A kind of preparation method of dry method and wet method carbon-coated high nickel ternary positive electrode material

A positive electrode material and carbon coating technology, which is applied in the field of preparation of dry and wet carbon coated high-nickel ternary positive electrode materials, to achieve the effects of improving Coulombic efficiency, less waste of raw materials, and improving conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

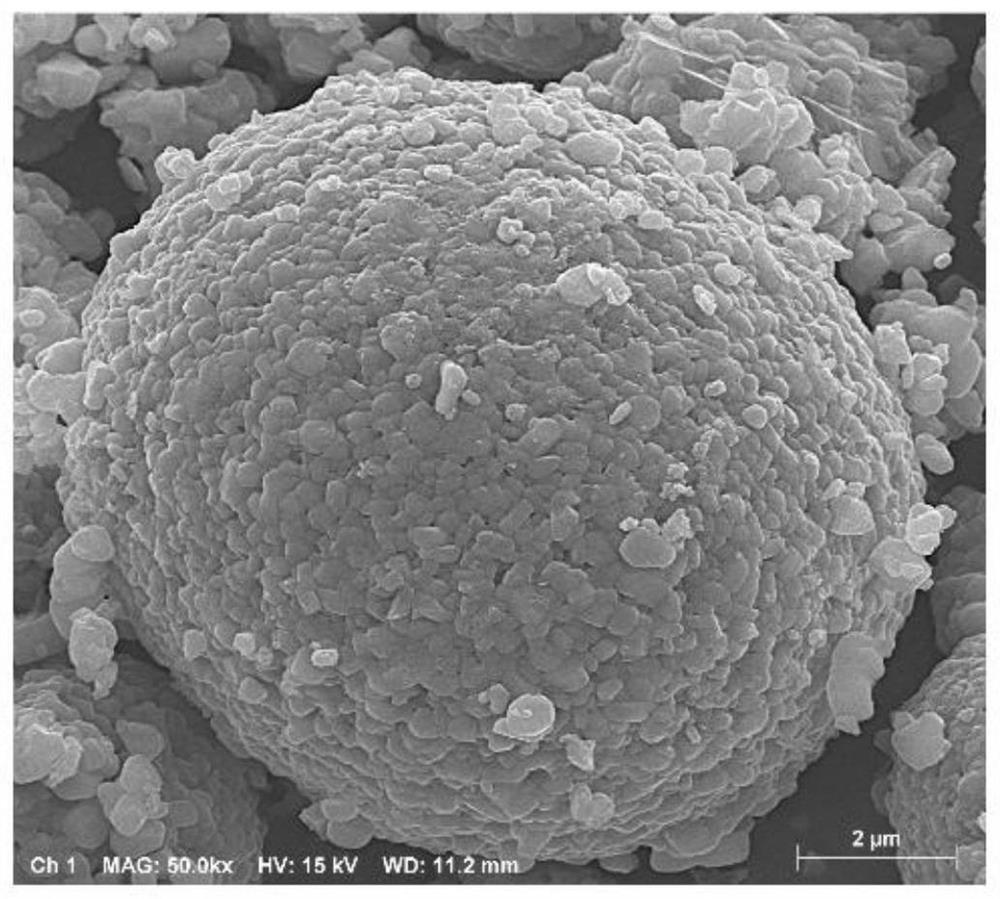

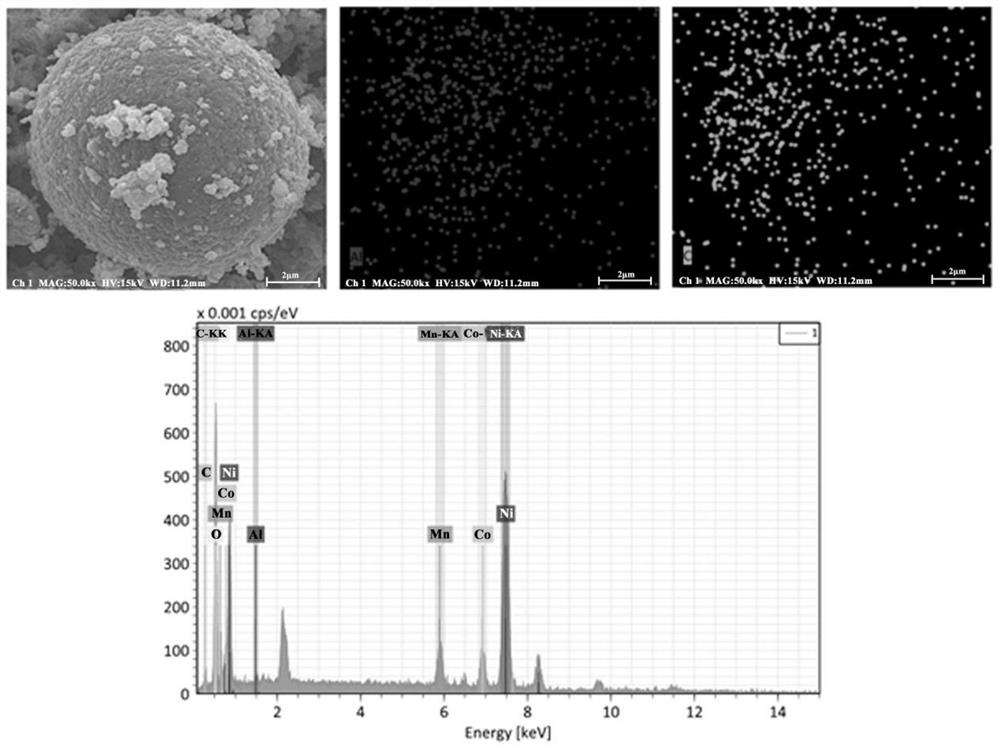

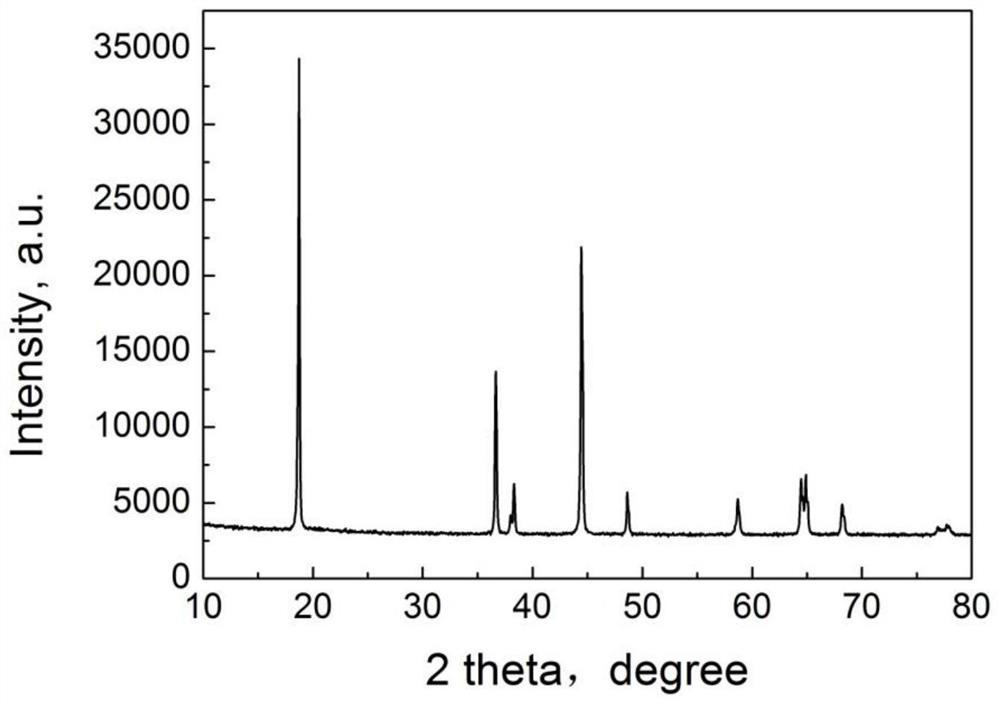

Embodiment 1

[0031] The sintered high-nickel ternary cathode material NCM811 (nickel content greater than or equal to 47 wt.%) was pulverized, classified, and then the particle size D50 was 5-30nm in the coating agent conductive carbon black and graphene oxide mixture (graphene oxide accounted for 3% of the total amount of the mixture) is dispersed in a water solvent, the ternary positive electrode material is added to the aqueous solution containing the coating agent and mixed, fully stirred, the stirring speed is 20 rpm, and then the mixed slurry is heated at 80 °C in a vacuum for 8 hours, and the The water content is evaporated to dryness, and the mixed and dried materials are fused with a high-speed fusion machine. The fusion machine rotates at 800 rpm and the fusion time is 15 minutes. Then, the finished product is obtained after sieving, batch mixing, and demagnetization.

Embodiment 2

[0033] The sintered high-nickel ternary cathode material NCM811 (nickel content greater than or equal to 47 wt.%) was pulverized, classified, and then the particle size D50 was 5-30nm in the coating agent conductive carbon black and graphene oxide mixture (graphene oxide accounted for 3% of the total amount of the mixture) was dispersed in a water solvent, the ternary positive electrode material was added to the aqueous solution containing the coating agent and mixed, fully stirred, and the stirring speed was 40 rpm, and then the mixed slurry was heated at 150 °C in a vacuum for 2 hours. The water content is evaporated to dryness, and the mixed and dried materials are fused with a high-speed fusion machine. The fusion machine rotates at 1500 rpm and the fusion time is 8 minutes. Then, the finished product is obtained after sieving, batch mixing, and demagnetization.

Embodiment 3

[0035] The sintered high-nickel ternary cathode material NCM811 (nickel content greater than or equal to 47 wt.%) was pulverized, classified, and then the particle size D50 was 5-30nm in the coating agent conductive carbon black and graphene oxide mixture (graphene oxide accounted for 3% of the total amount of the mixture) was dispersed in a water solvent, the ternary positive electrode material was added to the aqueous solution containing the coating agent and mixed, fully stirred, and the stirring speed was 30 rpm, and then the mixed slurry was heated at 120 °C in a vacuum for 5 hours. The water content is evaporated to dryness, and the mixed and dried materials are fused with a high-speed fusion machine. The fusion machine rotates at 1200 rpm and the fusion time is 12 minutes. Then, the finished product is obtained after sieving, batch mixing, and demagnetization.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com