Moisture-proof packaging paper material and preparation method thereof

A technology of packaging paper and slurry, which is applied in paper coating, papermaking, textiles and papermaking, etc., can solve the problems of poor moisture-proof protection performance, and achieve the effects of good bonding fastness, wide application prospect and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

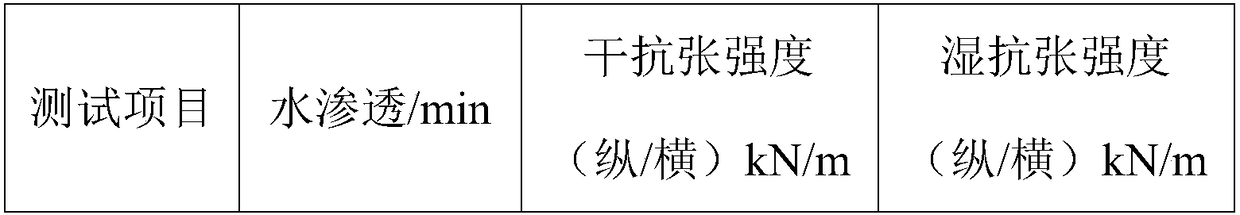

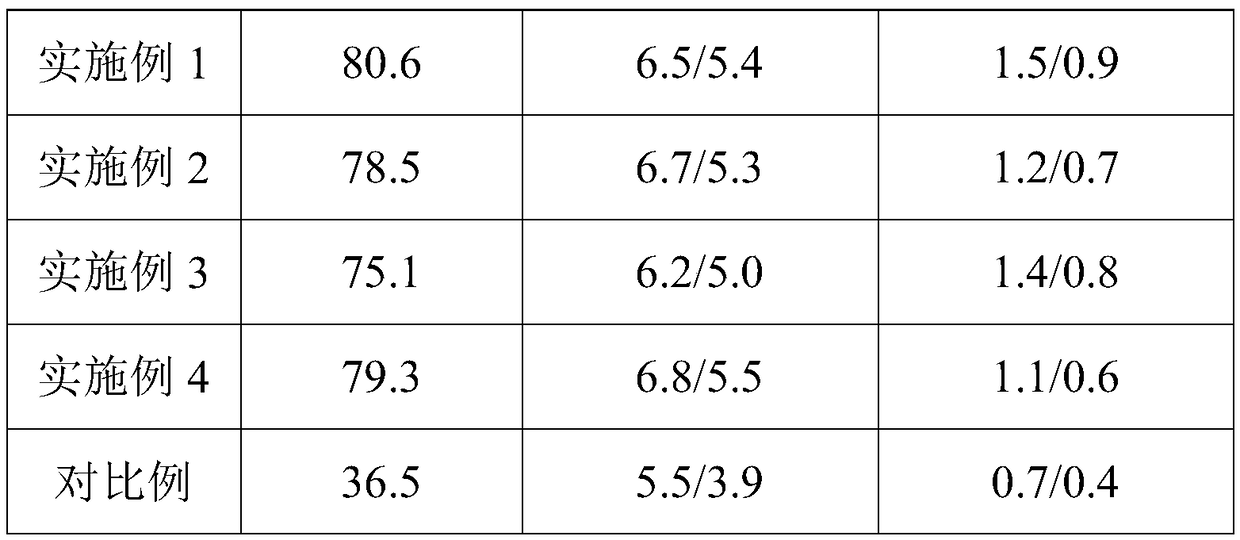

Examples

Embodiment 1

[0018] A moisture-proof wrapping paper material, the raw materials of which include by weight: 80 parts of bark fiber, 10 parts of pineapple leaf fiber, 1 part of nano diatomite, 1 part of polyphenol antioxidant, and 5 parts of water-based polyurethane slurry.

[0019] Water-based polyurethane slurry raw materials include by weight: 80 parts of water-based polyurethane resin, 5 parts of fluorine-containing polyacrylic resin, 1 part of polyethylene wax, 1 part of thickener, 0.1 part of defoamer, 1 part of leveling agent, film-forming 2 parts of auxiliary agent.

[0020] The preparation method of the above-mentioned moisture-proof wrapping paper material comprises the following steps:

[0021] S1, beating the bark fiber, pineapple leaf fiber, and nanofiller to a beating degree of 32°SR to prepare a slurry;

[0022] S2, adding antioxidant to the slurry, after papermaking, cooling for 3 hours to obtain frozen papermaking;

[0023] S3. Coat the frozen paper with the water-based p...

Embodiment 2

[0025] A moisture-proof wrapping paper material, the raw materials of which include by weight: 120 parts of bark fiber, 20 parts of pineapple leaf fiber, 3 parts of nanometer molecular sieve, 3 parts of polyphenol antioxidant, and 10 parts of water-based polyurethane slurry.

[0026] Water-based polyurethane slurry raw materials include by weight: 120 parts of water-based polyurethane resin, 15 parts of fluorine-containing polyacrylic resin, 2 parts of polyethylene wax, 3 parts of thickener, 0.4 part of defoamer, 1.5 parts of leveling agent, film-forming 4 parts of additives.

[0027] The preparation method of the above-mentioned moisture-proof wrapping paper material comprises the following steps:

[0028] S1, beating the bark fiber, pineapple leaf fiber, and nanofiller to a beating degree of 25°SR to prepare a slurry;

[0029] S2, adding antioxidant to the slurry, after papermaking, cooling for 4 hours to obtain frozen papermaking;

[0030] S3. Coat the frozen paper with t...

Embodiment 3

[0032] A moisture-proof wrapping paper material, the raw materials of which include by weight: 100 parts of bark fiber, 15 parts of pineapple leaf fiber, 2 parts of nano-carbon fiber, 2 parts of polyphenol antioxidant, and 7 parts of water-based polyurethane slurry.

[0033] Water-based polyurethane slurry raw materials include by weight: 100 parts of water-based polyurethane resin, 10 parts of fluorine-containing polyacrylic resin, 1.5 parts of polyethylene wax, 2 parts of thickener, 0.2 parts of defoamer, 1.2 parts of leveling agent, film-forming 3 parts of auxiliary agent.

[0034] The preparation method of the above-mentioned moisture-proof wrapping paper material comprises the following steps:

[0035] S1, beating the bark fiber, pineapple leaf fiber, and nanofiller to a beating degree of 28°SR to prepare a slurry;

[0036] S2, adding antioxidant to the slurry, after papermaking, cooling for 3.5 hours to obtain frozen papermaking;

[0037] S3. Coat the frozen paper with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com