Preparation method of ultra-high graft density polymer molecular brush

A graft density and polymer technology is applied in the field of preparation of ultra-high graft density polymer molecular brushes, and can solve the problems of difficult preparation of ultra-high graft density polymer molecular brushes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The invention provides a kind of preparation method of ultra-high grafting density polymer molecular brush, comprises the following steps:

[0034] (1) Immerse the monocrystalline silicon wafer in the mixed solution of concentrated sulfuric acid and aqueous hydrogen peroxide solution, heat treatment, and then wash and dry the heated monocrystalline silicon wafer sequentially to obtain SiO 2 / Si substrate;

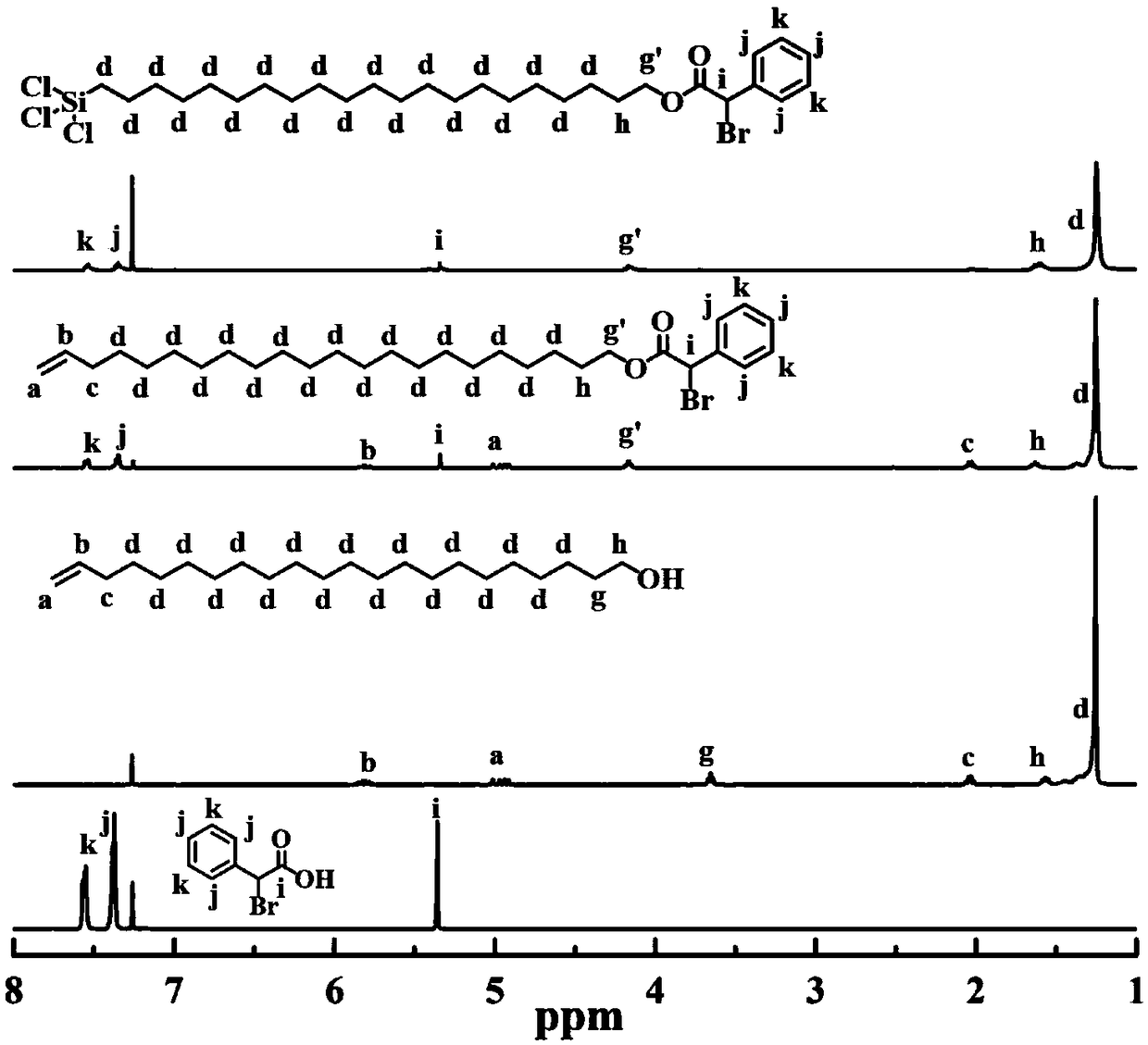

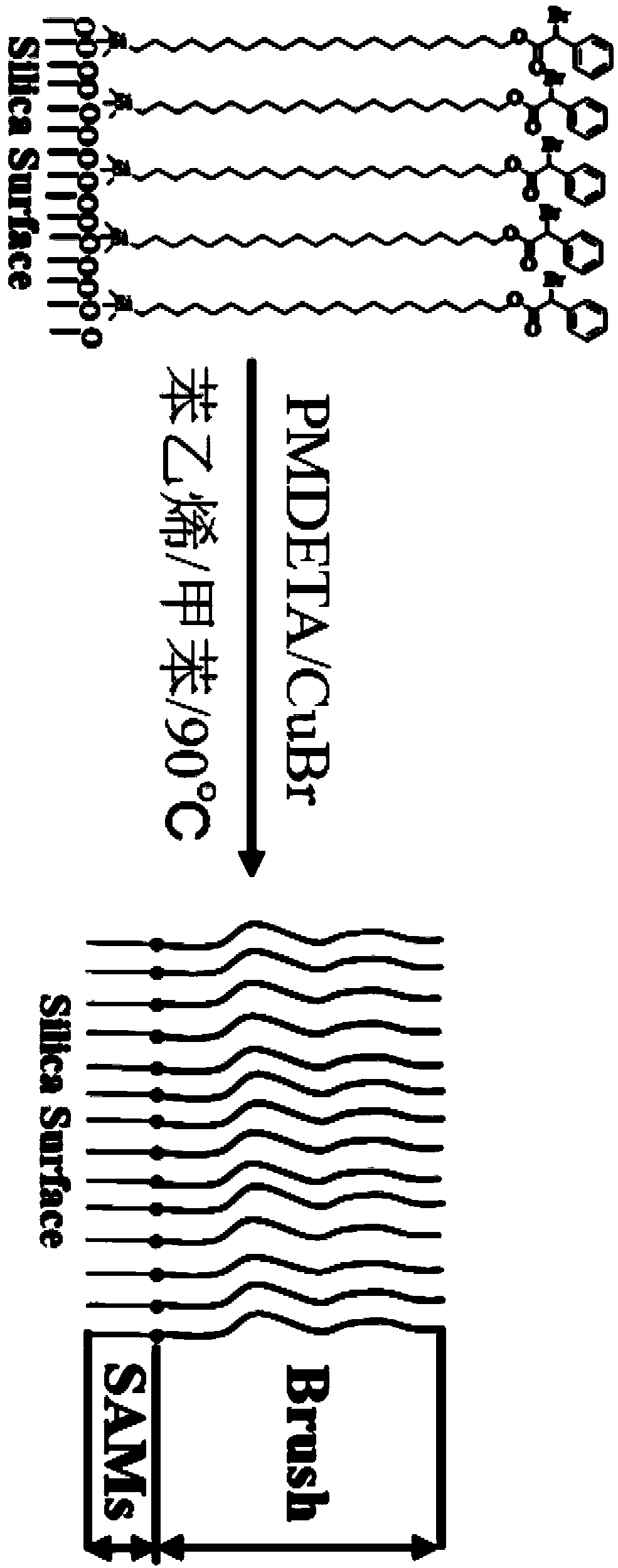

[0035] (2) the SiO that described step (1) obtains 2 / The Si substrate is immersed in the initiator solution and subjected to static treatment to obtain the initiator-functionalized SiO 2 / Si substrate; The initiator is 22-(trichlorosilyl) docosyl-2-bromo-2-phenylacetate;

[0036] (3) under nitrogen protection, the initiator functionalized SiO that described step (2) obtains 2 / Si substrate, cuprous bromide, styrene, pentamethyldiethyltriamine and toluene are mixed and then heat-treated to obtain ultra-high graft density polymer molecular brushes.

[0037] In th...

Embodiment 1

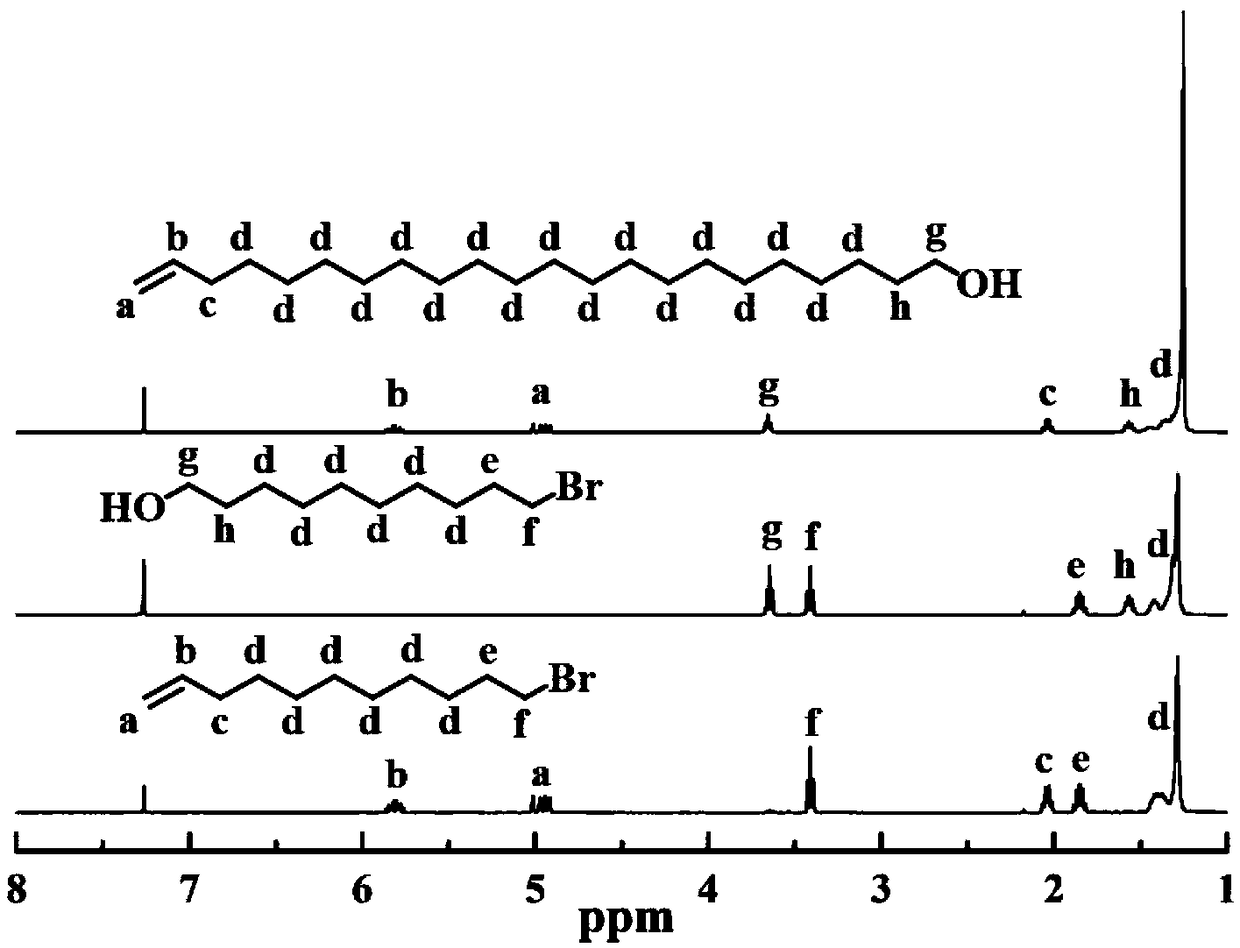

[0102] Synthesis of 21-dodecen-1-ol: Add magnesium chips (1.68g, 70mM) and freshly distilled tetrahydrofuran (2mL) to a 250mL three-necked flask under nitrogen atmosphere, add a few drops of 1,2-dibromo Ethane activates magnesium chips. Then, a solution of 1-bromo-undecene (11.65 g, 0.05 mol) in freshly distilled tetrahydrofuran (50 mL) was added dropwise, and moderate reflux was controlled after a few minutes, and the temperature in the three-necked flask did not exceed 55°C. After the dropwise addition, the reaction mixture was heated at 50°C for 2 hours, then cooled to -78°C, and maintained at this temperature for 20 minutes, purified CuI (0.38g, 2mM) was added under nitrogen flow, and the mixture was heated at -78°C Leave on for 10 minutes. Then, slowly warm up to 0°C until dark purple appears, immediately cool to -78°C and add protected alcohol solution (10.28g, 0.04mol, in 50mL THF), (protected alcohol solution consists of 0.04mol 11-bromo-1 - undecanol, 0.04mol methyl...

Embodiment 2

[0112] The test was carried out according to the method of Example 1, with the difference that in the preparation process of the polymer molecular brush, the heating time in the oil bath was adjusted to 130 minutes to obtain a polystyrene molecular brush.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com