A manufacturing process for high-speed rail track slabs

A manufacturing process and track slab technology, which is applied in the field of high-speed rail track slab manufacturing technology, can solve problems such as increased rigidity and reduced toughness, and achieve the effects of improved bonding, low material consumption, and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

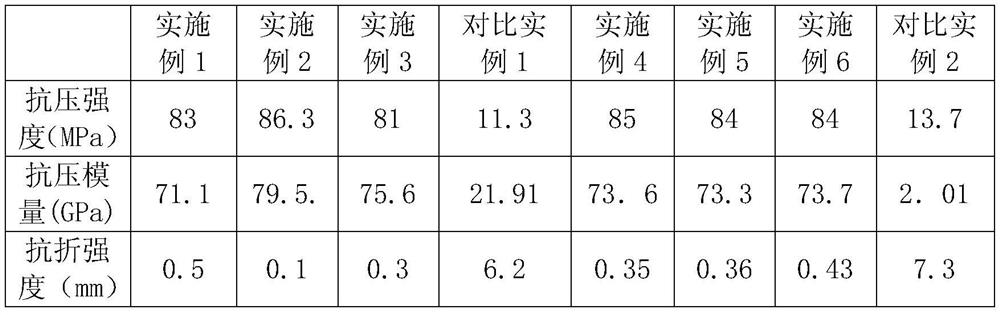

Examples

Embodiment 1

[0042] The manufacture of high-speed rail track slabs adopts the following processes:

[0043] The untwisted basalt long fiber is input from the front of the boat-shaped container filled with 207 epoxy resin, dibutyl ester, 2,4,6-trimethylbenzoyl phosphonic acid ethyl ester and acetone mixed solution, and mixed with epoxy resin After solution impregnation, the basalt fibers output from the tail end of the ship-shaped container are woven into 128 fiber threads through a twisting machine; then they are input into a basalt fiber rope weaving machine to be woven into a basalt fiber rope with a diameter of 6mm; The basalt fiber rope net with a width of 36×36mm and a width of 2.46m is ready for use; the mass ratio of the mixed solution of 207 epoxy resin, dibutyl ester, 2,4,6-trimethylbenzoylphosphonic acid ethyl ester and acetone 100:8:0.3:6;

[0044] Mix 207 epoxy resin, dibutyl ester, ethyl 2,4,6-trimethylbenzoyl phosphonate, acetone, P042.5R cement, and 0.3mm quartz sand at a r...

Embodiment 2

[0051] The manufacture of high-speed rail track slabs adopts the following processes:

[0052] The untwisted basalt long fiber is input from the front of the boat-shaped container filled with 207 epoxy resin, dibutyl ester, 2,4,6-trimethylbenzoyl phosphonic acid ethyl ester and acetone mixed solution, and mixed with epoxy resin After solution impregnation, the basalt fibers output from the tail end of the ship-shaped container are woven into 128 fiber threads through a twisting machine; then they are input into a basalt fiber rope weaving machine to be woven into a basalt fiber rope with a diameter of 6mm; The basalt fiber rope net with a width of 36×36mm and a width of 2.46m is ready for use; the mass ratio of the mixed solution of 207 epoxy resin, dibutyl ester, 2,4,6-trimethylbenzoylphosphonic acid ethyl ester and acetone 100:13:6:11;

[0053] Mix 207 epoxy resin, dibutyl ester, ethyl 2,4,6-trimethylbenzoyl phosphonate, acetone, P042.5R cement, and 1.0mm quartz sand at a r...

Embodiment 3

[0060] The manufacture of high-speed rail track slabs adopts the following processes:

[0061] The untwisted basalt long fiber is input from the front of the boat-shaped container filled with 207 epoxy resin, dibutyl ester, 2,4,6-trimethylbenzoyl phosphonic acid ethyl ester and acetone mixed solution, and mixed with epoxy resin After solution impregnation, the basalt fibers output from the tail end of the ship-shaped container are woven into 128 fiber threads through a twisting machine; then they are input into a basalt fiber rope weaving machine to be woven into a basalt fiber rope with a diameter of 6mm; The basalt fiber rope net with a size of 36×36mm and a width of 2.46m is ready for use; the mass of the mixed solution of 207 epoxy resin, dibutyl ester, 2,4,6-trimethylbenzoylphosphonic acid ethyl ester and acetone The ratio is 100:9:0.8:7;

[0062] Mix 207 epoxy resin, dibutyl ester, ethyl 2,4,6-trimethylbenzoyl phosphonate, acetone, P042.5R cement, and 0.4mm quartz sand ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com