Simple and convenient preparation method of Cu-doped Co9S8 nanotube array for supercapacitor

A nanotube array and supercapacitor technology, which is applied in the field of preparation of Cu-doped Co9S8 nanotube arrays, can solve problems such as unreported research on nanotube arrays, and achieve the effects of easy control, efficient charge and discharge, and simple synthesis process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

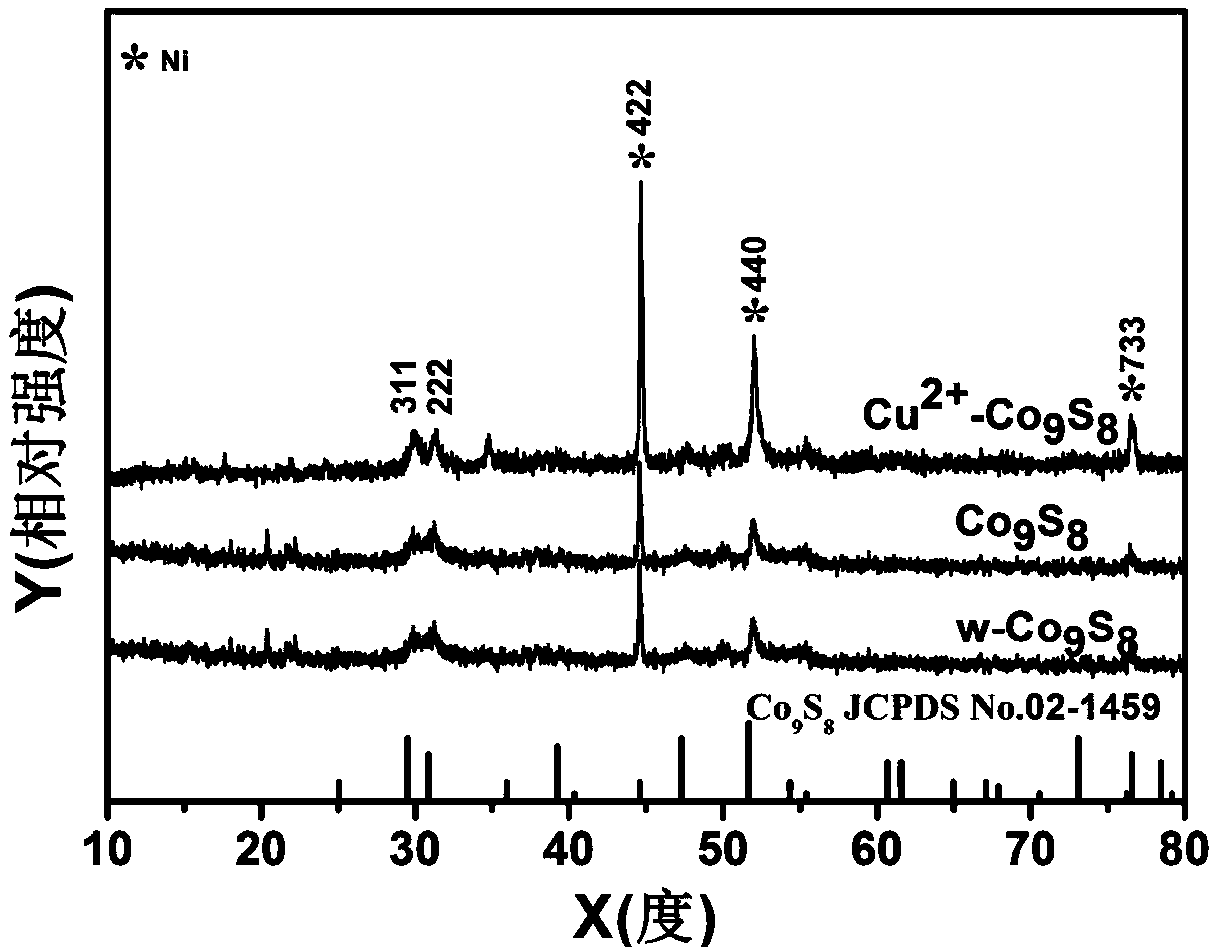

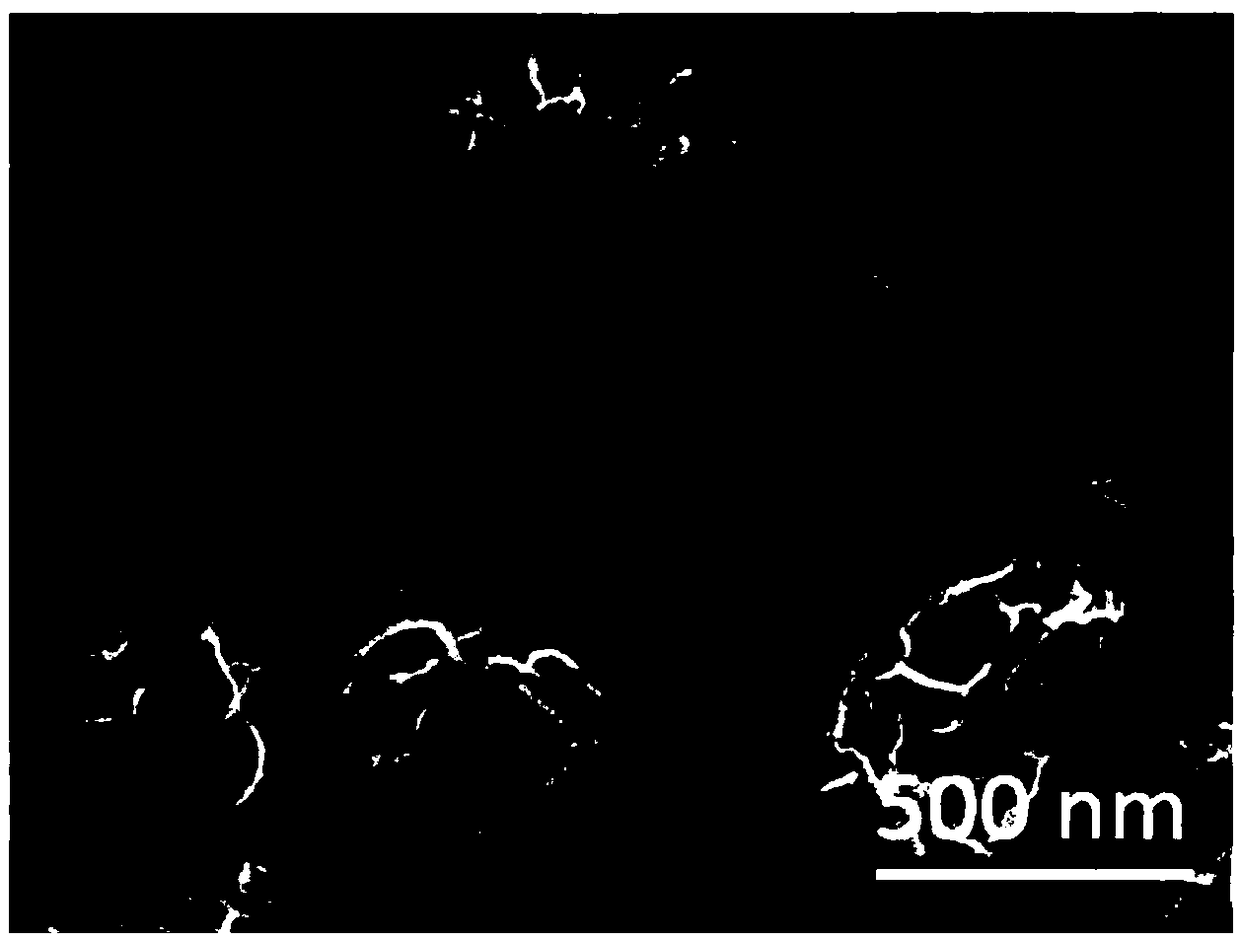

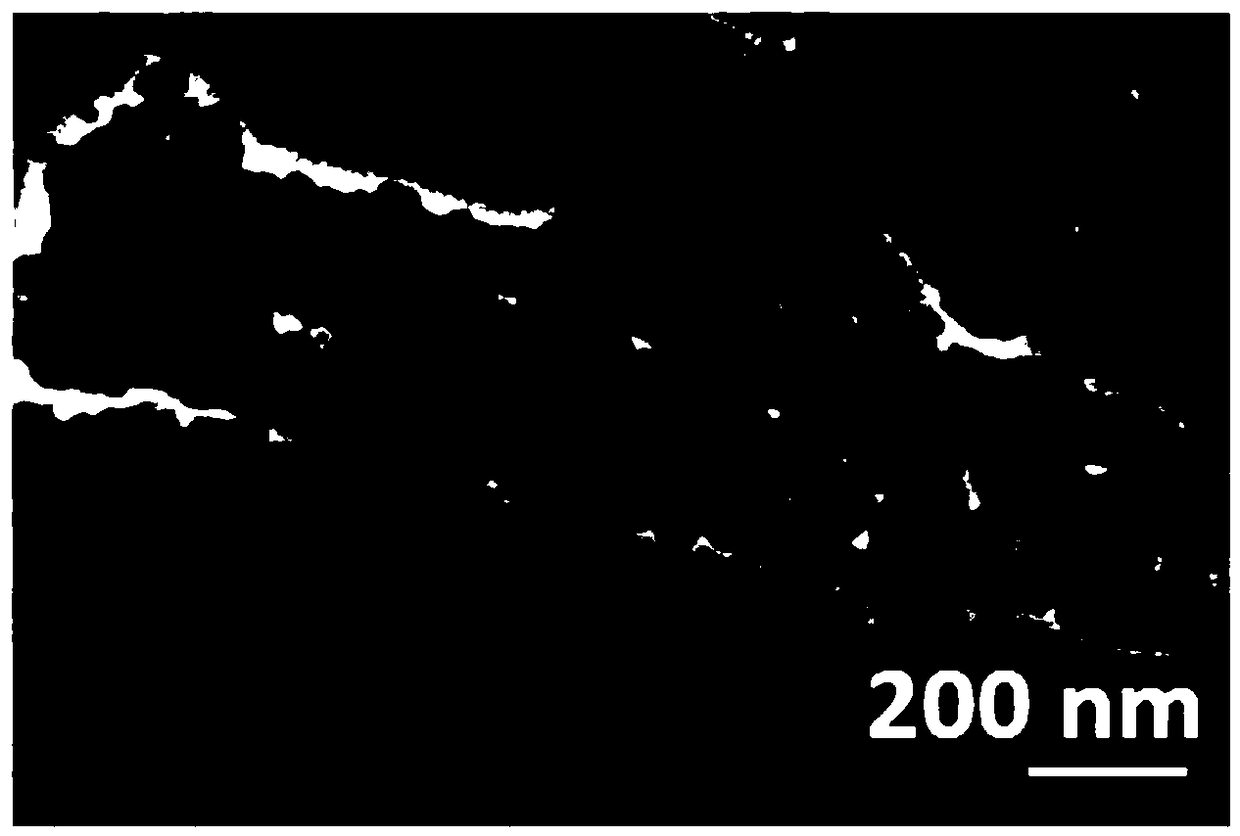

[0020] A Cu-doped Co for supercapacitor electrode material 9 S 8 Nanotube array preparation method, the preparation of Cu-doped Co 9 S 8 The method for arraying nanotubes comprises the steps of:

[0021] (1) Weigh 727mg of cobalt nitrate (Co(NO 3 ) 2 ·6H 2 O), 60mg of copper nitrate (Cu(NO 3 ) 2 ·3H 2 O), 750mg of urea (CO(NH 2 ) 2 ) was dissolved in 40ml of water, ultrasonically dispersed to form a homogeneous solution, and stirred for 30 minutes, the above-mentioned mixed solution was put into a 40mL reactor, and a piece of treated foam nickel (2cm×4cm) was added to the reactor. After reacting for 12 hours, open the reaction vessel after naturally cooling to room temperature, wash the foamed nickel with deionized water and absolute ethanol, and dry the foamed nickel to obtain Cu-doped Co(CO) grown on the foamed nickel substrate. 3 ) 0.5 (OH) nanorod arrays.

[0022] (2) Dissolve 30mg of trimesic acid in 10mL of water, 10mL of ethanol and 10mL of N,N-dimethylform...

Embodiment 2

[0029] (1) Weigh 727mg of cobalt nitrate (Co(NO 3 ) 2 ·6H 2 O), 750mg of urea (CO(NH 2 ) 2 ) was dissolved in 40ml of water, ultrasonically dispersed to form a homogeneous solution, and stirred for 30 minutes, the above-mentioned mixed solution was put into a 40mL reactor, and a piece of treated foam nickel (2cm×4cm) was added to the reactor. After reacting for 12 hours, open the reactor after cooling to room temperature naturally, wash the nickel foam with deionized water and absolute ethanol, and dry the nickel foam to obtain the Co(CO) grown on the nickel foam substrate. 3 ) 0.5 (OH) nanorod arrays.

[0030] (2) Dissolve 30mg of trimesic acid in 10mL of water, 10mL of ethanol and 10mL of N,N-dimethylformamide, and transfer it to the reaction kettle after ultrasonic dispersion, then add the Co(CO 3 ) 0.5 (OH) nanorod arrays, react at 150 ° C for 12 hours, open the reaction vessel after cooling to room temperature naturally, wash the foamed nickel with deionized water ...

Embodiment 3

[0035] (1) Weigh 727mg of cobalt nitrate (Co(NO 3 ) 2 ·6H 2 O), 60mg of copper nitrate (Cu(NO 3 ) 2 ·3H 2 O), 750mg of urea (CO(NH 2 ) 2 ) was dissolved in 40ml of water, ultrasonically dispersed to form a homogeneous solution, and stirred for 30 minutes, the above-mentioned mixed solution was put into a 40mL reactor, and a piece of treated foam nickel (2cm×4cm) was added to the reactor. After reacting for 12 hours, open the reaction vessel after naturally cooling to room temperature, wash the foamed nickel with deionized water and absolute ethanol, and dry the foamed nickel to obtain Cu-doped Co(CO) grown on the foamed nickel substrate. 3 ) 0.5 (OH) nanorod arrays.

[0036] (2) Take 0.18g of thioacetamide (TAA) and dissolve it in 40mL of ethanol, transfer it to the reaction kettle after ultrasonic dispersion, and then add the Cu-doped Co(CO 3 ) 0.5 (OH) nanorod array, react at 120°C for 4 hours, open the reactor after naturally cooling to room temperature, wash the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com