Method for preparing carvacrol microcapsule antibacterial agent from attapulgite stabilized oil-in-water emulsion

A technology of oil-in-water emulsion and attapulgite, which is applied in microcapsule preparations, botany equipment and methods, chemicals for biological control, etc., can solve irritating odor, poor thermal stability of carvacrol, volatility, Limit the use efficiency and other issues, achieve high antibacterial persistence, solve long-term dependence on antibiotics, and prevent volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

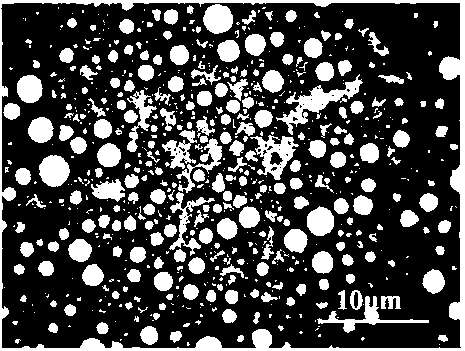

[0047] (1) Preparation of attapulgite-stabilized oil-in-water emulsion

[0048] Under the stirring condition of 200r / min, 50mL of 0.5 wt% sodium alginate solution was mixed with 30mL of 10 wt% attapulgite suspension to form a uniform suspension A;

[0049] 0.2g of Span 80 and 40g of carvacrol were fully mixed and emulsified, then added to 20mL of 20 wt% quaternized chitosan oligosaccharide solution, stirred at 150r / min for 30min to form solution B;

[0050] Add solution B to solution A, and stir and emulsify at 6000r / min for 60min to form attapulgite stable oil-in-water emulsion.

[0051] (2) Preparation of carvacrol microcapsules

[0052] Under slow stirring (30r / min), use a peristaltic pump to drop the attapulgite stable oil-in-water emulsion into 0.5 wt% calcium chloride solution, and the speed of the peristaltic pump is 3r / min; The formed microcapsules were separated, dried at 37°C, and packaged. The encapsulation efficiency of the obtained carvacrol microcapsules was 5...

Embodiment 2

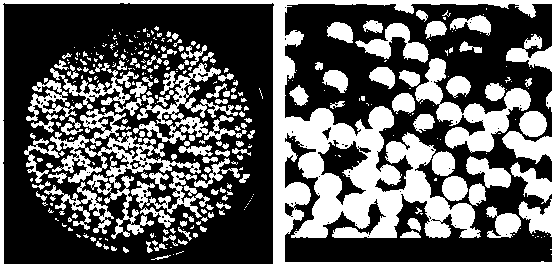

[0054] (1) Preparation of attapulgite-stabilized oil-in-water emulsion

[0055] Under the stirring condition of 150r / min, 50mL of 1.0 wt% sodium alginate solution was mixed with 50mL of 15 wt% attapulgite suspension to form a uniform suspension A;

[0056] After fully mixing 0.3g of Span 80 and 30g of carvacrol, add it to 10mL of 30 wt% quaternized chitosan solution, and stir at 250r / min for 20min to form solution B;

[0057] Add B to A and emulsify at 8000r / min for 30min to form attapulgite stable oil-in-water emulsion.

[0058] (2) Preparation of carvacrol microcapsules

[0059] Under slow stirring (40r / min), use a peristaltic pump to drop the attapulgite stable oil-in-water emulsion into 1.5 wt% calcium chloride solution, and the speed of the peristaltic pump is 4r / min; The formed microcapsules were separated, dried at 37°C, and packaged. The encapsulation efficiency of the obtained carvacrol microcapsules was 62.4%, and the oil content was 47.8%.

Embodiment 3

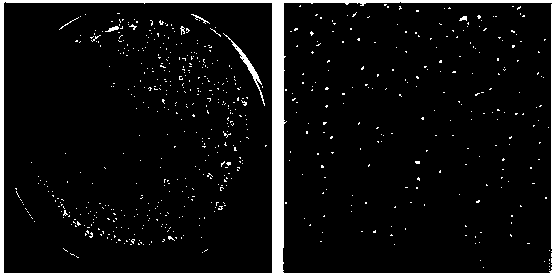

[0061] (1) Preparation of attapulgite-stabilized oil-in-water emulsion

[0062] Under the stirring condition of 200r / min, 50mL of 1.5 wt% sodium alginate solution was mixed with 40mL of 15 wt% attapulgite suspension to form a uniform suspension A.

[0063] After fully mixing 0.15g of Span 80 and 20g of carvacrol, add it to 20mL of 15 wt% quaternized chitosan solution, stir at 300r / min for 20min to form solution B;

[0064] Add B to A and emulsify at 7000r / min for 40min to form attapulgite stable oil-in-water emulsion.

[0065] (2) Preparation of carvacrol microcapsules

[0066] Under slow stirring (50r / min), use a peristaltic pump to drop the attapulgite stable oil-in-water emulsion obtained in step 1 into 2.0 wt% calcium chloride solution, and the speed of the peristaltic pump is 5r / min; After 20 minutes, the formed microcapsules were separated, dried at 37°C, and packaged. The encapsulation efficiency of the obtained carvacrol microcapsules was 65.5%, and the oil content ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com