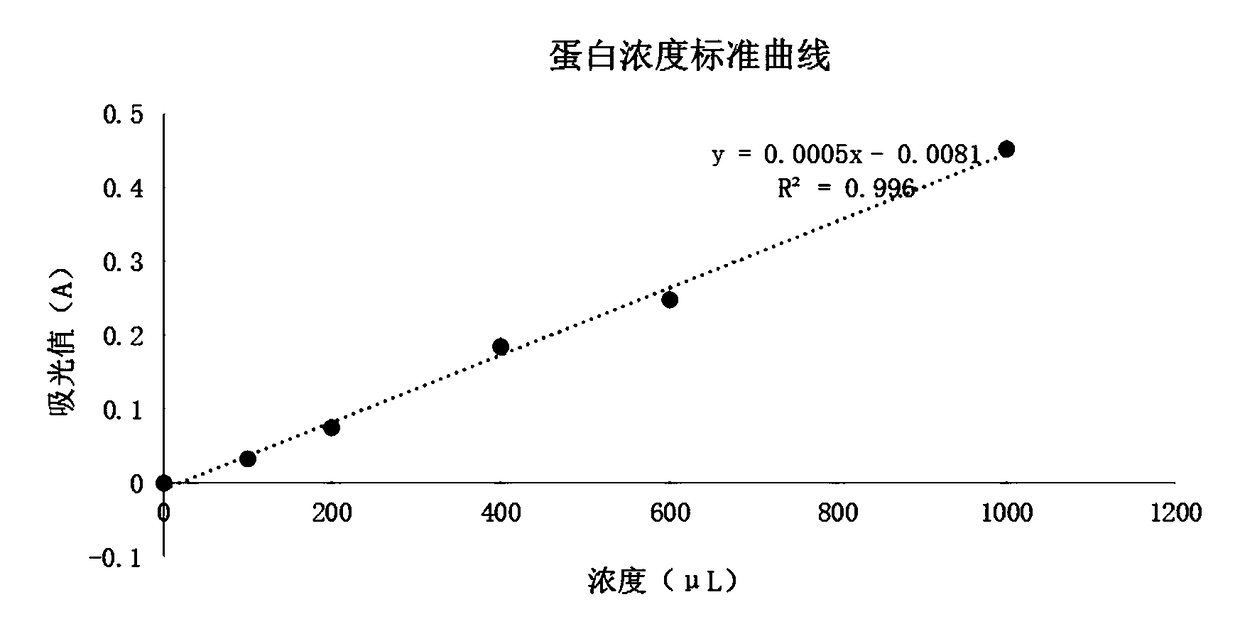

[0075] according to image 3 Determine the concentration of Papain, Papain-NIPAM polymer, Bromelain and Bromelain-NIPAM polymer with the standard curve of protein concentration, and adjust the concentration to 0.1mg / mL to measure the enzyme activity, because the absorbance value of casein at this concentration is measured in the ultraviolet Within the appropriate range that can be measured by a spectrophotometer.

[0076] 1) The four processing methods are as follows:

[0077]Papain, Papain-NIPAM polymers and bromelain, Bromelain-NIPAM polymers are treated in the same way, and papain is taken as an example below.

[0078] a) pH2.0 treatment

[0079] Considering factors such as sample size, experimental error, and convenient pH adjustment, each take a certain amount of Papain and Papain-NIPAM polymer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com