Functional liquid milk containing fucoidin and preparation method of functional liquid milk

A fucoidan and functional technology, applied in the direction of dairy products, milk preservation, milk preparations, etc., can solve the problems of poor solubility of fucoidan, achieve effective absorption and utilization, functional improvement, and nutritional content improvement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

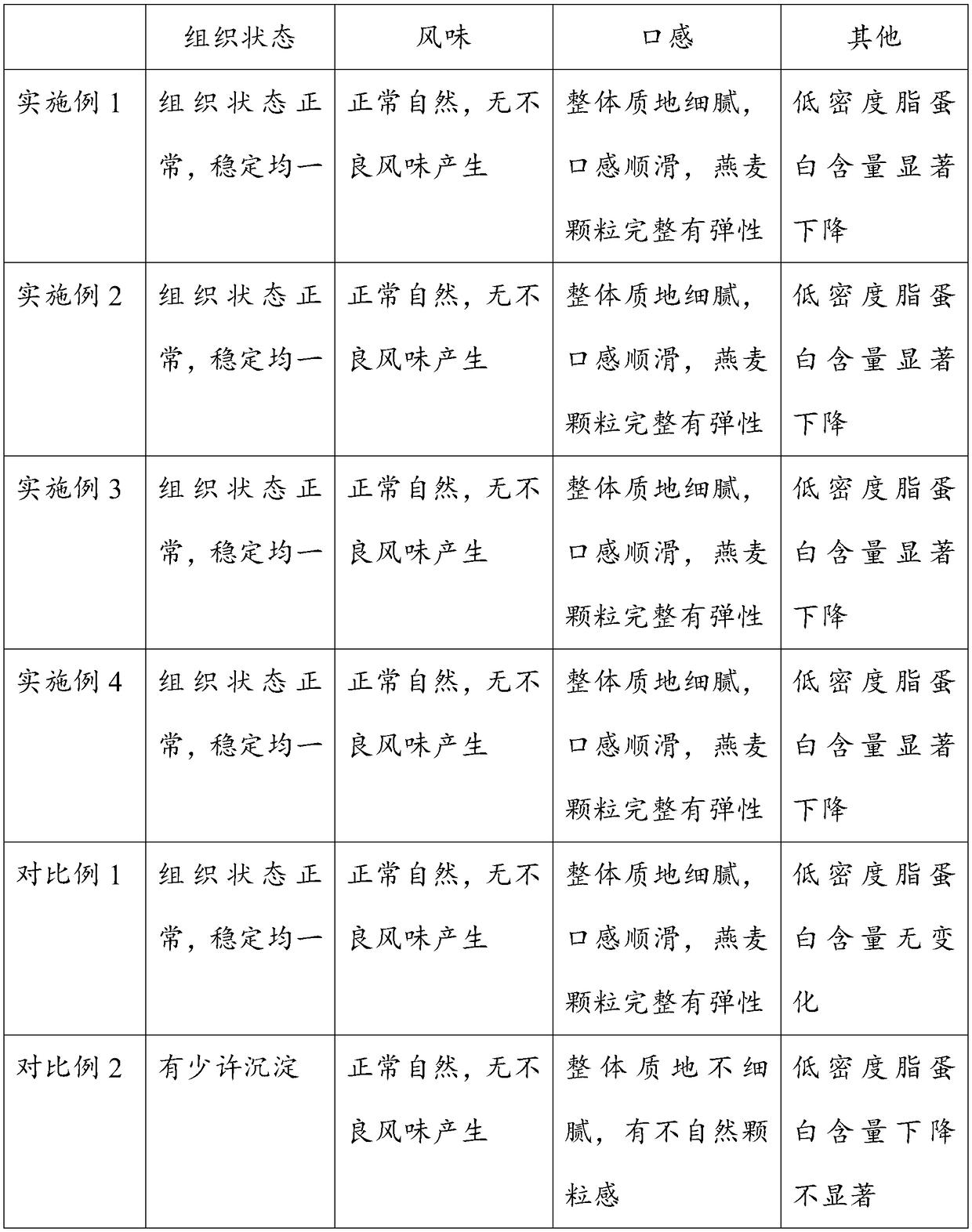

Examples

preparation example Construction

[0025] A preparation method of functional liquid milk containing fucoidan, the preparation method comprises the following raw materials: 1%-5% of oat, 0.01%-0.1% of vitamin E, 0.25%-0.5% of stabilizer, fucoidanase 5% to 8% of the solution and the raw milk supplemented to 100%, the percentage is the mass percentage of each raw material in the total raw material.

[0026] The preparation method comprises the following steps:

[0027] (1) adding oat, vitamin E, stabilizer and fucoidan enzymatic hydrolysis solution to raw milk in sequence, mixing, and homogenizing treatment to obtain feed solution; (2) adding the material obtained in step (1) The liquid is sterilized and cooled to obtain the functional liquid milk containing fucoidan.

[0028] In another specific embodiment, the enzymatic hydrolysis solution of fucoidan is obtained by enzymatic hydrolysis of fucoidan by using fucoidanase; the pH value of the enzymatic hydrolysis is 6.0-7.0, and the enzymatic hydrolysis time is 0....

Embodiment 1

[0040] A fucoidan-containing functional liquid milk, the preparation method comprising the following raw materials by mass: 89.4% of raw milk, 5% of oat, 0.1% of vitamin E, 0.5% of pectin, and 5% of enzymatic hydrolyzate of fucoidan .

[0041] The preparation method of the functional liquid milk comprises the following steps:

[0042](1) Enzymatically hydrolyze the fucoidan with fucoidanase, the enzymatic hydrolysis pH is 6.5, the enzymatic hydrolysis time is 1 h, and the enzymatic hydrolysis temperature is 35°C, and the fucoidan enzymatic hydrolysis solution is collected;

[0043] (2) Add oat, vitamin E, the fucoidan enzymatic hydrolysate obtained in step (1), and pectin in sequence to the raw milk, mix well at 55°C for 10 minutes, homogenize, and 18MPa at 60°C First-level homogenization, 3MPa second-level homogenization, to obtain feed liquid;

[0044] (3) Sterilize the feed liquid obtained in step (2) at 90° C. for 10 minutes, and cool it to 25° C. to obtain the fucoidan-...

Embodiment 2

[0046] A fucoidan-containing functional liquid milk, the preparation method of which comprises the following raw materials by mass percentage: raw milk 88.55%, oat 3%, vitamin E 0.05%, glycerol monostearate and soybean lecithin 0.4%, rock Algal polysaccharide hydrolyzate 8%.

[0047] The preparation method of the functional liquid milk comprises the following steps:

[0048] (1) Enzymatically hydrolyze the fucoidan by using fucoidanase, the enzymatic hydrolysis pH is 7, the enzymatic hydrolysis time is 0.5h, and the enzymatic hydrolysis temperature is 40°C, and the fucoidan enzymatic hydrolysis solution is collected;

[0049] (2) Add oats, vitamin E, the fucoidan enzymatic hydrolyzate solution obtained in step (1), glycerol monostearate and soybean lecithin into the raw milk in sequence, and mix well at 45°C for 15 minutes, and then uniform Quality treatment, 15MPa first-level homogenization and 5MPa second-level homogenization at 55°C to obtain feed liquid;

[0050] (3) Ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com