Iron-based porous material for degrading azo dye and preparation method of iron-based porous material

A technology of porous materials and azo dyes, used in chemical instruments and methods, manufacturing tools, water pollutants, etc., can solve the problems of poor self-stability, increased preparation cost, physiological toxicity, etc., and achieves good conductivity and low price. , Easy to operate and controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

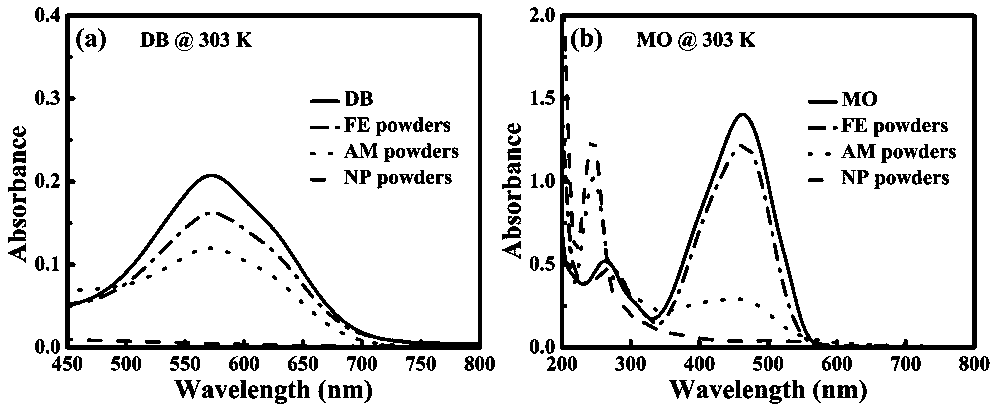

Examples

Embodiment 1

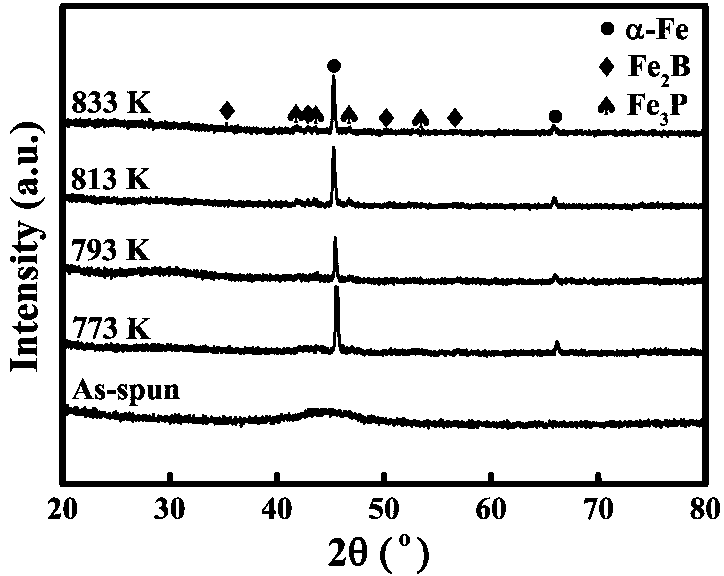

[0018] (1) Fe 76 Si 9 B 10 P 5 As the initial alloy composition, the raw material purity required for the initial alloy is 99.98% Fe, 99.998% Si, 99.5% B and alloy 99.5% Fe 3 The mixture composed of P is put into a crucible, and the crucible is put into a melting furnace. First, vacuumize the furnace chamber so that the vacuum inside the furnace chamber is 5*10 -3 Pa, and then filled with argon, so as to ensure that the melting of the alloy can be carried out uniformly in the atmosphere protection of the inert gas. In order to ensure that the alloy can be mixed evenly, each alloy ingot is repeatedly smelted 3 to 4 times.

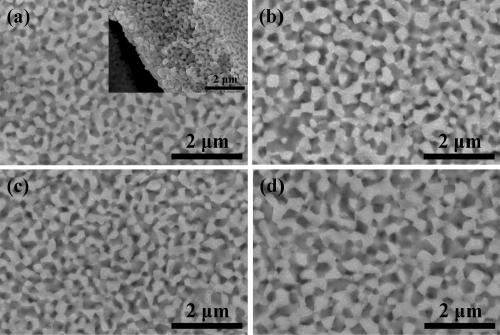

[0019] (2) Put the smelted master alloy into the quartz tube, put the quartz tube into the belt throwing equipment, melt the alloy through induction heating, and finally use high-pressure argon to spray the molten alloy onto the high-speed rotating copper roller , forming Fe with a thickness of 20 μm and a width of 5 mm 76 Si 9 B 10 P 5 Amorphous ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com