Modified polyurethane bonding agent and preparation method thereof

A polyurethane and adhesive technology, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problem of insufficient long post-adhesive time, short interval between initial adhesive and surface-drying, unfavorable film High thixotropy, guaranteed thixotropy, and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A modified polyurethane binder, which includes A component and B component,

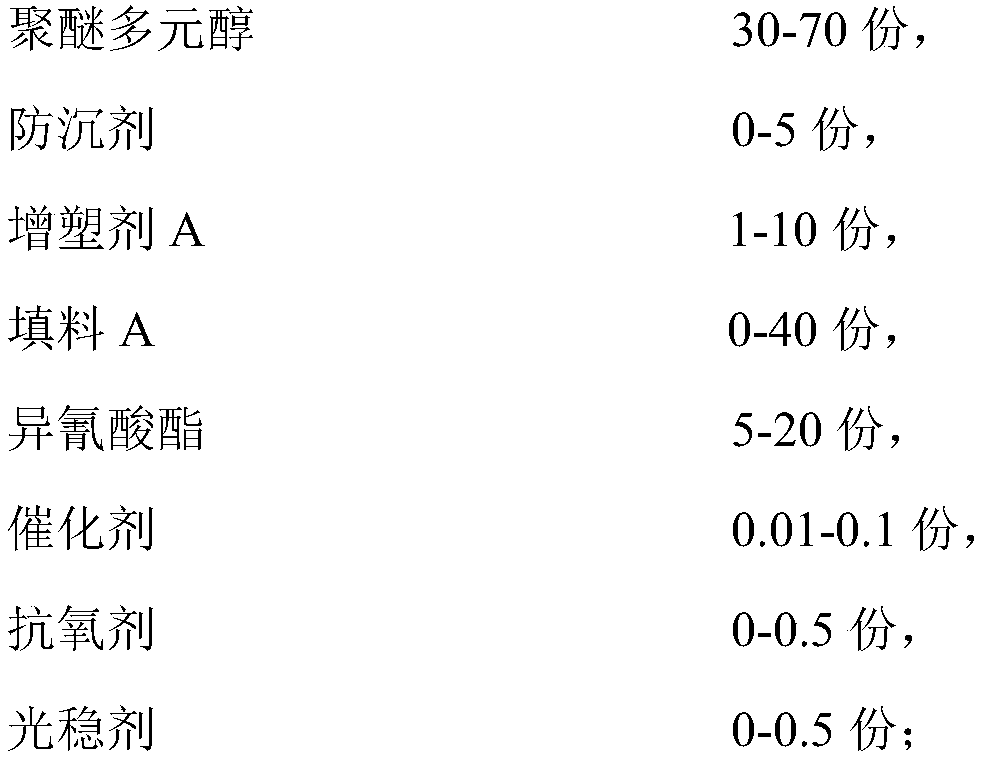

[0052] In parts by mass, the A component includes the following raw material components:

[0053]

[0054]Preparation of component A: Put the weighed DL-1000D, EP-330N, DL-2000D, fumed silica, plasticizer T-50 and calcium carbonate (400 mesh) into the reaction bottle, stir and heat up for 110- 115°C, vacuum-0.095-0.1Mpa dehydration for 1.5-2 hours, moisture requirement ≤ 200ppm, cool down to 65-70°C, add isocyanate to keep it warm for 2 hours, then add organotin catalyst to keep warm for 2 hours, then cool down to 60°C, Add Antioxidant-264 and Light Stabilizer UV-9, cool down and stir for 15 minutes, then discharge and pack below 50°C.

[0055] In parts by mass, the B component includes the following raw material components:

[0056]

[0057]

[0058] Preparation of component B: First put the weighed chlorinated palm oil methyl ester into the dispersion tank, then put the pre-mixed ...

Embodiment 2

[0061] A modified polyurethane binder, which includes A component and B component,

[0062] In parts by mass, the A component includes the following raw material components:

[0063]

[0064] Preparation of component A: Put the weighed DL-1000D, EP-330N, DL-2000D, fumed silica, plasticizer T-50 and calcium carbonate (400 mesh) into the reaction bottle, stir and heat up for 110- 115°C, vacuum-0.095-0.1Mpa dehydration for 1.5-2 hours, moisture requirement ≤ 200ppm, cool down to 65-70°C, add isocyanate to keep it warm for 2 hours, then add organotin catalyst to keep warm for 2 hours, then cool down to 60°C, Add Antioxidant-264 and Light Stabilizer UV-9, cool down and stir for 15 minutes, then discharge and pack below 50°C.

[0065] In parts by mass, the B component includes the following raw material components:

[0066]

[0067]

[0068] Preparation of component B: First put the weighed chlorinated palm oil methyl ester into the dispersion tank, then put the pre-mixed...

Embodiment 3

[0071] A modified polyurethane binder, which includes A component and B component,

[0072] In parts by mass, the A component includes the following raw material components:

[0073]

[0074] Preparation of component A: Put the weighed DL-1000D, EP-330N, DL-2000D, fumed silica, plasticizer T-50 and calcium carbonate (400 mesh) into the reaction bottle, stir and heat up for 110- 115°C, vacuum-0.095-0.1Mpa dehydration for 1.5-2 hours, moisture requirement ≤ 200ppm, cool down to 65-70°C, add isocyanate to keep it warm for 2 hours, then add organotin catalyst to keep warm for 2 hours, then cool down to 60°C, Add Antioxidant-264 and Light Stabilizer UV-9, cool down and stir for 15 minutes, then discharge and pack below 50°C.

[0075] In parts by mass, the B component includes the following raw material components:

[0076]

[0077]

[0078] Preparation of component B: First put the weighed chlorinated palm oil methyl ester into the dispersion tank, then put the pre-mixed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com