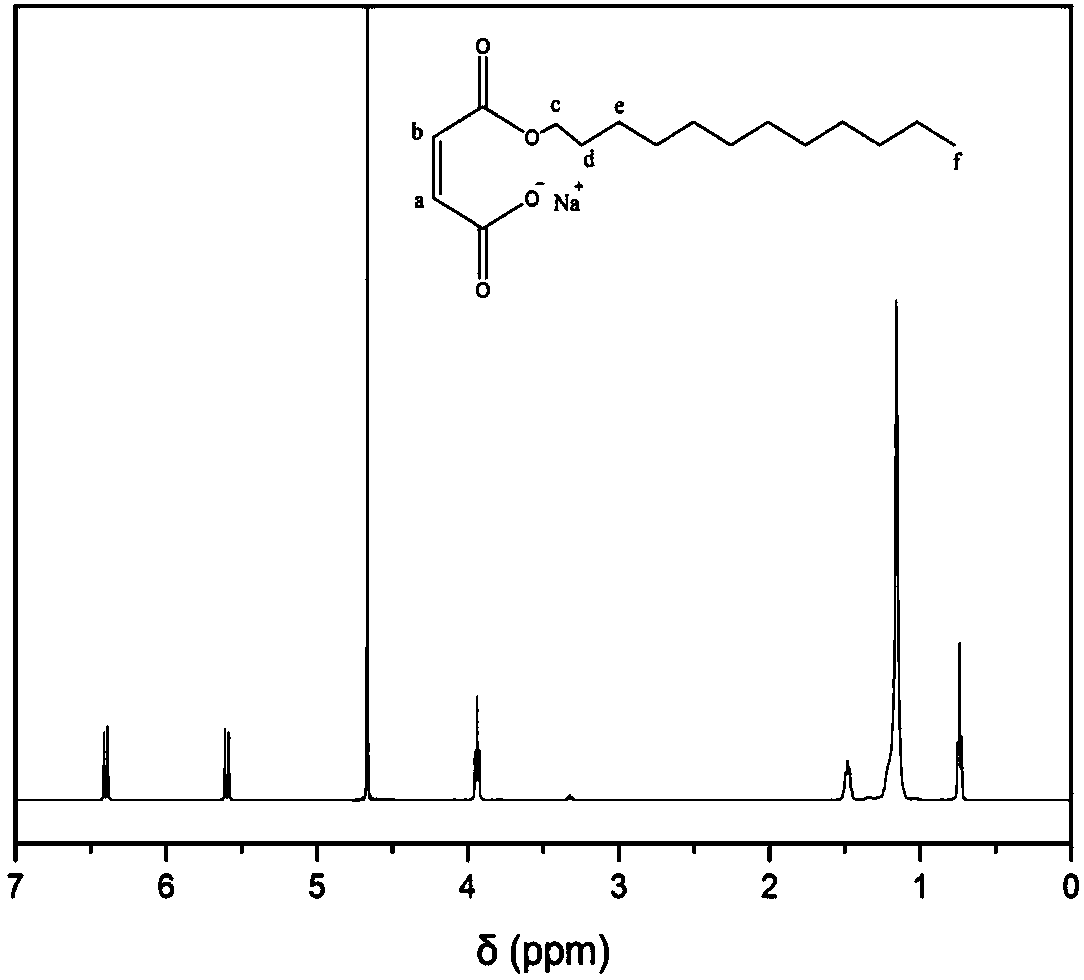

Polymethyl methacrylate-sodium maleic acid fatty alcohol ester-aluminum oxide nanocomposite material and preparation method thereof

A technology of polymethyl methacrylate and methyl methacrylate, which is applied in the field of polymethyl methacrylate-fatty alcohol maleate sodium salt-aluminum oxide nanocomposite material and its preparation field, can solve the problem of surface Strong effect, complex operation, easy agglomeration and other problems, achieve uniform and stable dispersion state, and solve serious agglomeration problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

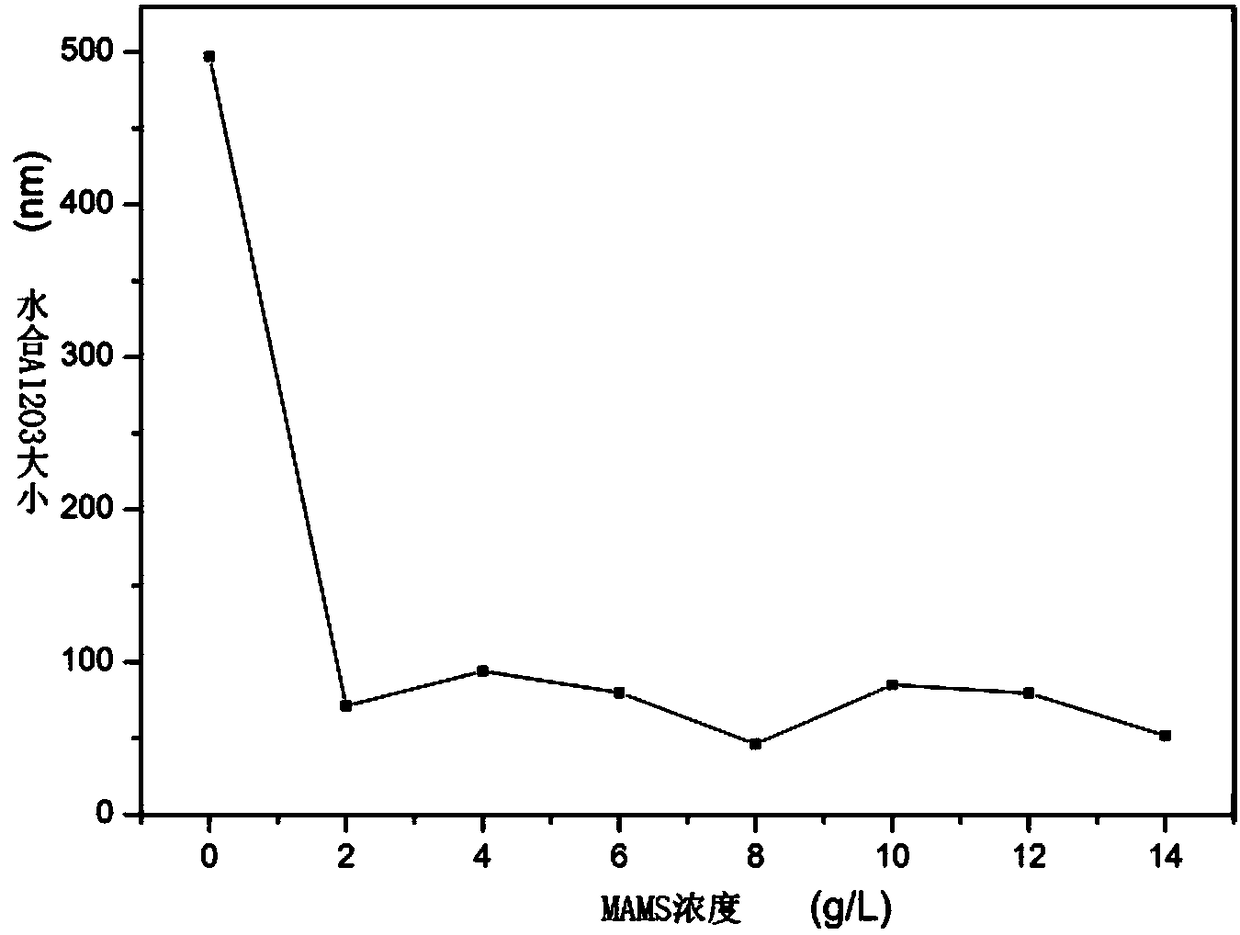

Method used

Image

Examples

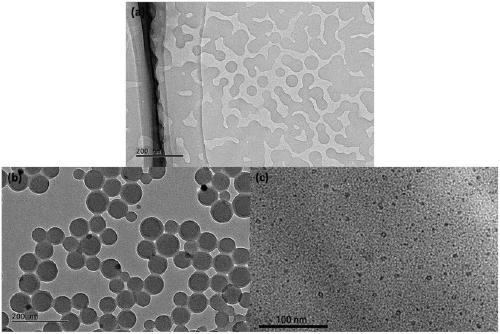

Embodiment 1

[0043] (1) Preparation of polymethyl methacrylate-alumina nanocomposite emulsion with anionic monomer MAMS as emulsifier: Weigh 0.5g MAMS, 0.057g initiator KPS, dissolve in 50mL deionized water, and then weigh Add 10g of monomeric methyl methacrylate into a 250mL four-neck flask, stir and pre-emulsify at a speed of 700rpm for 2h, and add the pre-emulsion to a constant pressure dropping funnel for use;

[0044] (2) Add 0.5g Al 2 o 3 Nanoparticles and 0.5g of anionic monomer MAMS were dispersed in 50mL of deionized water, and ultrasonically dispersed with a JY92-II N-type ultrasonic cell pulverizer. The set parameters were: power 600W, working time 3s, intermittent time 2s, ultrasonic in ice bath environment After 30 minutes, add the ultrasonic dispersion liquid into a 250mL four-necked flask; then weigh 10g of methyl methacrylate, add it to a 250mL four-necked flask, pre-emulsify in a water bath at room temperature for 0.5h, set the stirring speed to 700rpm, after 0.5h, start ...

Embodiment 2

[0048] (1) Preparation of polymethyl methacrylate-alumina nanocomposite emulsion with anionic monomer MAMS as emulsifier: Weigh 0.4g MAMS, 0.057g initiator AIBN, dissolve in 50mL deionized water, and then weigh Add 10g of monomeric methyl methacrylate into a 250mL four-neck flask, stir and pre-emulsify at a speed of 700rpm for 2h, and add the pre-emulsion to a constant pressure dropping funnel for use;

[0049] (2) Add 0.5g Al 2 o 3 Nanoparticles and 0.6g of anionic monomer MAMS were dispersed in 50mL of deionized water, and ultrasonically dispersed with a JY92-II N-type ultrasonic cell pulverizer. The set parameters were: power 600W, working time 3s, intermittent time 2s, ultrasonic in ice bath environment After 30 minutes, add the ultrasonic dispersion liquid into a 250mL four-necked flask; then weigh 10g of methyl methacrylate, add it to a 250mL four-necked flask, pre-emulsify in a water bath at room temperature for 0.5h, set the stirring speed to 700rpm, after 0.5h, start...

Embodiment 3

[0053] (1) Preparation of polymethyl methacrylate-alumina nanocomposite emulsion with anionic monomer MAMS as emulsifier: Weigh 0.6g MAMS, 0.057g initiator ABVN, dissolve in 50mL deionized water, and then weigh Add 10g of monomeric methyl methacrylate into a 250mL four-neck flask, stir and pre-emulsify at a speed of 700rpm for 2h, and add the pre-emulsion to a constant pressure dropping funnel for use;

[0054] (2) Add 0.5g Al 2 o 3 Nanoparticles and 0.4g of anionic monomer MAMS were dispersed in 50mL of deionized water, and ultrasonically dispersed with a JY92-II N-type ultrasonic cell pulverizer. The set parameters were: power 600W, working time 3s, intermittent time 2s, ultrasonic in an ice bath environment After 30 minutes, add the ultrasonic dispersion liquid into a 250mL four-necked flask; then weigh 10g of methyl methacrylate, add it to a 250mL four-necked flask, pre-emulsify in a water bath at room temperature for 0.5h, set the stirring speed to 700rpm, after 0.5h, st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com