A kind of asphalt glue and its preparation method and application

A technology of asphalt glue and petroleum asphalt, which is applied in the field of asphalt glue and its preparation, can solve problems affecting the service life of waterproof membranes, peeling of glue layers and sheets, hidden dangers of waterproofing projects, etc., to improve multiple performance indicators and improve durability. Poor aging resistance and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

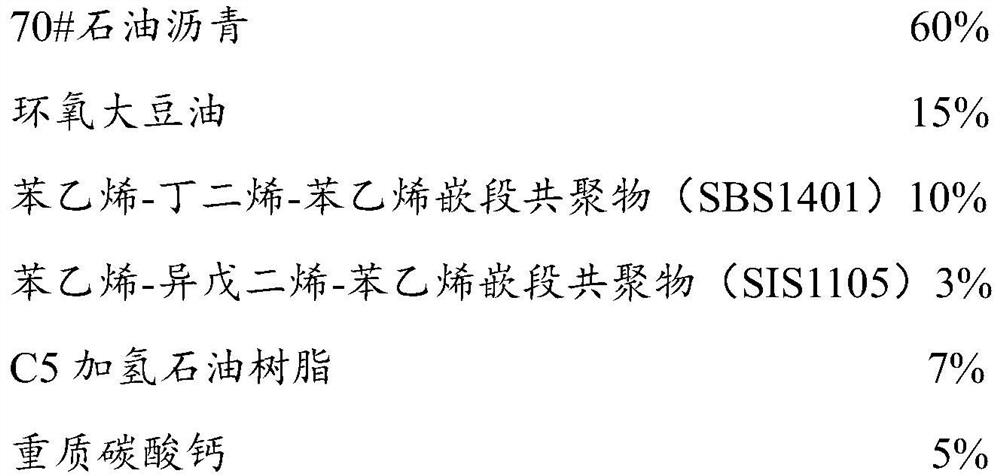

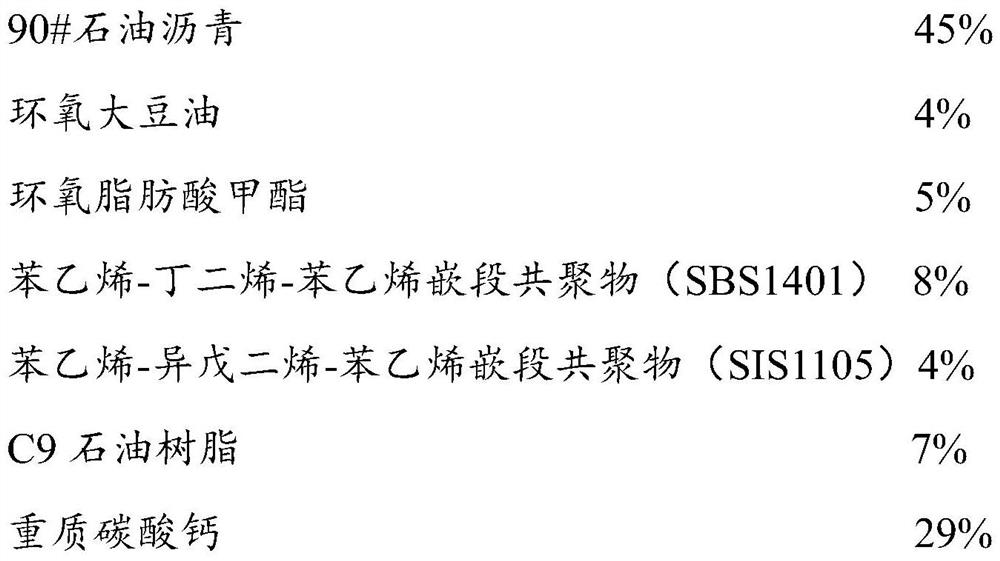

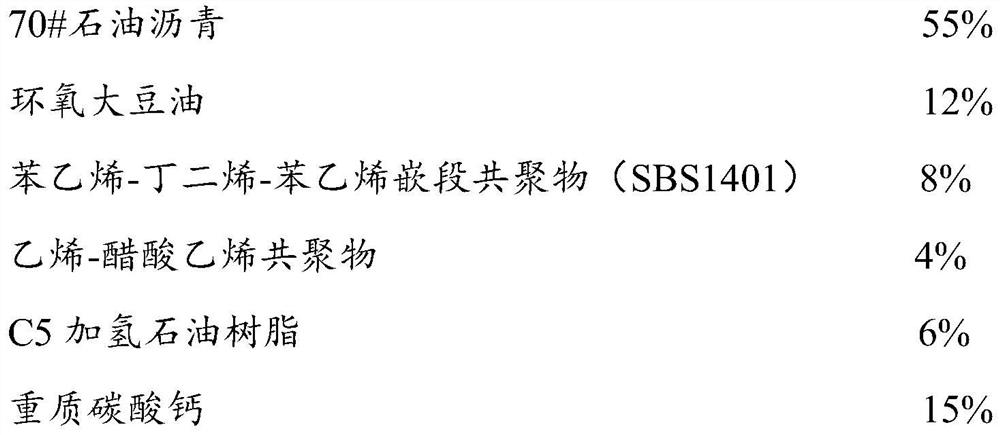

Method used

Image

Examples

preparation example Construction

[0040]The present invention also includes the preparation method of above-mentioned asphalt glue, comprises the following steps:

[0041] S1. Add the petroleum pitch and epoxy plasticizer into the reaction kettle, stir and heat to 90-160°C;

[0042] S2, add tackifying resin again, after stirring for 30-60min, heat up to 180-185°C;

[0043] S3. Add styrene-butadiene-styrene block copolymer and hot-melt adhesive elastomer and keep warm at 180-185°C for 60-240min at high speed;

[0044] S4. Add inorganic filler, lower the temperature to 160-170° C. and stir for 30-60 minutes.

[0045] From the above description, it can be known that the beneficial effects of the present invention are: the preparation process of the present invention is simple, the operation is convenient, and there is no volatile substance in the whole process, which causes little harm to the operator, and the operation is more economical.

[0046] The present invention also includes the application of the abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com